Flexible fibrous surface-treating article with low formaldehyde off-gassing

a flexible fibrous surface and off-gassing technology, which is applied in the field of flexible fibrous surface treatment articles with low formaldehyde off-gassing, can solve the problems of reduced physical properties such as strength and tensile modulus of alternate binder systems with lower off-gassing of formaldehyde, and achieves higher maximum load, better physical properties, and higher tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

n of Floor Pads

[0045]Webs were formed using a conventional web making machine (trade designation “Rando Webber”). The web formed was a blend of fibers including 75 weight percent of crimped polyethylene terephthalate (“PET”) staple fibers (50 denier, 58 mm long), and 25 weight percent of crimped sheath-core melt-bondable polyester staple fibers (15 denier, 58 mm long; with a core of polyethylene terephthalate and a sheath that was a copolymer of ethylene terephthalate and ethylene isophthalate). The formed web was heated in a convection oven for about 3 minutes at 320° F. (160° C.) to fuse the melt-bondable fibers together at points of intersection to form a prebond web. The prebond web weight was approximately 400 grams per square meter.

[0046]Samples of the prebond webs were cut to the dimensions of 1×7 inches in the cross-web direction (i.e. wherein the long dimension running sideways across the web as it is being made, rather than down-web). Samples were dipped in a curable compo...

example 2

yde Emissions

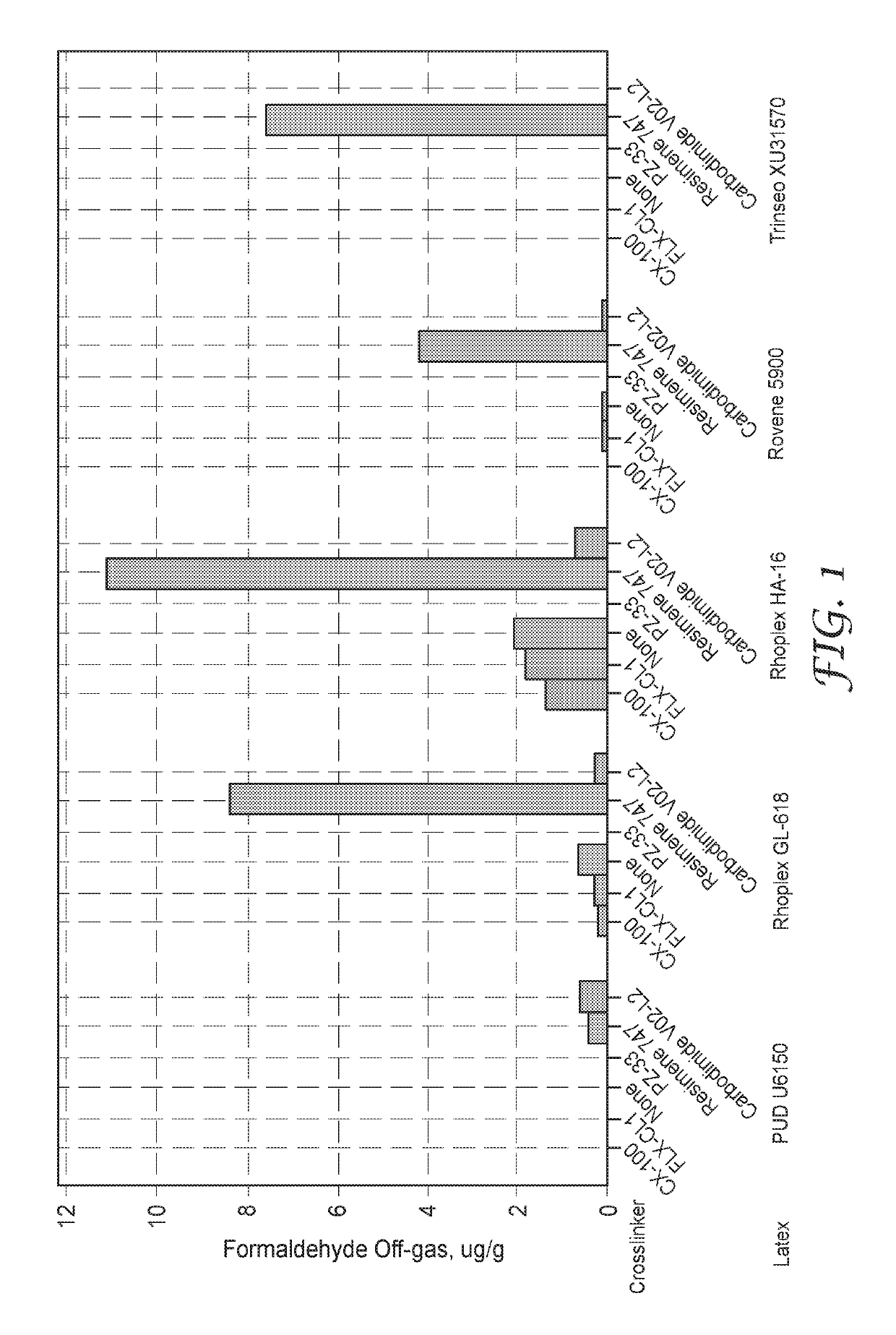

[0047]Formaldehyde emissions of the Samples made in Example 1 were measured. Emissions were measured by reaction with 2,4 dinitrophenylhydrazine [DNPH] to form the corresponding hydrazone, which was readily and sensitively detected by liquid chromatography. Sampling tubes containing silica gel impregnated with 2,4-DNPH were placed on a heated micro-chamber device having a volume of 44 mL (Marks micro-chamber), into which the coated non-woven sample was placed about 1 day to 1 week after the non-woven sample was finished curing and ready for packaging. The samples were heated to 65° C. (150° F.) for 30 minutes with a flow of helium at 50 mL / min passing through the sample chamber and into the collection tube. The tubes were then cut open and desorbed with 5 mL of acetonitrile, and the extract solution run by HPLC. The formaldehyde-DNPH content was determined from the standard calibration curve, and the formaldehyde concentration was calculated from the formaldehyde-DNPH r...

example 3

Properties at Room Temperature

[0051]The maximum load and tensile modulus of the Samples prepared in Example 1 were measured at room temperature. Tensile characterization was performed on an Instron tester, Model 59CP, with Bluehill 3 analysis software. Maximum load and modulus where determined at a jaw speed of 10 inches / minute. Samples were tested in triplicate.

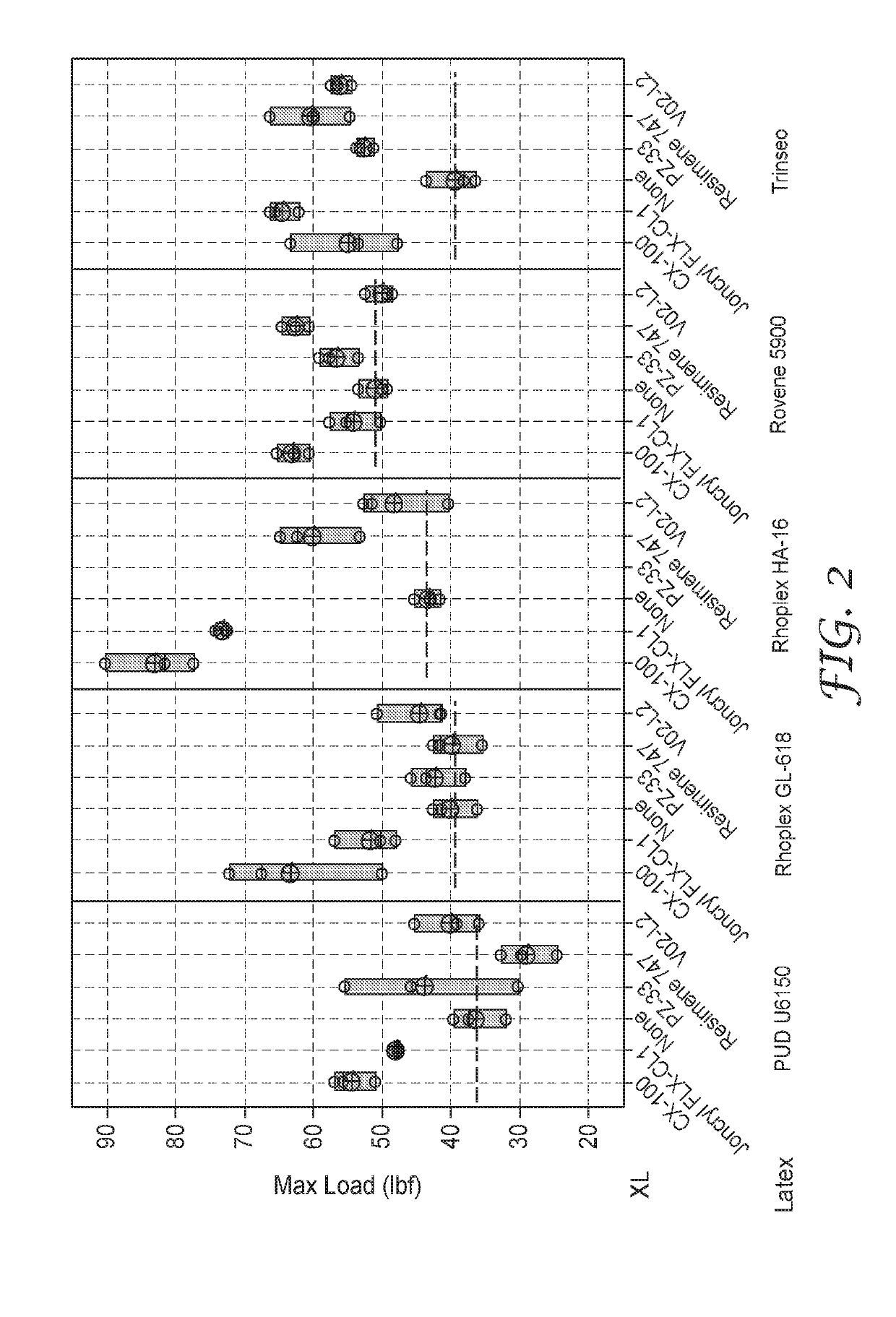

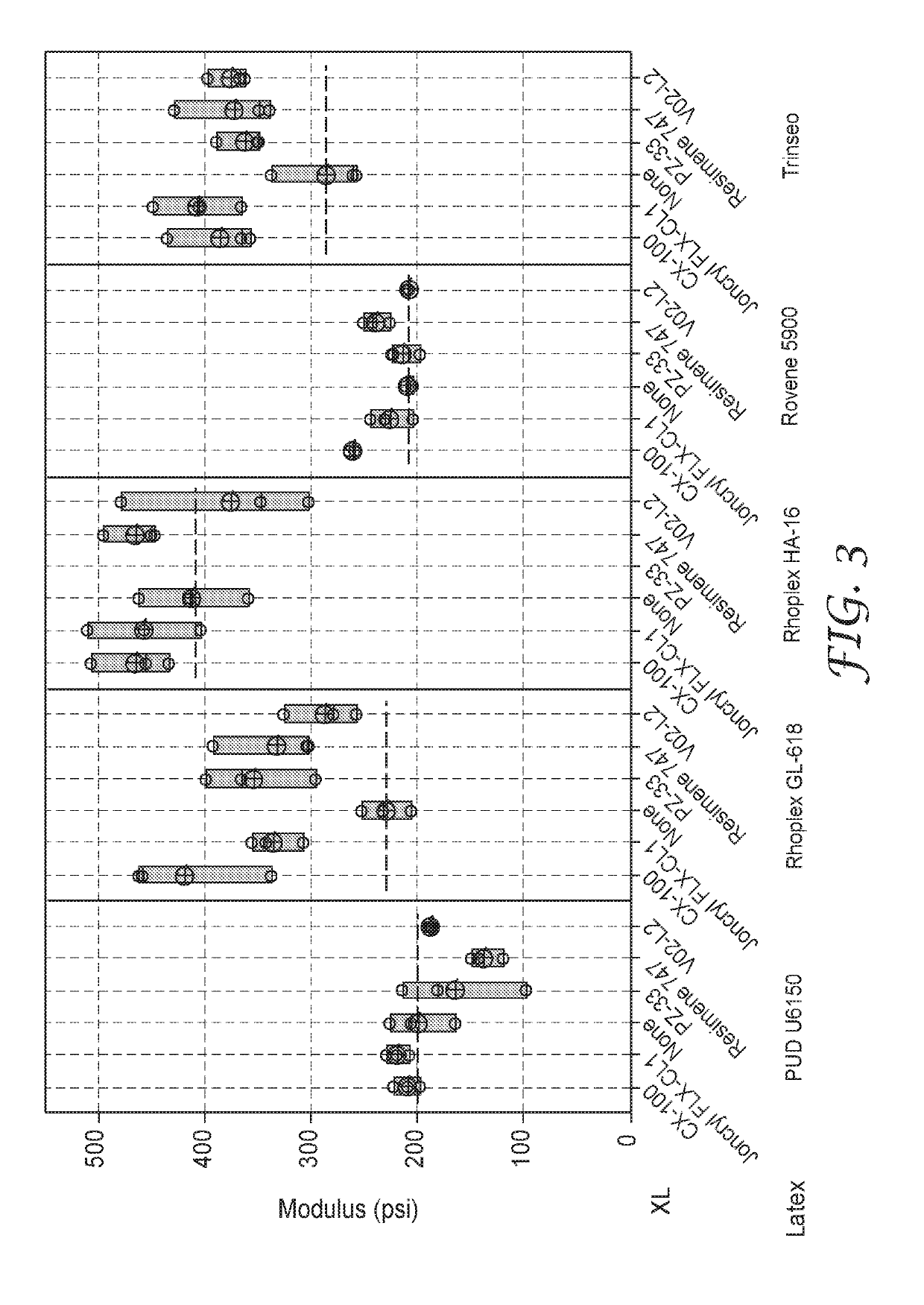

[0052]The maximum load and tensile modulus of the Samples is given in Table 4. Table 5 describes the change in maximum load caused by the crosslinker, as compared to crosslinker-free conditions. FIG. 2 illustrates the maximum load of the Samples at room temperature.

TABLE 4Maximum load and tensile modulusof Samples at room temperature.Avg Max LoadAvg ModulusLatexXL(lbf)(psi)Trinseo XU31570Resimene 74760.1371Trinseo XU31570V02-L255.9375Trinseo XU31570CX-10054.6386Trinseo XU31570Joncryl FLX-CL164.5406Rovene 5900Resimene 74762.4239Rovene 5900V02-L249.9207Rovene 5900CX-10062.8260Rovene 5900Joncryl FLX-CL154.1225Rhoplex HA-16Resim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com