M-MnOx-CeO2 catalyst and application thereof

A technology of m-mnox-ceo2 and catalyst, applied in M-MnOx-CeO2 catalyst and its application field, can solve the problems of limited scale application, preparation cost, catalyst stability, few industrial applications, etc., to solve the problem of indoor formaldehyde pollution , good thermal stability and high catalytic oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

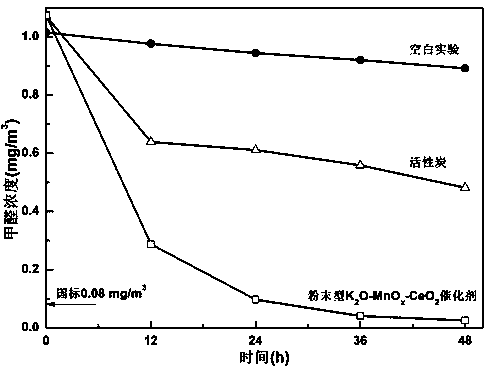

Embodiment 1

[0029] Take an appropriate amount of manganese nitrate solution, add an appropriate amount of distilled water, then take an appropriate amount of solid cerium nitrate and dissolve it in the above solution, stir until completely dissolved, wherein the Mn / Ce molar ratio is 6:1, then add an appropriate amount of potassium carbonate, and stir until completely dissolved, its K 2 The load of O is 1wt%, and then add an appropriate amount of citric acid solid into the above solution, stir until it is completely dissolved, the molar ratio of metal ion to citric acid is 6:1, put the above solution in a water bath at 80°C for cooking, and make it into In the form of a sol, take it out and place it in a stainless steel reactor with a polytetrafluoroethylene liner, and place the reactor in an oven at 100°C for aging for 24 hours, then take out the sample and place it in an oven at 100°C for 5 hours to dry, then put The above-mentioned solid is ground into powder, and then roasted at 350°C ...

Embodiment 2

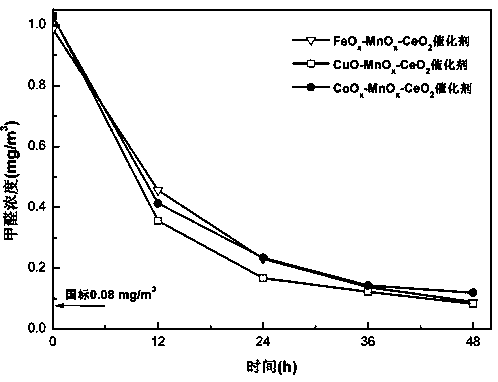

[0032] Take an appropriate amount of manganese nitrate solution, add an appropriate amount of distilled water, then take an appropriate amount of solid cerium nitrate and dissolve it in the above solution, stir until completely dissolved, wherein the Mn / Ce molar ratio is 4:1, then add an appropriate amount of ferric nitrate, and stir until completely dissolved, The molar ratio of Fe / Ce is 1:2, then add an appropriate amount of solid citric acid into the above solution, stir until it is completely dissolved, the molar ratio of metal ions to citric acid is 12:1, put the above solution in a water bath at 80°C for cooking, Make it into a sol, take it out and put it in a stainless steel reactor with a polytetrafluoroethylene liner, and put the reactor in an oven at 120°C for aging for 24 hours, then take out the sample and put it in an oven at 100°C for 5 hours to dry , and then grind the above solid into powder, and roast at 550°C for 7 hours to obtain powder FeO x -MnO x -CeO 2...

Embodiment 3

[0034] Take an appropriate amount of manganese nitrate solution, and add an appropriate amount of distilled water, then take an appropriate amount of solid cerium nitrate and dissolve it in the above solution, stir until it is completely dissolved, wherein the Mn / Ce molar ratio is 2:1, then add an appropriate amount of copper nitrate, and stir until completely dissolved, The molar ratio of Cu / Ce is 1:1, then add an appropriate amount of solid citric acid into the above solution, stir until it is completely dissolved, the molar ratio of metal ions to citric acid is 18:1, put the above solution in a water bath at 80°C for cooking , make it into a sol, take it out and put it in a stainless steel reactor with a polytetrafluoroethylene liner, and put the reactor in a 140°C oven for aging for 24h, then take out the sample and place it in an oven at 100°C for 5h Dry, then grind the above solid into powder, and roast at 650°C for 7h to obtain powder CuO-MnO x -CeO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com