Device and method of visible light photocatalytic degradation of gaseous formaldehyde with dye-sensitized TiO<2>

A dye sensitization, gas formaldehyde technology, applied in the field of photocatalysis, achieves high formaldehyde degradation efficiency, simple operation, and the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

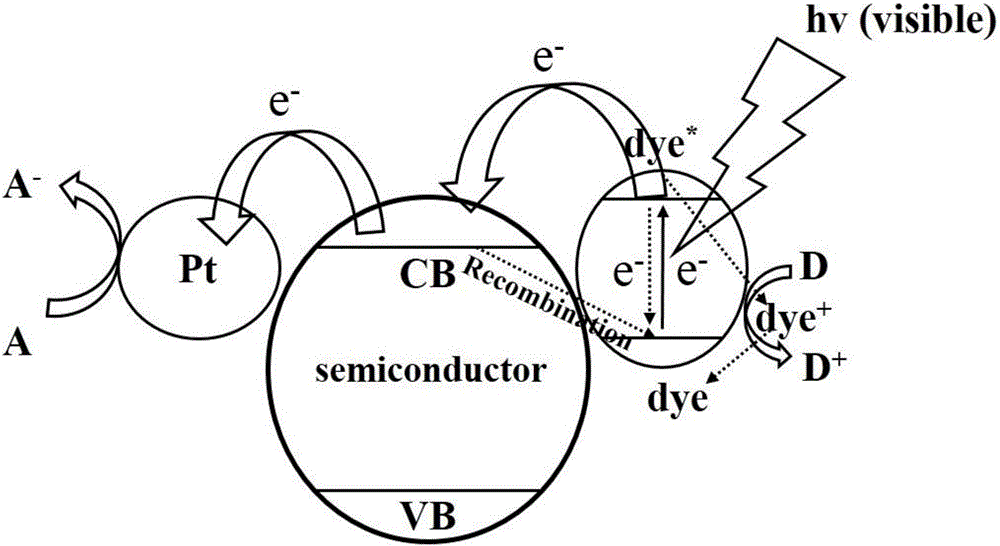

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] (3) Preparation of gaseous formaldehyde and detection of its concentration: first measure a certain amount of formaldehyde solution (36% formalin solution) and quickly place it in the reaction device and seal it away from light. After the formaldehyde solution is vaporized, use a gas sampler to extract a certain amount of formaldehyde gas into a gas absorption bottle with a certain amount of distilled water. The best sampling time for the initial concentration of formaldehyde is 3 hours after vaporization, and the measured initial formaldehyde concentration is 7.0mg / m 3 , this method has better selectivity and repeatability, and lower testing cost. The determination method of the degraded formaldehyde concentration is consistent with the above. TiO sensitized with three different dyes 2 The size of the working area of the film is basically the same, about 7.1×10 -5 g / cm 2 , Humidity maintained in the range of 50% to 60%. The light time of the experiment was 12 hou...

Embodiment 1

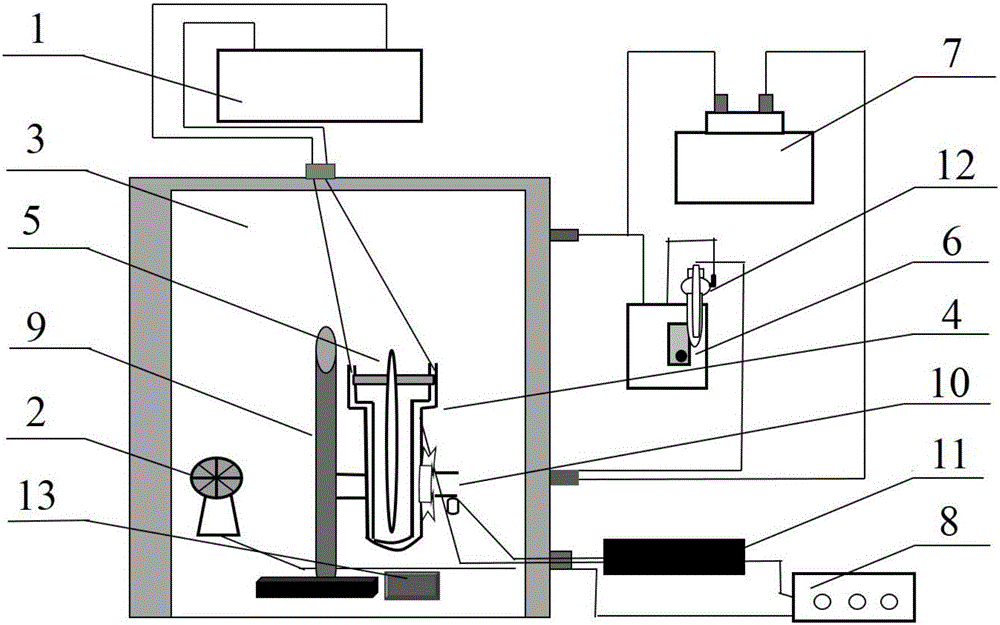

[0064] (1) Reaction device: Considering factors such as environmental protection, economy and applicability, combined with the above-mentioned factors affecting the design of photocatalytic reactor, the final self-designed figure 1 The experimental reaction setup is shown. Visible light catalytic degradation formaldehyde reaction device is a customized size of 50cm × 50cm × 80cm, the actual capacity is V 0 =0.3485m 3 The stainless steel cubic container is equipped with an interface for connecting a formaldehyde gas sampler, through which the gas sampler will extract the formaldehyde gas in the container, and then perform concentration detection. Considering factors such as the fluidity of the gas, the temperature and humidity of the system, a fan, a xenon lamp, and a probe of a temperature and humidity meter are placed inside the reaction device. In order to better control the temperature of the system and prolong the service life of the light source, a cold trap is placed i...

Embodiment 2

[0069] (1) Use a self-designed reaction device and explore the stability of the device. The specific method is as in (1) and (2) steps in Example 1.

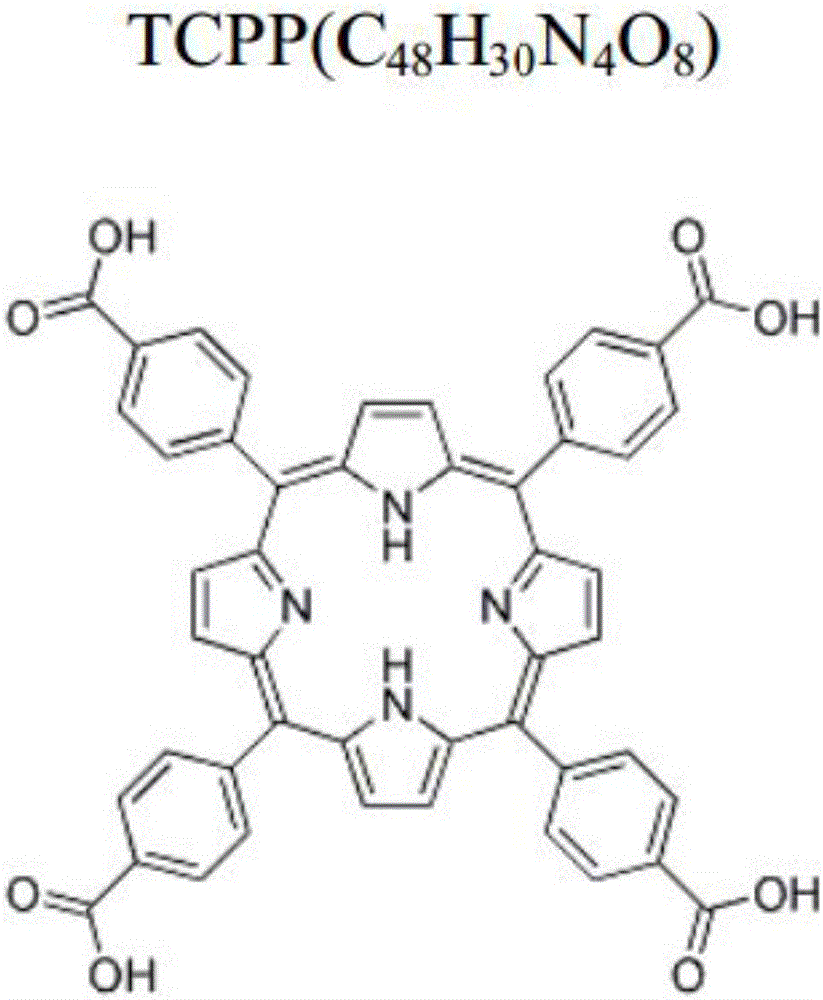

[0070] (2) Using TCPP as TiO 2 Films of dye sensitizers were then subjected to subsequent experiments.

[0071] (3) The national standard "HJ 601-2011: Determination of water quality-formaldehyde, acetylacetone spectrophotometry" was used to measure the gas formaldehyde concentration. The specific operation was to measure a certain amount of formaldehyde solution (36% formalin solution) quickly Put it in the reaction device and seal it away from light, and then heat the reaction device containing the formaldehyde solution. After the formaldehyde is completely vaporized, use a gas sampler to extract a certain amount of formaldehyde gas into a gas absorption bottle with a certain amount of distilled water. The sampling time point is to measure the initial formaldehyde concentration when the gasification is complete for 3 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com