Preparation method of polyoxymethylene dimethyl ether (DMMn)

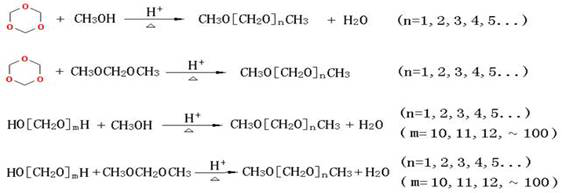

The technology of polymethoxydimethyl ether and polyoxymethylene is applied in the field of preparation of polymethoxydimethyl ether (DMMn, generally n=3-8), which can solve problems such as unfavorable industrialization, blockage of transmission pipelines, influence and the like, To achieve the effect of good catalytic effect, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

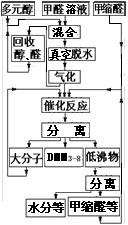

Method used

Image

Examples

Embodiment 1

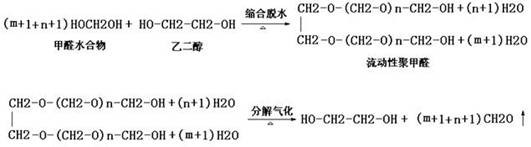

[0027] Example 1: After mixing 400g of formaldehyde aqueous solution (37%) and 60g of ethylene glycol, vacuumize and heat to remove moisture to obtain 193.2g of anhydrous flowing polyoxymethylene, and then gradually heat the anhydrous flowing polyoxymethylene to 160 ℃, formaldehyde is gradually gasified to form gaseous formaldehyde, and then dry anhydrous gaseous formaldehyde is passed into a mixture of 10g catalyst and 280g methylal, and a catalytic reaction occurs at a certain temperature. After the reaction reaches equilibrium, the catalyst is filtered out to obtain Reaction equilibrium liquid 356.7g, residual ethylene glycol 91.7g (a total loss of 24.8g), and then the reaction equilibrium liquid 356.7g were subjected to normal pressure and vacuum distillation respectively, and 250.8g of low boilers, 15.5g of macromolecules and DMMn finished product were separated 72.4g (loss of 18.0g), DMMn finished product is then subjected to vacuum distillation to obtain each single comp...

Embodiment 2

[0028] Example 2: After mixing 400g of formaldehyde aqueous solution (37%) and 91g of ethylene glycol recovered from the previous batch, vacuumize and heat to remove moisture, and obtain 222.5g of anhydrous mobile polyoxymethylene, and then anhydrous mobile polyoxymethylene After gradually heating to 160°C, the formaldehyde is gradually gasified to form gaseous formaldehyde, and then the dry anhydrous gaseous formaldehyde is passed into a mixture of 10g catalyst and 280g methylal, and a catalytic reaction occurs at a certain temperature. After the reaction reaches equilibrium, The catalyst was filtered out to obtain 384.7g of reaction equilibrium liquid and 93.5g of residual ethylene glycol (a total loss of 24.3g), and then 384.7g of reaction equilibrium liquid were subjected to normal pressure and reduced pressure distillation respectively, and 264.0g of low boilers and macromolecular 22.9g and DMMn finished product 77.3g (loss 20.5g), the DMMn finished product is subjected to...

Embodiment 3

[0029] Example 3: After mixing 400g of formaldehyde aqueous solution (37%) and 93.5g of ethylene glycol recovered from the previous batch, vacuumize and heat to remove moisture to obtain 226.7g of anhydrous mobile polyoxymethylene, anhydrous mobile polyoxymethylene After gradually heating to 160°C, the formaldehyde is gradually gasified to form gaseous formaldehyde, and then the dry and anhydrous gaseous formaldehyde is passed into a room containing 10g of catalyst, 264.0g of recovered low boiling matter, 22.9g of macromolecules and 196g of methylal. In the mixture, a catalytic reaction occurs at a certain temperature. After the reaction reaches equilibrium, the catalyst is filtered out to obtain 593.6 g of reaction equilibrium liquid and 90.0 g of residual ethylene glycol (a total loss of 26 g). and vacuum distillation to separate out 397.3g of low boilers, 35.5g of macromolecules and 128.8g of finished DMMn (loss of 32.0g). The finished DMMn is then subjected to vacuum distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com