Device and method for producing high-concentration formaldehyde by using methanol

A kind of methanol, product technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

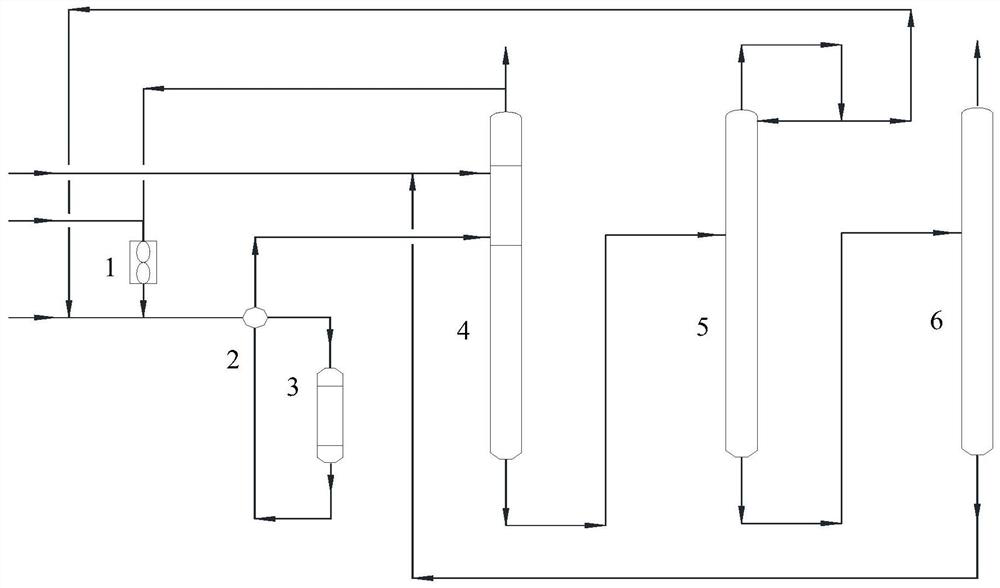

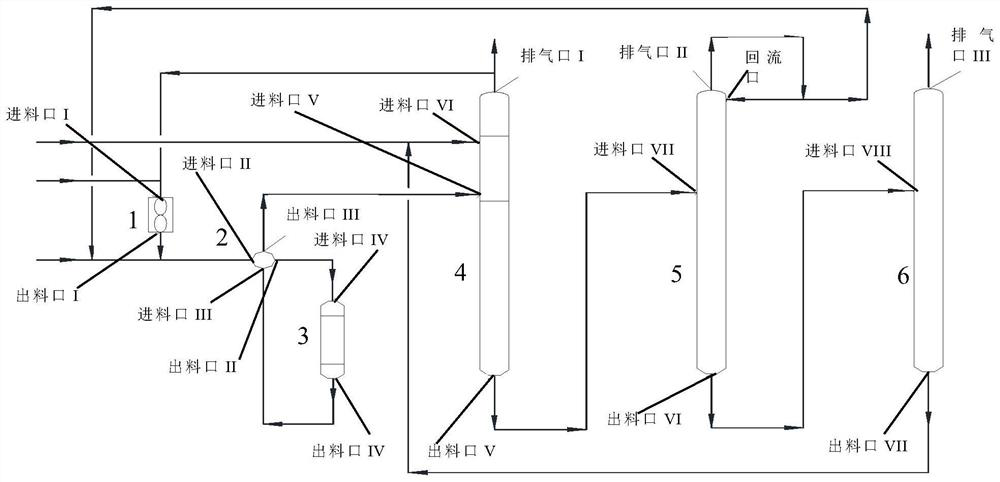

Image

Examples

Embodiment 1

[0063] A method utilizing methanol to produce high-concentration formaldehyde, specifically comprising the following steps:

[0064] (1) Oxidation reaction: After the air is pressurized by the fan 1, the qualified product of industrial methanol (GB 338-2011) is used as a raw material. After the methanol is vaporized, it is mixed with the air at a volume ratio of 6:100 and then flows through the heat exchanger 2 After that, feed inlet IV (volume space velocity is 5h -1 ) into the fixed-bed reactor 3, air and methanol are oxidized under the catalysis of catalyst A (comprising iron molybdate and molybdenum trioxide, molybdenum, iron molar ratio is 3:1) in the fixed-bed reactor 3 Reaction, the reaction temperature is 345-350°C, the reaction pressure is 0.18-0.20Mpa, and the primary reaction product is obtained; the primary reaction product is a mixture of formaldehyde, unreacted methanol, formic acid and water. The primary reaction product flows through the discharge port IV and ...

Embodiment 2

[0071] A method utilizing methanol to produce high-concentration formaldehyde, specifically comprising the following steps:

[0072] (1) Oxidation reaction: After the air is pressurized by the fan 1, and the qualified product of industrial methanol (GB 338-2011) is used as a raw material, the volume ratio of vaporized methanol vapor to air is 5.5:100, and the mixture flows through the heat exchanger After 2, feed port IV (volume space velocity is 5h -1 ) into the fixed bed reactor 3, air and methanol carry out oxidation reaction under the catalysis of catalyst A (same as embodiment 1) in the fixed bed reactor, the reaction temperature is 345~350 ℃, and the reaction pressure is 0.18 ~0.20Mpa, the primary reaction product is obtained; the primary reaction product is a mixture of formaldehyde, unreacted methanol, formic acid, and water. The primary reaction product flows through the discharge port IV and the feed port III in sequence, enters the heat exchanger 2 for heat exchang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com