A 4,6-dihydroxypyrimidine reaction system tail gas treatment process

A technology of dihydroxypyrimidine and reaction system, which is applied in the field of tail gas treatment technology of 4,6-dihydroxypyrimidine reaction system, can solve the problems of incomplete recovery, unsafe, waste of resources, etc., and achieves alleviation of air pollution, good safety performance, The effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

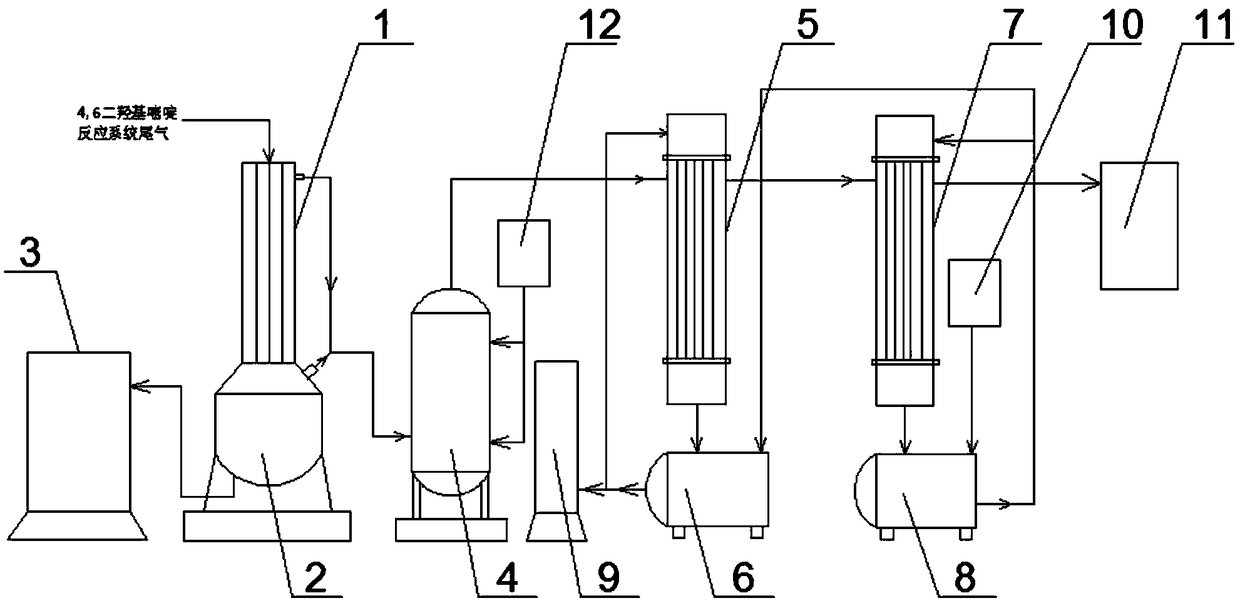

[0019] Embodiment 1, as figure 1 Shown, the specific operation steps of described technology are as follows:

[0020] A. Methanol recovery: the tail gas of the 4,6-dihydroxypyrimidine reaction system containing 5.36% methanol and 0.91% ammonia is 750m 3 The flow rate of / h is input into the condenser 1, and the temperature in the condenser 1 is lowered to -5°C-0°C with low-temperature cold water, the gaseous methanol in the tail gas is condensed into liquid methanol, and the liquid methanol is diverted to the receiving tank 2 for collection, and then Liquid methanol is delivered to the methanol raw material tank 3, and 600kg of methanol is recovered every day;

[0021] B, nitrogen protection: the tail gas after removing methanol is input in the surge tank 4, and nitrogen is input into the surge tank 4 by the nitrogen supply equipment 12, so that the pressure in the surge tank 4 remains at 0.02-0.03MPa;

[0022] C, ammonia recovery: the tail gas output by the surge tank 4 is ...

Embodiment 2

[0024] Embodiment 2, the specific operation steps of described technique are as follows:

[0025] A. Methanol recovery: the tail gas of the 4,6-dihydroxypyrimidine reaction system containing 4.87% methanol and 0.74% ammonia is 800m 3 The flow rate of / h is input into the condenser 1, and the temperature in the condenser 1 is lowered to 0°C-5°C with low-temperature cold water, the gaseous methanol in the tail gas is condensed into liquid methanol, and the liquid methanol is diverted to the receiving tank 2 for collection, and then Liquid methanol is delivered to the methanol raw material tank 3, and 450kg of methanol is reclaimed every day;

[0026] B, nitrogen protection: the tail gas after removing methanol is input in the surge tank 4, and nitrogen is input in the surge tank 4, so that the pressure in the surge tank 4 remains at 0.02-0.025MPa;

[0027] C, ammonia recovery: the tail gas output by the surge tank 4 is delivered to the first-level falling film absorber 5, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com