Adhesive-free non-photocatalytic diatom ooze material for removing gaseous formaldehyde in air

A catalytic purification and diatom mud technology, applied in the field of diatomite wall materials, can solve the problems of loss of filtration and adsorption function, poor viscosity of diatomite, moisture loss and other problems, and achieve large adsorption capacity, high porosity, good durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

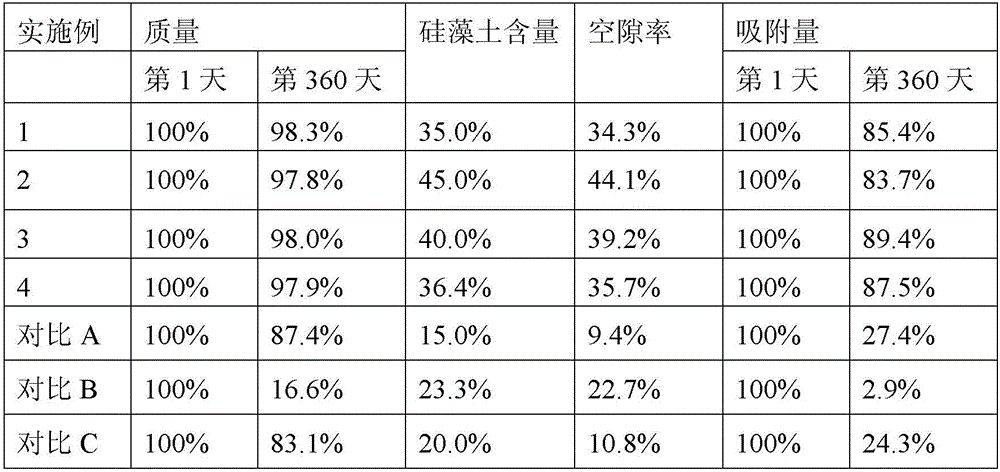

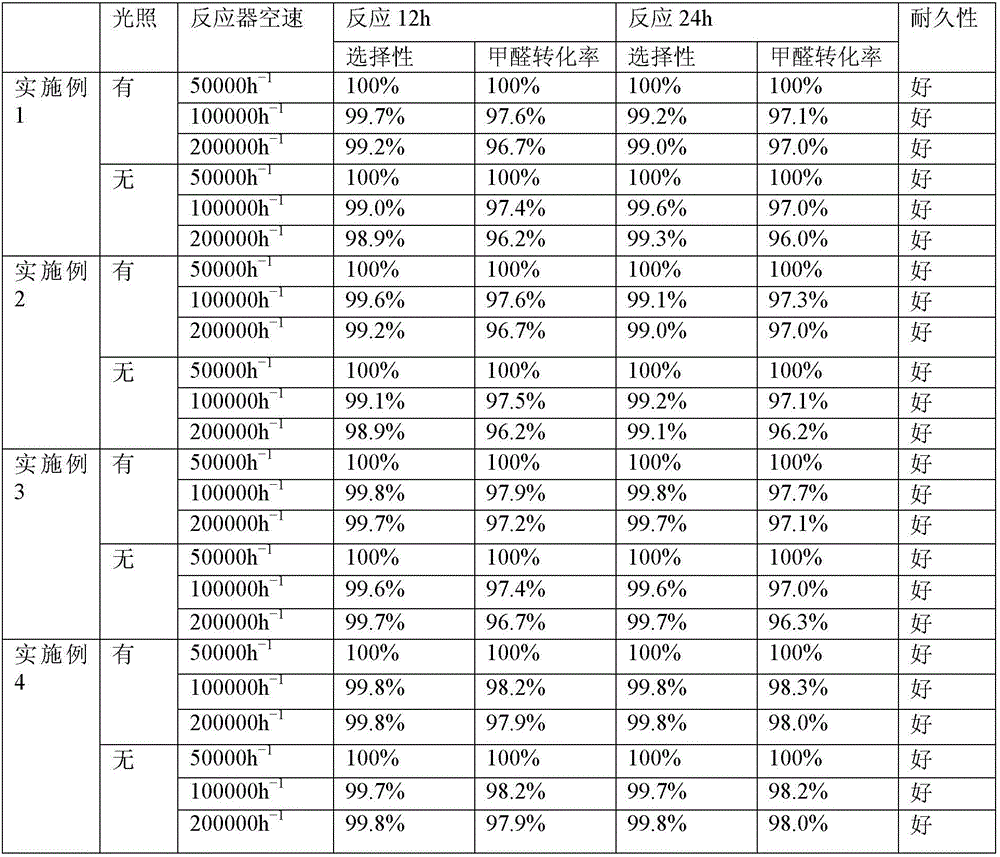

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: the diatom ooze material of this embodiment non-glue type non-photocatalytic purification airborne formaldehyde is made up of diatomite of 35~45 parts, brucite powder of 8~12 parts, 4~ 6 parts of illite powder, 4-6 parts of attapulgite, 4-6 parts of hydroxypropyl methylcellulose, 13-17 parts of starch, 4-6 parts of opal stone powder, 8-12 parts of lanthanum It is made of element oxide powder and 4-6 parts of nano silicon dioxide.

[0013] In this embodiment, the preparation method of the diatom ooze material for the non-photocatalytic purification of airborne formaldehyde without glue: weigh diatomite, brucite powder, illite powder, attapulgite, and hydroxypropyl methylate according to the weight and number ratio. base cellulose, starch, opal stone powder, lanthanide oxide powder and nano silicon dioxide, then put the opal stone powder, lanthanide oxide powder and nano silicon dioxide into a dry powder mixer and stir at a high speed to obtain 1 ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the diatom ooze material of non-photocatalytic purification of airborne air formaldehyde in this embodiment is composed of 40 parts of diatomite, 10 parts by weight. 4 parts of brucite powder, 5 parts of illite powder, 5 parts of attapulgite, 5 parts of hydroxypropyl methylcellulose, 15 parts of starch, 5 parts of opal stone powder, 10 parts of lanthanide oxide It is made of material powder and 5 parts of nano-silica.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the diatomite wall material also includes 4 to 6 parts of nano rhodochrosite powder and 4 to 6 parts of nanometer rhodochrosite powder in parts by weight. copper. Other steps and parameters are the same as those in Embodiment 1 or 2.

[0018] This embodiment can accelerate the decomposition of formaldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com