Chain cutter type mixing pile wall forming equipment

A wall-forming equipment and a technology of mixing piles, applied in the field of pile foundation engineering, can solve problems such as difficulty in meeting actual construction requirements, uneven strength of formed pile walls, difficulty in meeting pile walls, etc., and achieve wide adaptability, good waterproof performance, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

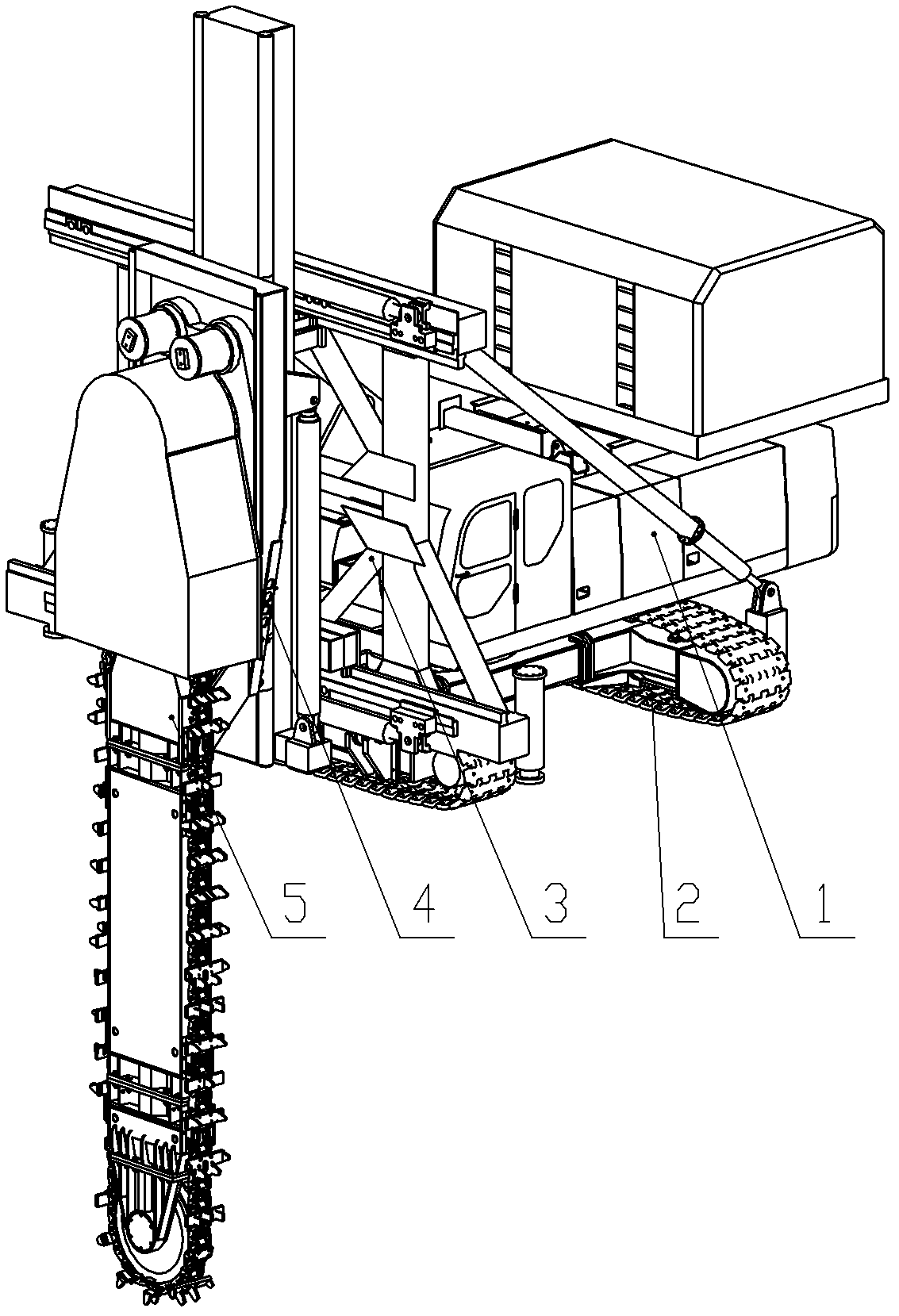

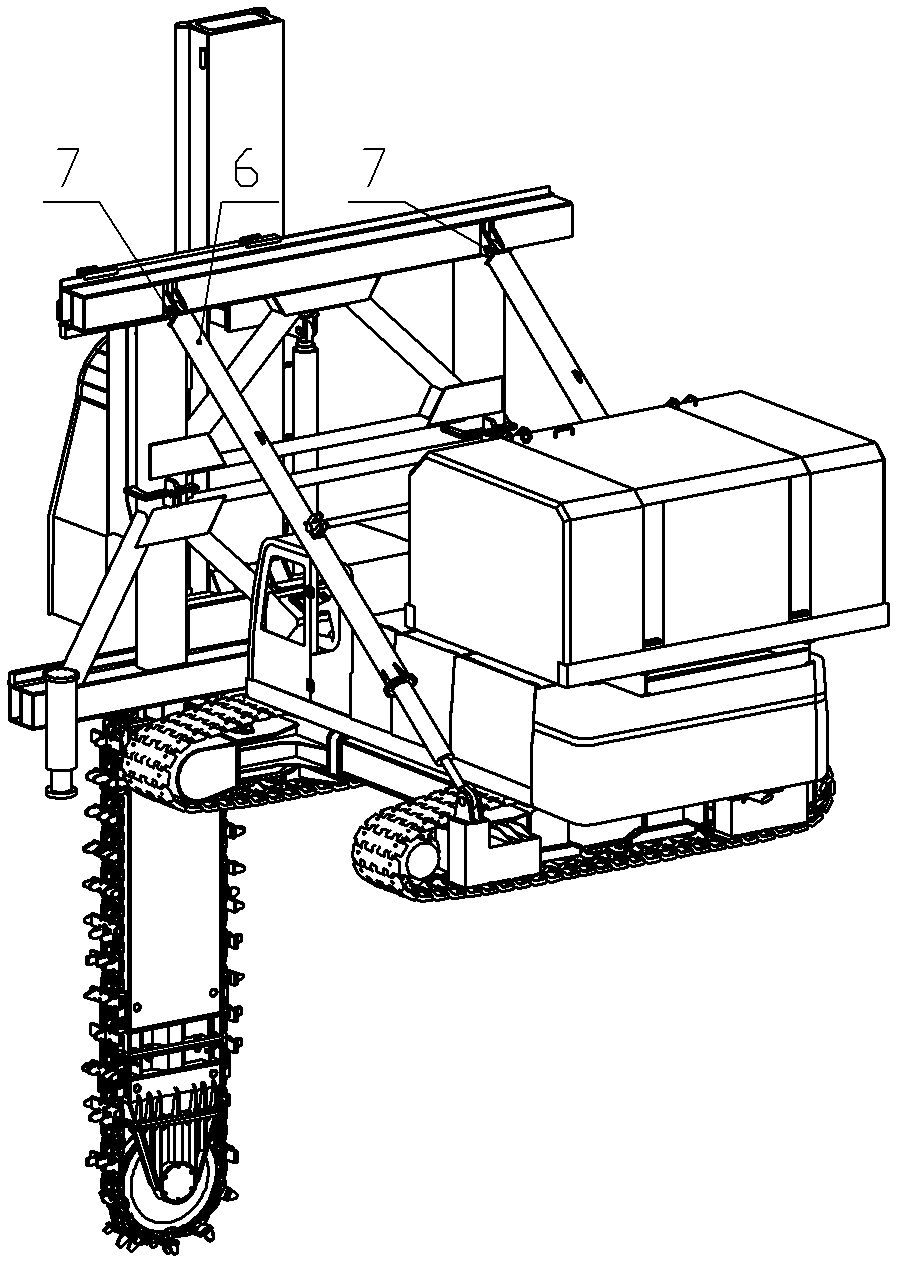

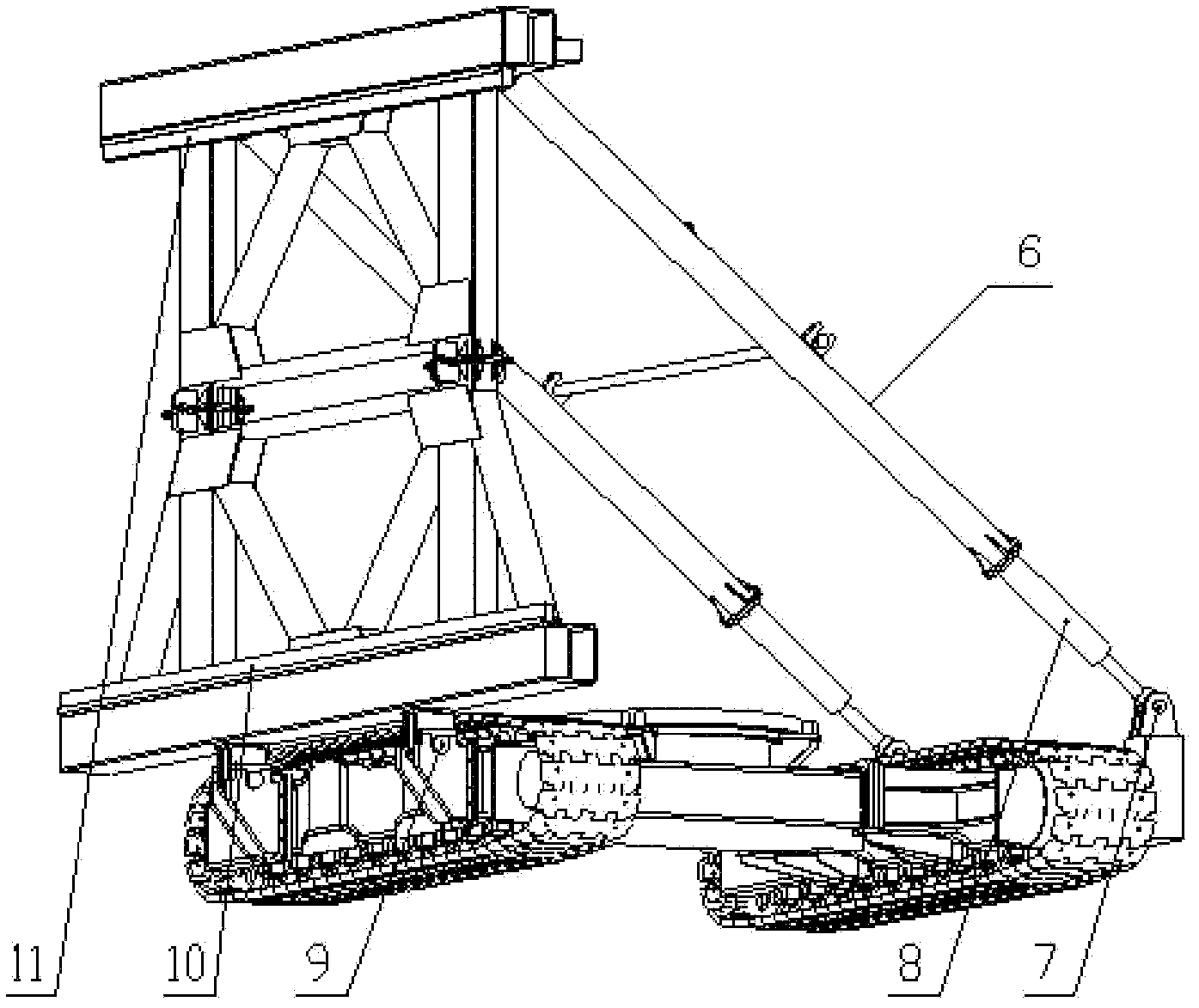

[0029] See Figure 1-Figure 7 , the chain-knife-type mixing pile wall-forming equipment is composed of a main machine 1, a crawler chassis assembly 2, a chain knife connecting frame 3, a synchronous grouting system 4, and a chain knife cutting box assembly 5; the main machine 1 is set on the chassis assembly 2 , the power unit and electro-hydraulic system are installed on the main engine 1 to provide power and control for the walking of the equipment and the rotary cutting of the chain knife; the whole machine can move along the direction of the wall through the chassis 2; one side of the chassis assembly 2 is connected through the front Bearing pin 9 is connected with chain knife connecting frame 3 bottoms, and the top of chain knife connecting frame 3 is connected with oblique stay rod 6, and oblique stay rod 6 is connected with the other side of chassis assembly 2 by adjusting oil cylinder 8 after connecting pin shaft 7, can Realize the angle adjustment in one direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com