Treatment system and method for consolidating soft soil foundation by utilizing industrial waste gas heat

A technology for soft soil foundation and industrial waste gas, which is applied in soil protection, infrastructure engineering, construction, etc. It can solve the problems of low-carbon environmental protection and construction efficiency gaps in processing devices, achieve significant low-carbon environmental protection effects, and accelerate carbonization and solidification , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

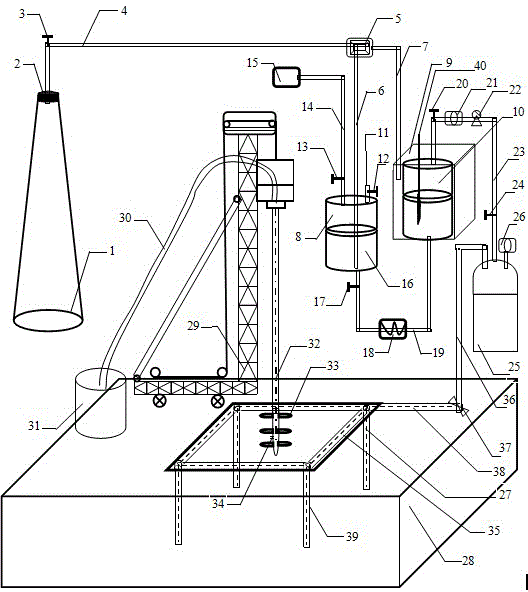

[0037] a. Use the anti-corrosion insulation pipe 4 to transfer the heat of the industrial waste gas after dust removal into the industrial waste gas thermal separation device 5, and the separated waste gas passes into the absorption chamber 8 through the anti-corrosion air guide pipe 6, and the separated heat is introduced through the anti-corrosion heat conduction pipe 7 heating box 9,

[0038] b. The reaction solution 16 added in the absorption chamber 8 is sodium hydroxide solution, close the exhaust valve B12, open the control valve A13, after excessive carbon dioxide gas and solution fully react to generate saturated sodium bicarbonate solution, close the control valve A13 and reduce Pressure valve 20, open control valve B17 and control valve C24, the exhaust gas will press the saturated sodium bicarbonate solution in the absorption chamber 8 into the decomposition chamber 10 through the condensation pipe 19, after the solution completely enters the decomposition chamber 1...

Embodiment 2

[0045] a. Use the anti-corrosion insulation pipe 4 to transfer the heat of the industrial waste gas after dust removal into the industrial waste gas thermal separation device 5, and the separated waste gas passes into the absorption chamber 8 through the anti-corrosion air guide pipe 6, and the separated heat is introduced through the anti-corrosion heat conduction pipe 7 heating box 9,

[0046]b. The reaction solution 16 added in the absorption chamber 8 is a sodium carbonate solution, close the exhaust valve B12, open the control valve A13, after excess carbon dioxide gas and the solution fully react to generate saturated sodium bicarbonate solution, close the control valve A13 and reduce pressure Valve 20, open the control valve B17 and control valve C24, the exhaust gas will press the saturated sodium bicarbonate solution in the absorption chamber 8 into the decomposition chamber 10 through the condensation pipe 19, after the solution completely enters the decomposition cha...

Embodiment 3

[0053] a. Use the anti-corrosion insulation pipe 4 to transfer the heat of the industrial waste gas after dust removal into the industrial waste gas thermal separation device 5, and the separated waste gas passes into the absorption chamber 8 through the anti-corrosion air guide pipe 6, and the separated heat is introduced through the anti-corrosion heat conduction pipe 7 heating box 9,

[0054] b. the reaction solution 16 added in the absorption chamber 8 is potassium hydroxide solution, close the exhaust valve B12, open the control valve A13, after excessive carbon dioxide gas and solution fully react to generate saturated potassium bicarbonate solution, close the control valve A13 and reduce Pressure valve 20, open control valve B17 and control valve C24, the exhaust gas will press the saturated potassium bicarbonate solution in the absorption chamber 8 into the decomposition chamber 10 through the condensation pipe 19, after the solution completely enters the decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com