Construction method of building anti-permeability channel using soil curing agent

A technology of soil curing agent and construction method, which is applied in the field of using soil curing agent to build anti-seepage channels, can solve the problems of insufficient asphalt material source, low early strength, and heavy masonry workload, etc., and achieve the improvement of canal system water utilization coefficient, High strength and anti-seepage performance, the effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: dry and hard solidified soil channel construction:

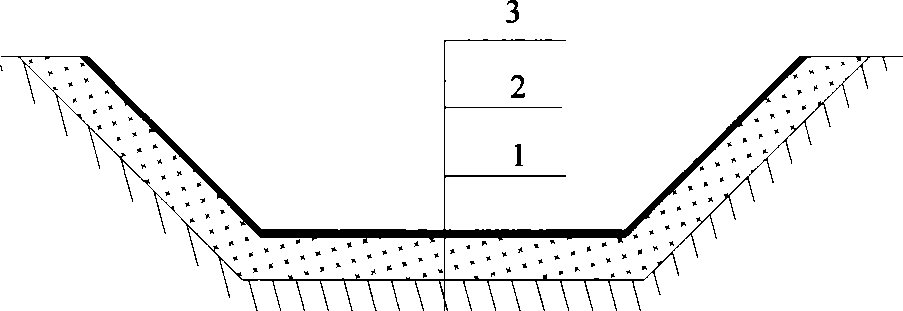

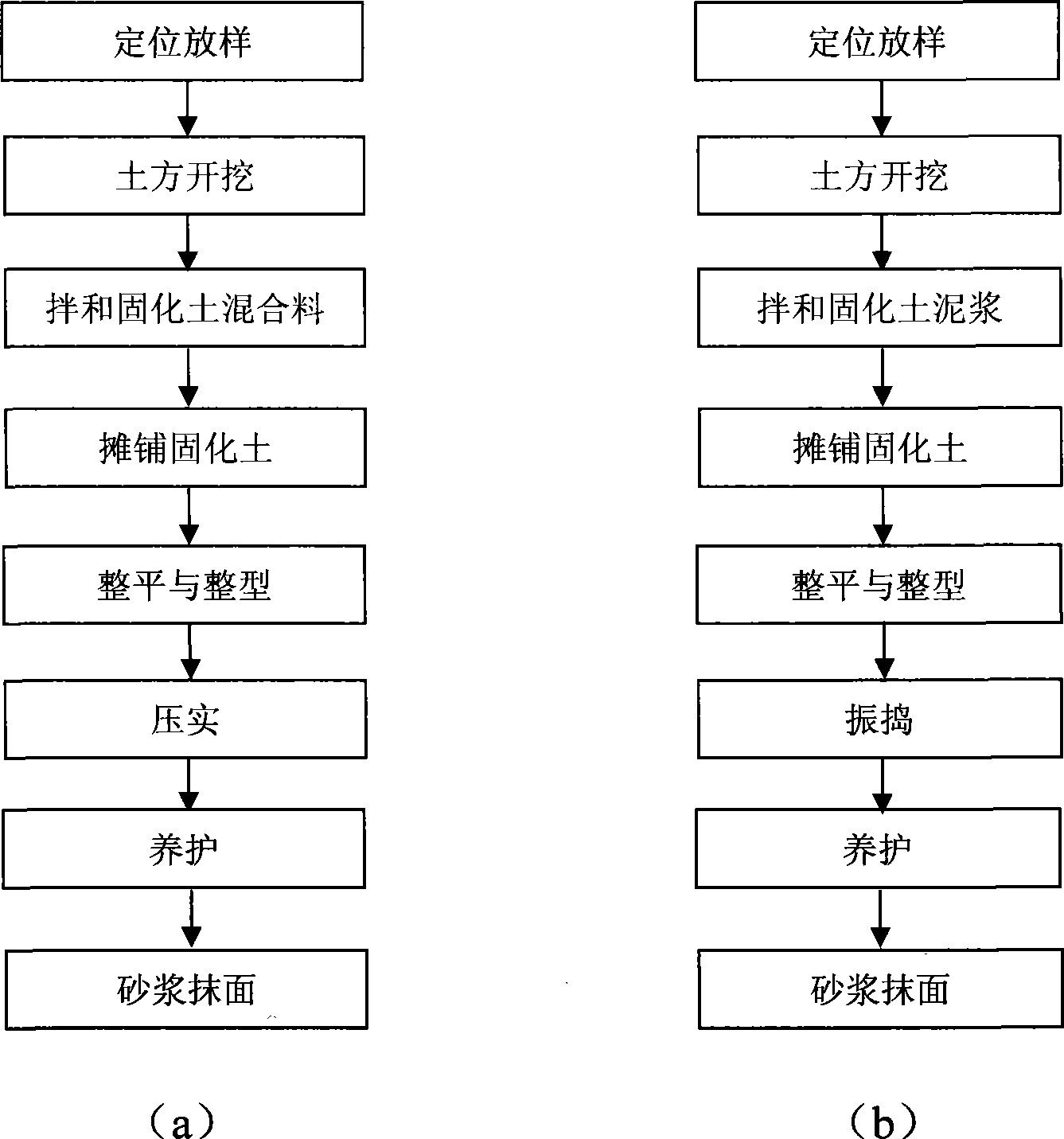

[0034] see figure 1 , image 3 (a), specifically including the following steps:

[0035] 1) Level the construction site, remove turf, tree roots, etc. According to the requirements of the design drawings, carry out on-site measurement and stakeout, the width of the canal bottom is 1.0m, the width of the top of the canal is 6.0m, and the depth of the canal is 1.5m, and the axis of the canal is determined. At a distance of 10m from one side of the canal, set a benchmark every 50m to ensure that the elevations of the canal bottom and top of each section meet the design requirements.

[0036] 2) Excavate the canal foundation with an excavator, level it out, fill it up manually and compact it with a rammer. The error of the channel base groove surface after compaction shall not exceed 30mm.

[0037] 3) Grinding the excavated soil material to make the particle size less than 10 mm, and then mixing with wa...

Embodiment 2

[0043] Embodiment 2: construction of plastic solidified soil channel:

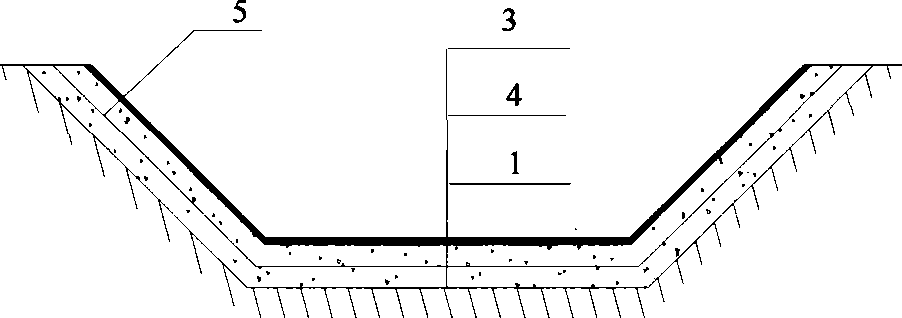

[0044] see figure 2 , image 3 (b), specifically including the following steps:

[0045] 1) Level the construction site, remove turf, tree roots, etc. According to the requirements of the design drawings, carry out on-site measurement and stakeout, the width of the canal bottom is 1.0m, the width of the top of the canal is 6.0m, and the depth of the canal is 1.5m, and the axis of the canal is determined. At a distance of 10m from one side of the canal, set a benchmark every 50m to ensure that the elevations of the canal bottom and top of each section meet the design requirements.

[0046] 2) Excavate the canal foundation with an excavator, level it out, fill it up manually and compact it with a rammer. The error of the channel base groove surface after compaction shall not exceed 30mm.

[0047] 3) Take a certain volume of excavated soil and pass it through a 10mm soil sieve. According to the ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com