Foundation pit water-sealing supporting method by using long spiral cement soil mixing structural steel pile

A technology of cement-soil mixing piles and cement-soil, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of large area occupied by supporting equipment, bulky and heavy equipment, and inconvenient entry and exit, so as to improve reliability and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

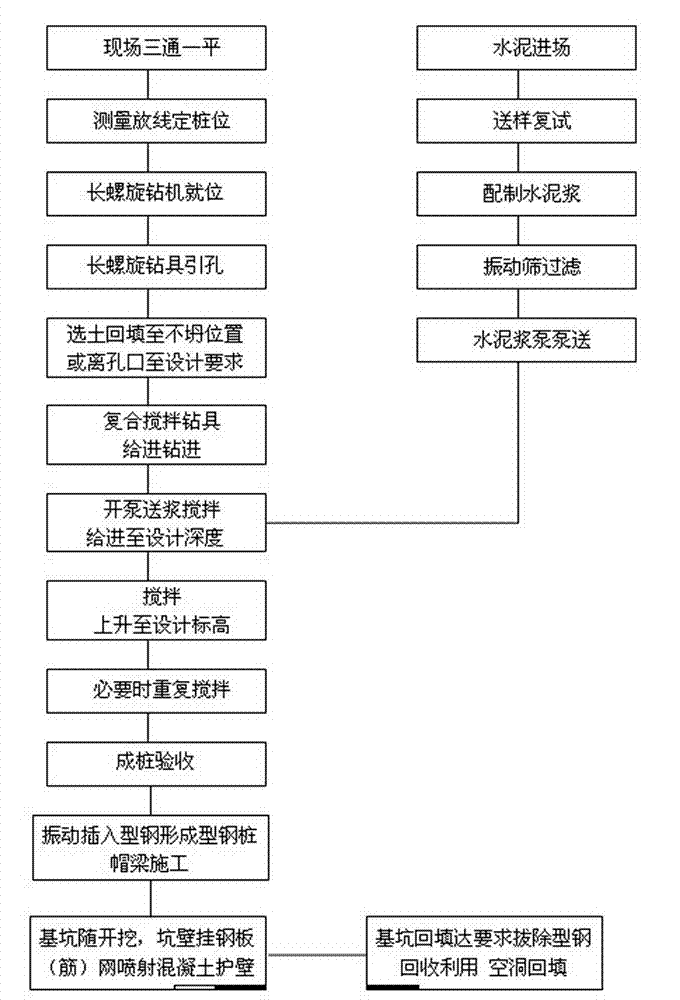

Method used

Image

Examples

specific Embodiment

[0043] 1. Project overview and engineering, hydrogeological conditions

[0044] 1.1 Project overview

[0045] The proposed expansion project of the Veteran Cadres Activity Center in Shunyi District, Beijing is located in the yard of the Veteran Cadres Activity Bureau in Shunyi District, Beijing. The main design this time is the foundation pit excavation and support plan for the expansion project of the Veteran Cadres Activity Center in Shunyi District, with a foundation depth of about 6.6m. The north side is 1m away from the fence, and the outside of the fence is the current road; the south side is 4m away from the existing 4-story old cadre activity center, and there are heating and water supply pipelines; the east side is 2m away from the fence, and the outside of the fence is a road green belt; the west side is 10m away from the fence , the site is used as a stockyard and processing site.

[0046] Engineering geological conditions

[0047] Typical formation: plain fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com