Bidirectional cement-soil mixing pile machine

A cement-soil mixing pile and frame technology, which is applied to sheet pile walls, earthwork drilling, drilling equipment, etc., can solve the problems of high power of dual motors, adding lubricating oil pumps, long transmission lines, etc., and achieves ease of use and maintenance , reduced power consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. The embodiment is only a detailed description of the technical solutions of the present invention, and does not constitute a limitation on the claims of the present invention.

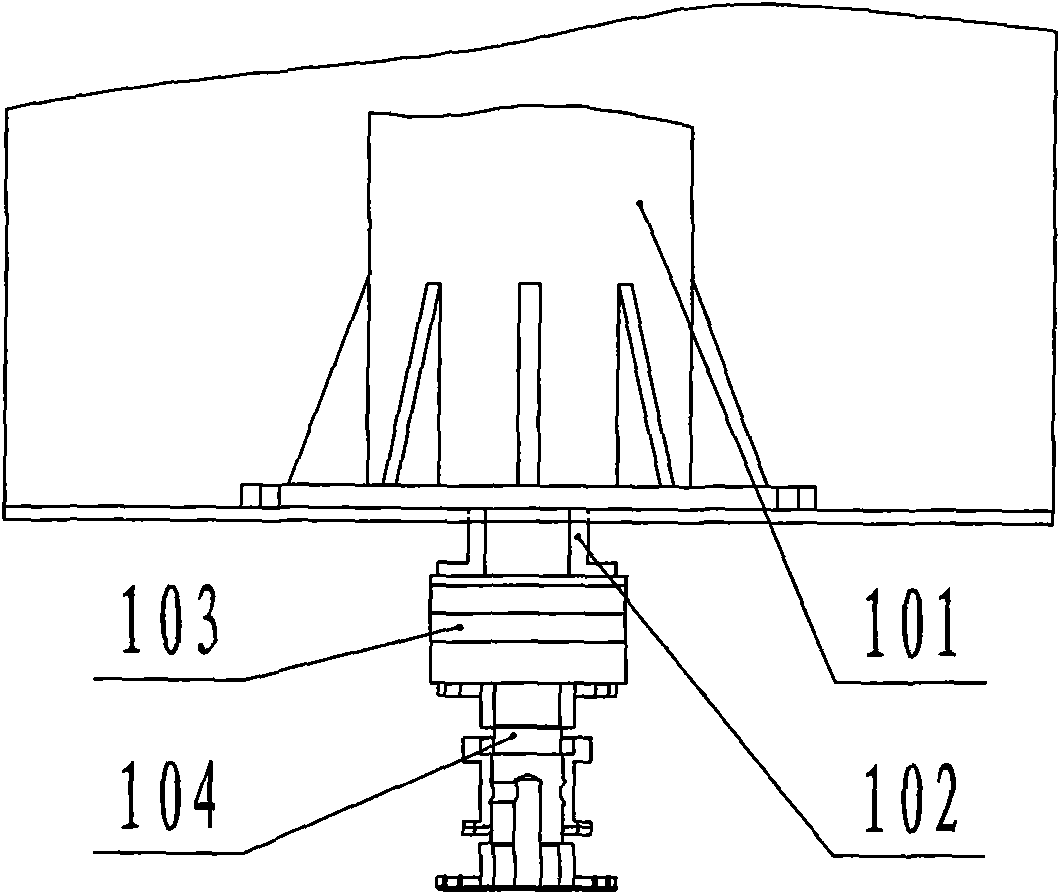

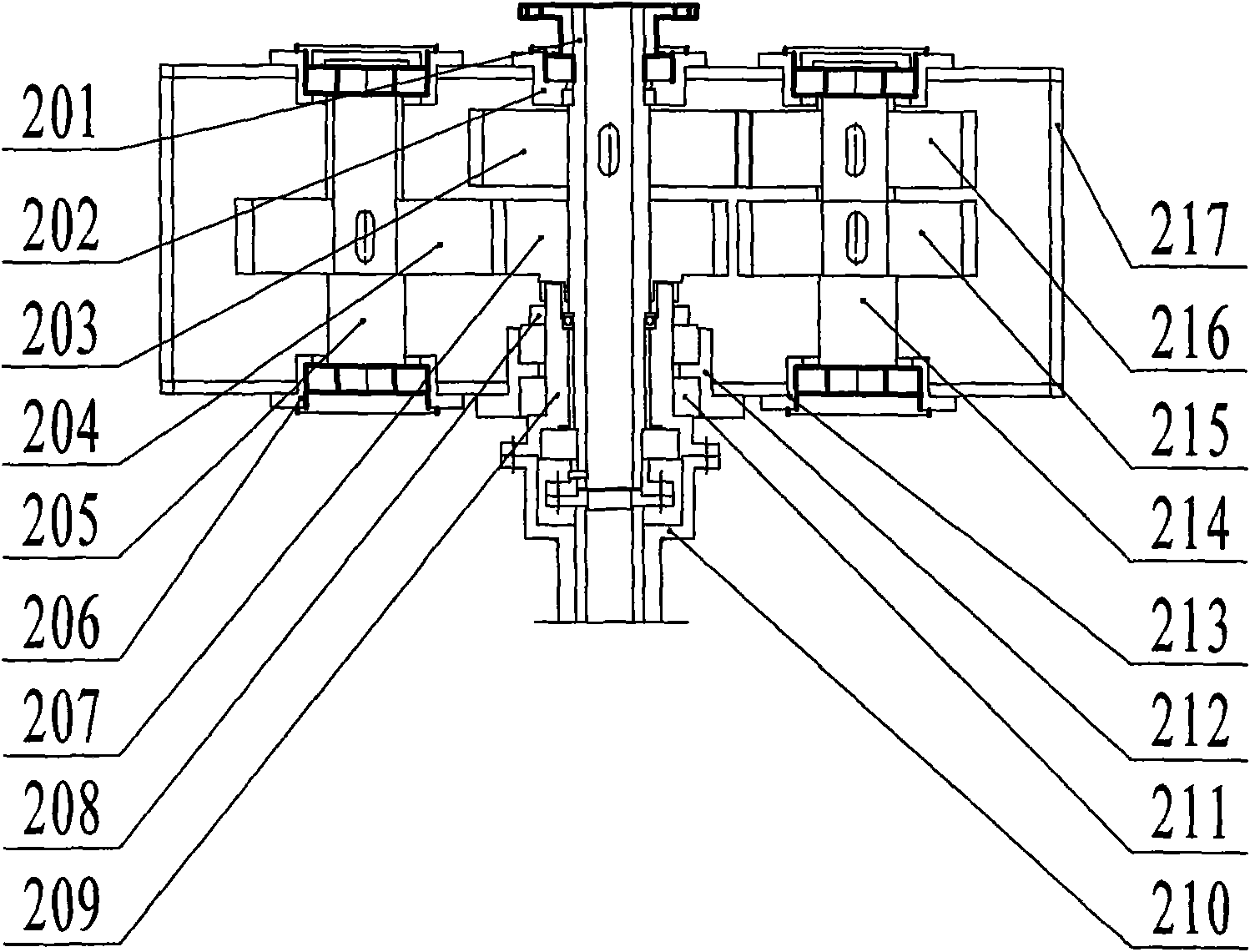

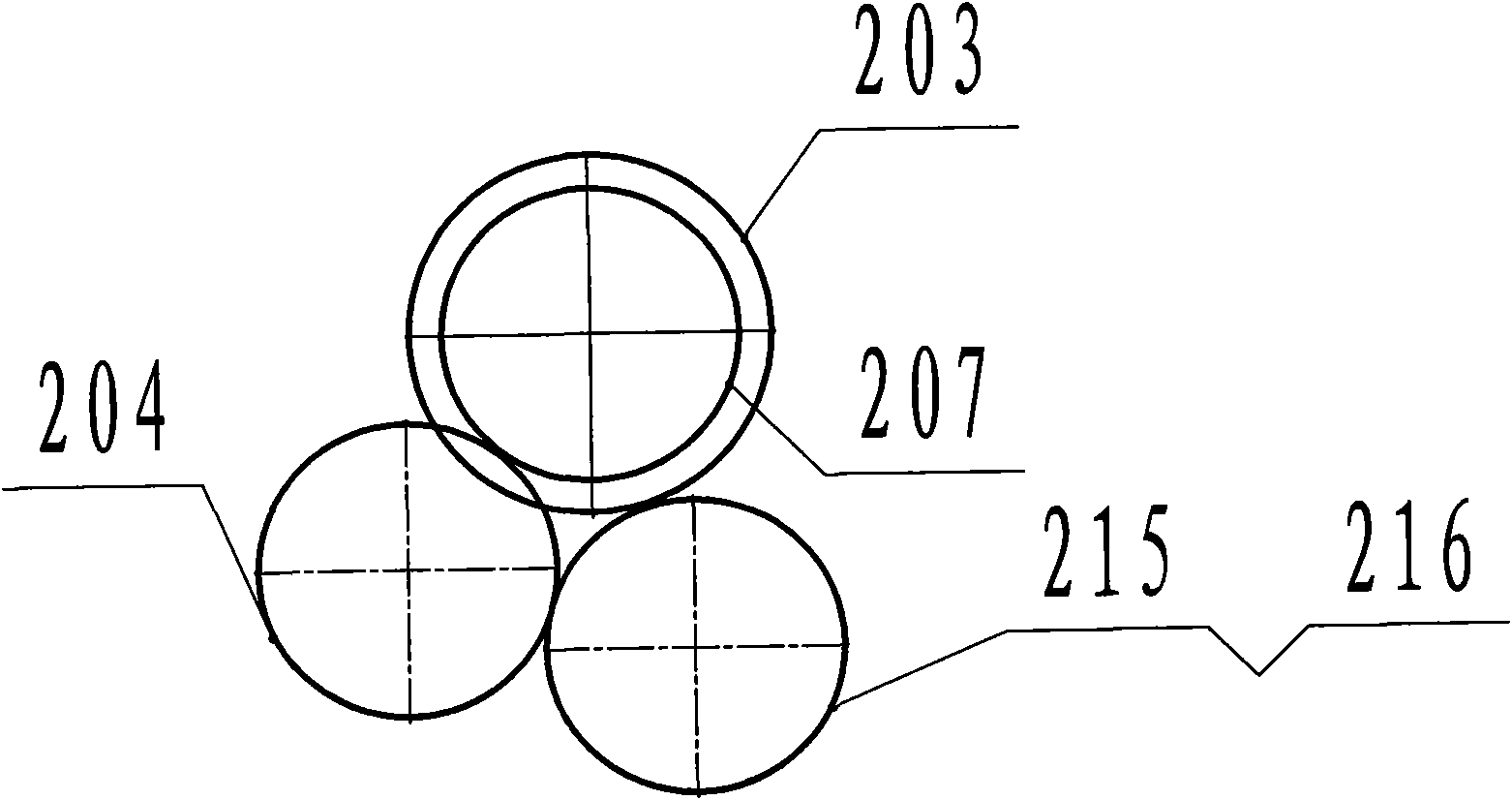

[0015] The two-way cement-soil mixing pile driver of this design (hereinafter referred to as the pile driver, see Figure 1-6 ), including power source 1, transmission mechanism 2, drill bit body 3 and frame 4 four parts, the power source 1 of pile driver of the present invention is hoisted on the frame 4 by wire rope as in the prior art, is characterized in that described The power source 1 includes a single motor and a reducer 101, a motor flange 102, a coupling 103, and a grouting joint 104 that are mechanically connected in sequence. The single motor and the reducer 101 are hoisted on the frame 4; specifically, the grouting joint 104 The upper end face of the shaft coupling 103 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com