Five-axis cement-soil mixing pile device and construction method

A cement-soil mixing pile and cement slurry technology, which is applied in earth drilling, drilling equipment and methods, excavation, etc., can solve the problems of insufficient starting power, many overlapping cold joints, and low work efficiency, and achieve the goal of increasing lifting capacity Ability, good safety performance, and increased efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

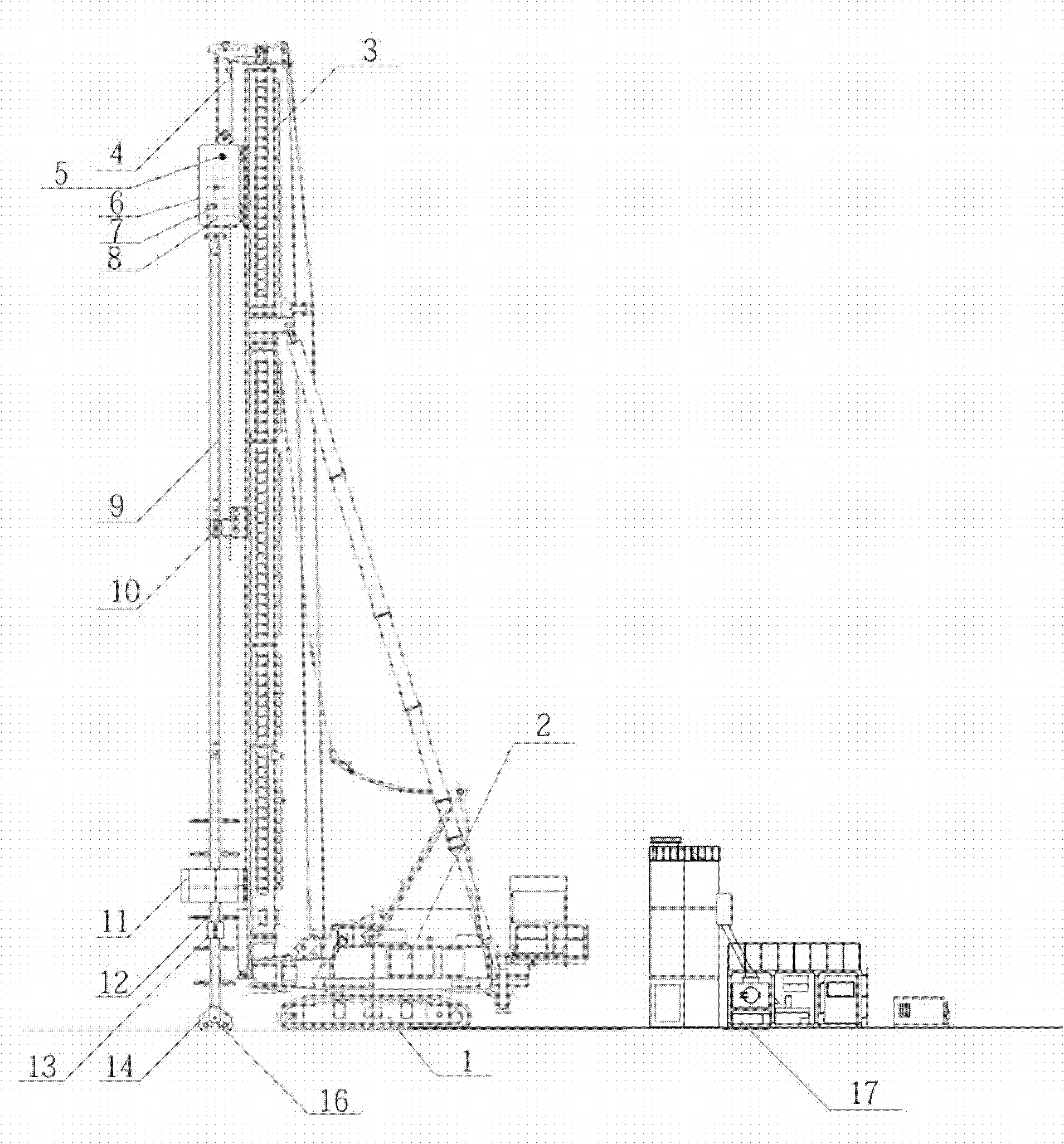

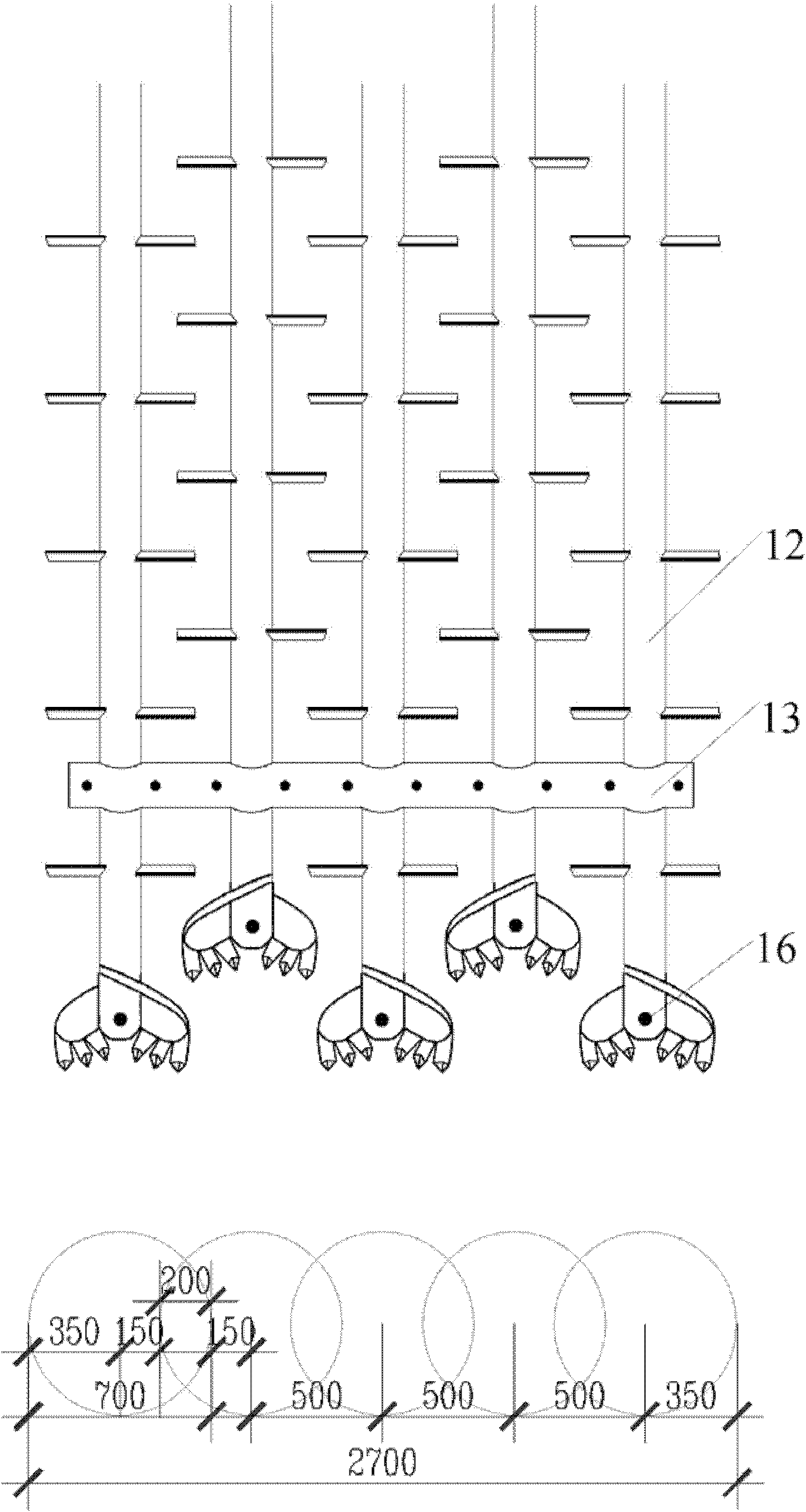

[0044] Such as Figure 1~2 As shown, a five-axis cement-soil mixing pile device includes a crawler-type and walking-type main engine 1, a winch 2, a guide rod 3, a steel wire rope 4, a slurry inlet 5, a power head 6, a gearbox 7, and a reducer 8 , drill rod 9, intermediate support frame 10, lower support frame 11, winged drill rod 12, hoop 13, multifunctional drill bit 14, spraying port 16, and the winch 2 and guide rod 3 are fixed on the main engine 1, The power head 6 is connected to the pulley at the top of the guide rod 3 through the wire rope 4, and the wire rope 4 drives the power head 6 to go up and down. The middle part of the rod 9 is provided with an intermediate support frame 10, and the lower part is provided with a lower support frame 11. The lower end of each drill rod 9 is connected with a winged drill rod 12. The winged drill rod 12 is provided with a hoop 13, and the winged drill The lower end of the rod 12 is threadedly connected to a multifunctional drill b...

Embodiment 2

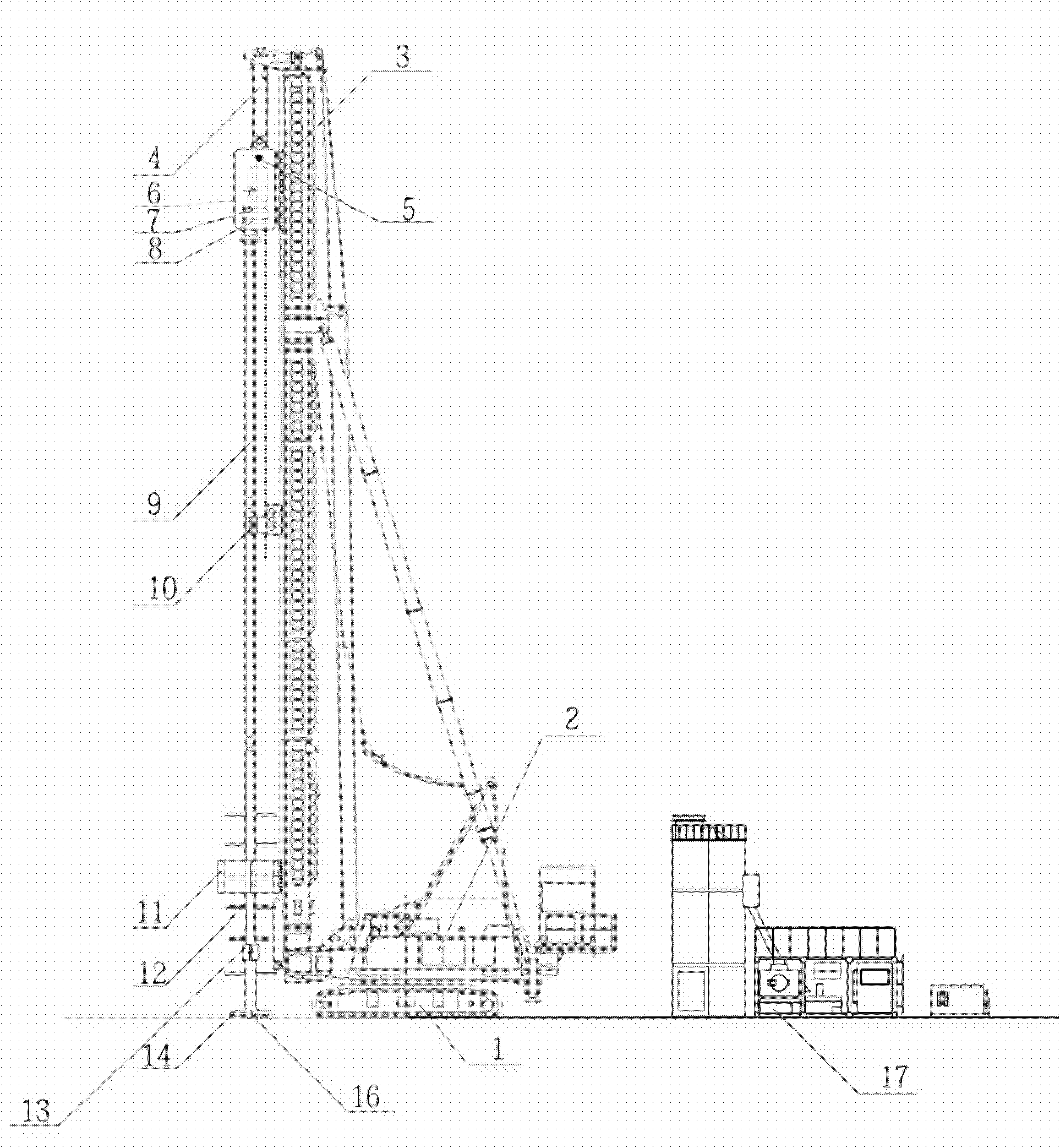

[0059] Such as Figure 3-4 As shown, a five-axis cement-soil mixing pile device, the multi-functional drill bit 13 is a rake-type multi-functional drill bit, and is connected to the winged drill rod 12 through buckles. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com