Six-axis cement soil mixing pile

A technology for cement-soil mixing piles and cement-soil mixing walls, which is applied to sheet pile walls, buildings, infrastructure engineering, etc. The effect of reducing labor and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

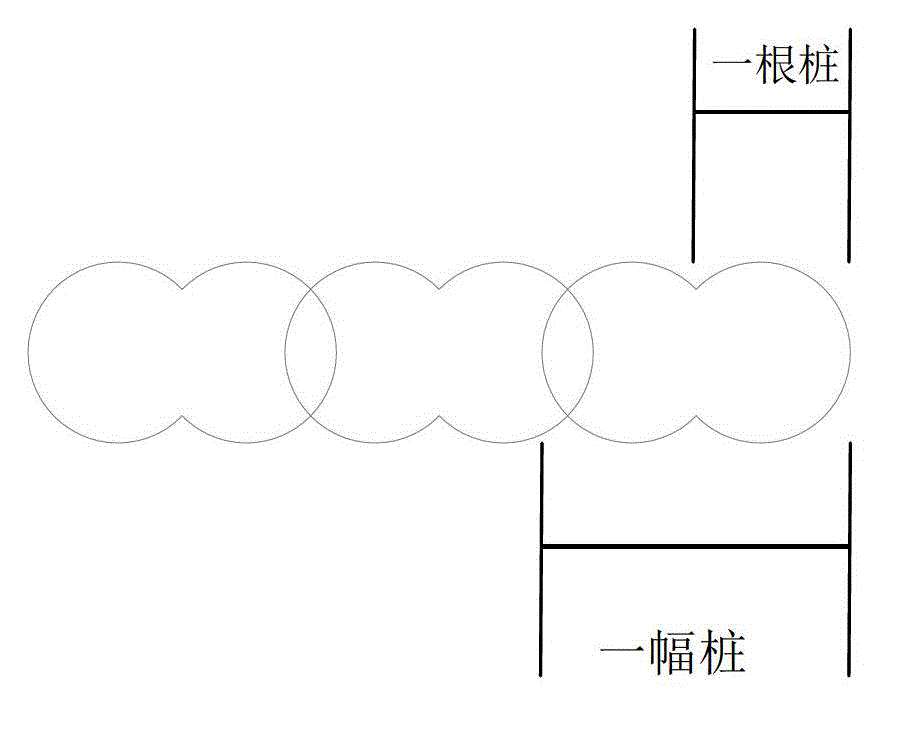

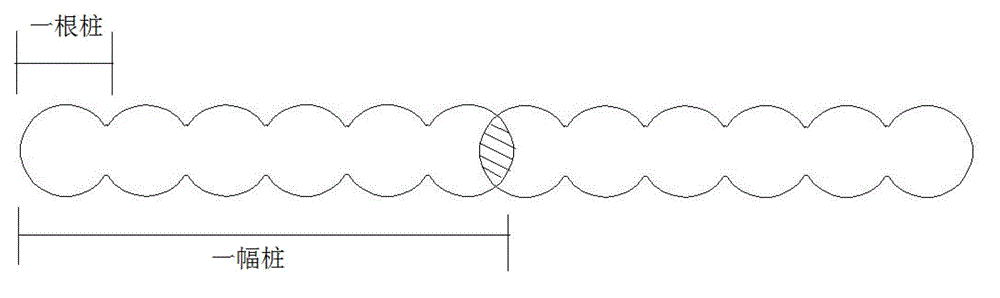

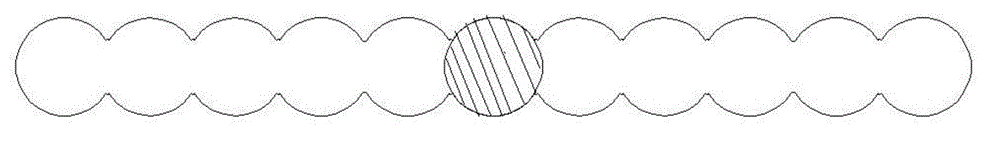

[0024] Six-axis cement-soil mixing pile, the cement-soil mixing pile is formed by mixing soil and cement slurry, a mixing wall is composed of multiple cement-soil mixing piles that overlap each other vertically, and multiple cement-soil mixing walls overlap each other to form a longer Each cement-soil mixing wall consists of six vertical cement-soil mixing piles. The six cement-soil mixing piles are formed at the same time. The six cement-soil mixing piles are on the same vertical surface, and the adjacent piles are built on each other. Connected; adjacent cement-soil mixing walls overlap each other.

[0025] First, six cement-soil mixing piles are formed to form a continuous cement-soil mixing wall, and multiple sets of cement-soil mixing walls f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com