Cold plant-mixed regenerated asphalt foaming device

A foaming device and cold regeneration technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of high consumption of pavement materials and energy, unreasonable utilization of old materials, etc., to achieve simple debugging, high foaming efficiency, and accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

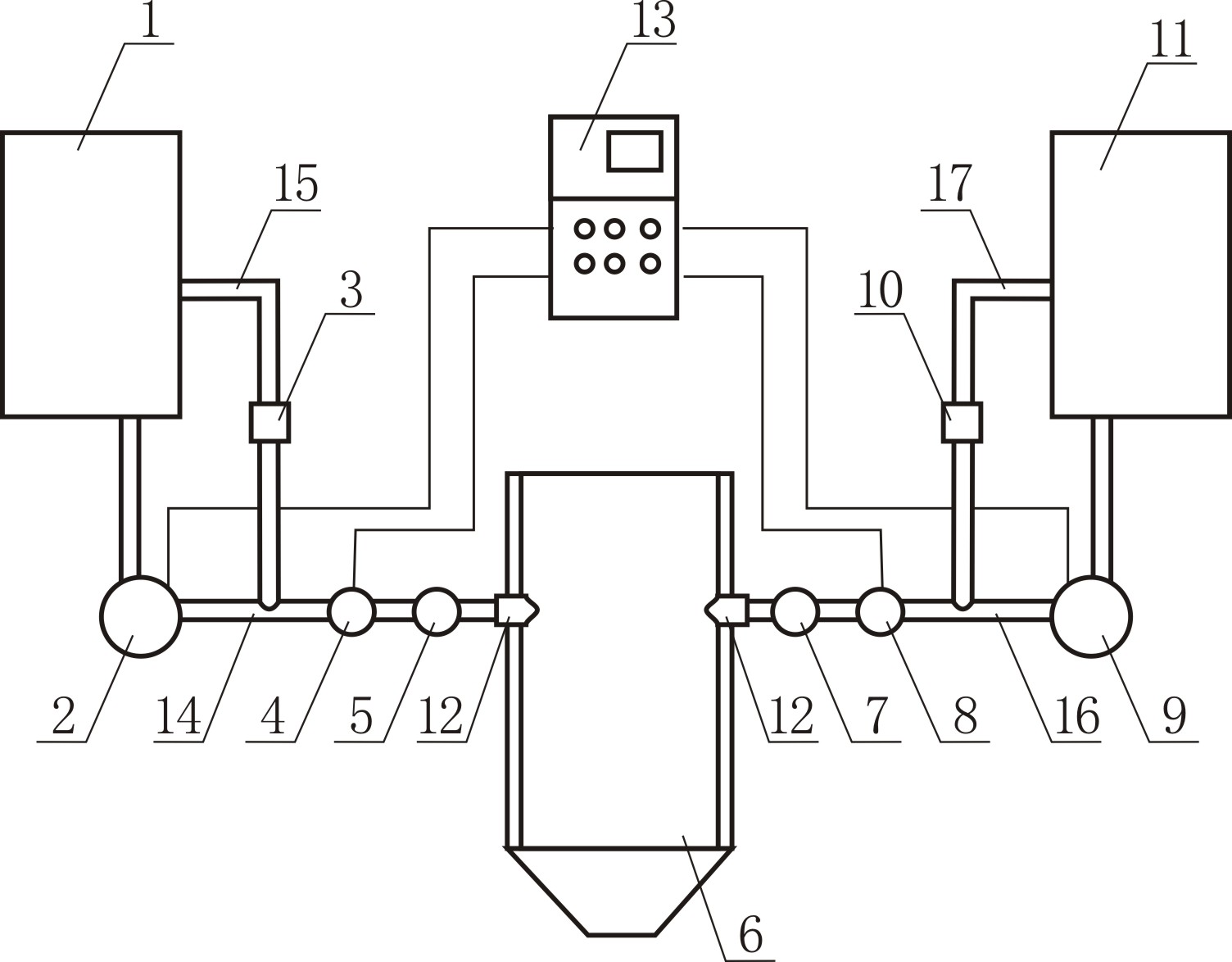

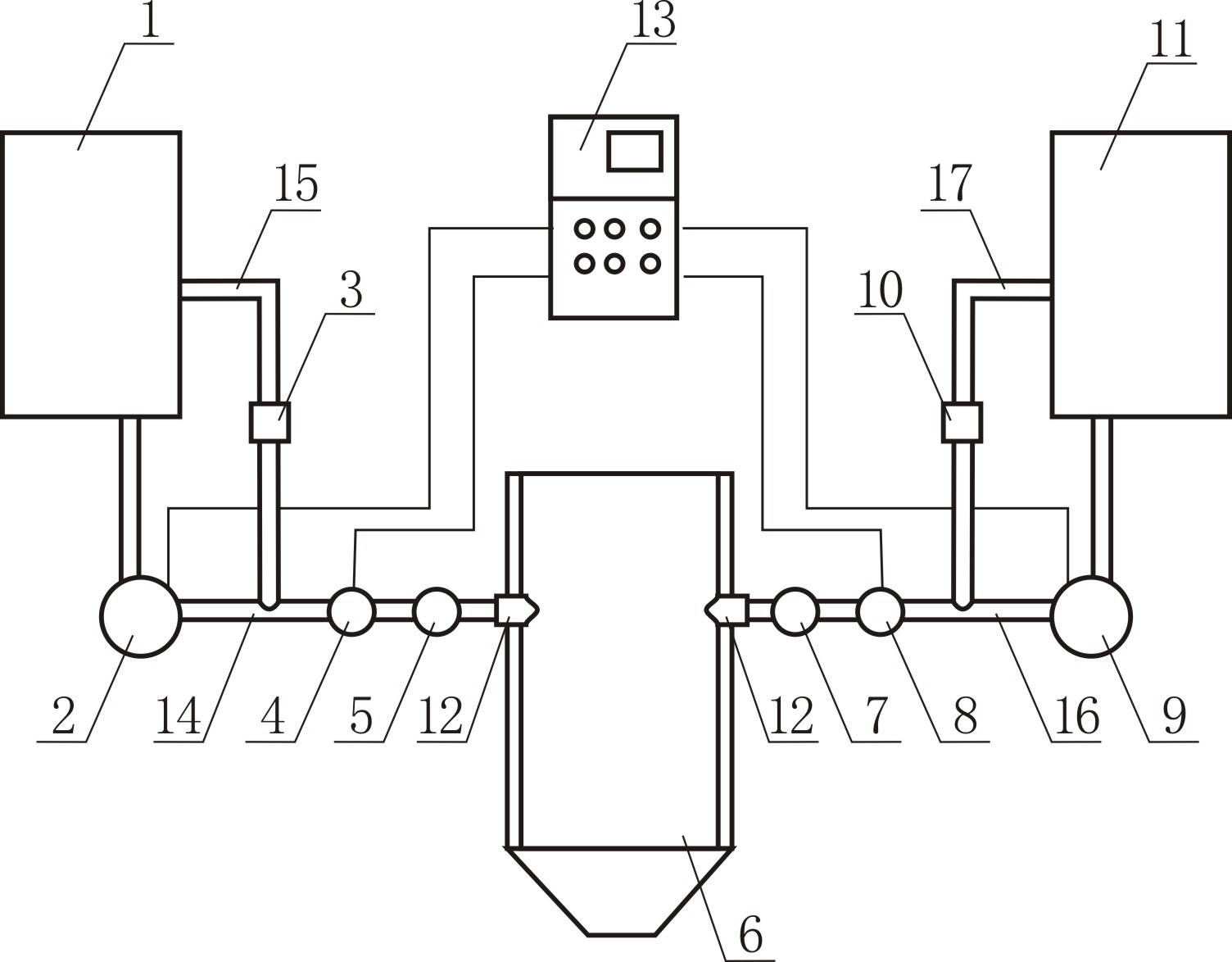

[0015] Such as figure 1 As shown, a factory-mixed cold recycled asphalt foaming device includes a foaming container 6, a PVC water storage tank 1, an asphalt heating storage tank 11 and two atomizing nozzles 12, and the two atomizing nozzles 12 are located at the foaming The two sides of the container 6 correspond to each other. After fully analyzing the principle and working mechanism of asphalt foaming, atomized asphalt and atomized water are selected for foaming in a horizontal 180°C hedge; one side of the foaming container 6 is set There is a controller 13; the PVC water storage tank 1 is connected to one of the atomizing nozzles 12 through a water delivery pipe 14, and the water delivery pipe 14 is provided with a plunger type speed regulating pump 2, a water flow meter 4, and a water pressure gauge 5 and a water pressure regulating return pipe 15, the water pressure regulating return pipe 15 is provided with a water pressure regulating valve 3, and the water flowmeter 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com