Novel cement soil composite mixing pile and pile formation method thereof

A technology of cement-soil mixing pile and mixing pile, which is applied to sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low pile strength and poor bearing capacity of pile foundation, and achieve good pile quality and pile foundation bearing capacity. High force, effect of changing material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

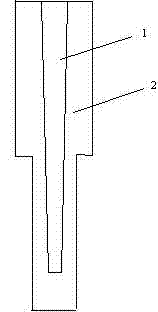

[0029] The new cement-soil composite mixing pile is composed of a variable-section cement-soil mixing pile and a square-edged reinforced concrete core pile. The small section of the core pile is inserted into the mixing pile along the center of the mixing pile section and closely matched with the mixing pile. The upper section of the cement-soil mixing pile is larger than the lower section, the total length of the pile is 12m, the diameter of the upper mixing pile is 700mm, and the length is 4m, and the diameter of the lower mixing pile is 500mm, and the length is 8m.

[0030] Among them, the variable cross-section modified cement-soil mixing pile is formed by uniformly mixing the undisturbed soil of the soft ground and the cement slurry injected with additives. The square-shaped reinforced concrete core pile is prefabricated by steel bars and concrete. The square side length of the upper section is 300mm, and the square side length of the lower section is 200mm. The length of ...

Embodiment 2

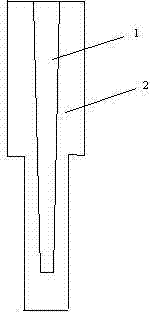

[0039] The new cement-soil composite mixing pile is composed of a variable-section cement-soil mixing pile and a square-edged reinforced concrete core pile. The small section of the core pile is inserted into the mixing pile along the center of the mixing pile section and closely matched with the mixing pile. The upper section of the cement-soil mixing pile is larger than the lower section, the total length of the pile is 18m, the diameter of the upper section of the mixing pile is 700mm, and the length is 9m, and the diameter of the lower section of the mixing pile is 500mm, and the length is 9m.

[0040]The variable cross-section modified cement-soil mixing pile is formed by uniformly mixing the undisturbed soil of the soft ground and the cement slurry injected with additives. The square-shaped reinforced concrete core pile is prefabricated by steel bars and concrete. The square side at the upper end is 350mm long, and the square side at the lower end is 150mm long. The core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com