Cement-soil mixing wall former

A cement-soil mixing and wall-forming machine technology, which is applied to sheet pile walls, earthwork drilling, water conservancy projects, etc., and can solve problems such as small thickness and unsatisfactory anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

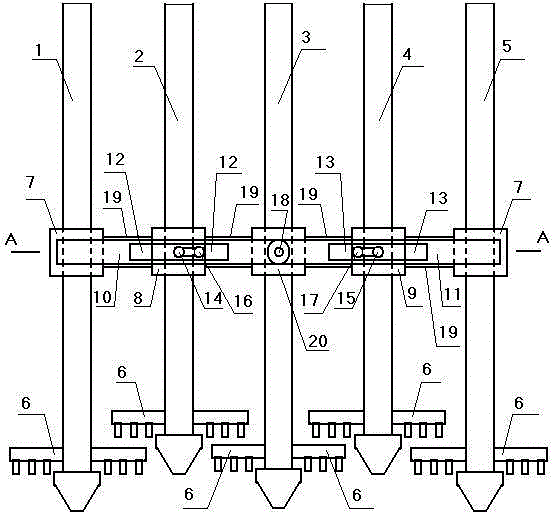

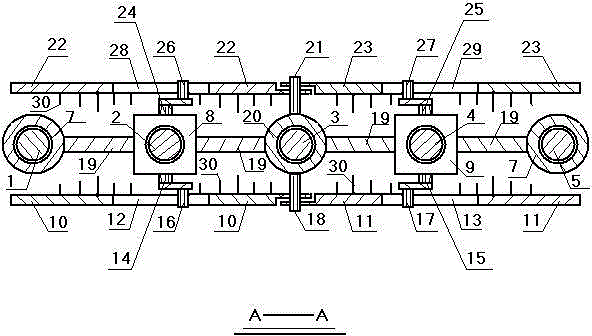

[0012] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment drilling rod ① 1, drilling rod ② 2, drilling rod ③ 3, drilling rod ④ 4, drilling rod ⑤ 5 lower ends are respectively provided with a drill bit 6, and drilling rod ① bottom is provided with a steel pipe Set ①7, the lower part of the drill pipe ② is provided with a drive box ①8, the lower part of the drill pipe ③ is provided with a steel pipe sleeve ②20, the lower part of the drill pipe ④ is provided with a drive box ②9, the lower part of the drill pipe ⑤ is provided with a steel pipe sleeve ①, the drill pipe ① The steel pipe sleeve ① and the drive box ① on the top, the drive box ① and the steel pipe sleeve ②, the steel pipe sleeve ② and the drive box ②, the steel pipe sleeve ① on the drive box ② and the drill pipe ⑤ are all fixed together with steel plates 19, and the front side of the drive box ① There is a crankshaft ①14, the crankpin ①16 of the crankshaft ① is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com