Extraction and mixing blender

A blender and extraction technology, applied in mixers, blender accessories, mixing methods, etc., can solve problems such as low extraction rate, difficulty in controlling suction, and poor oil-water mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

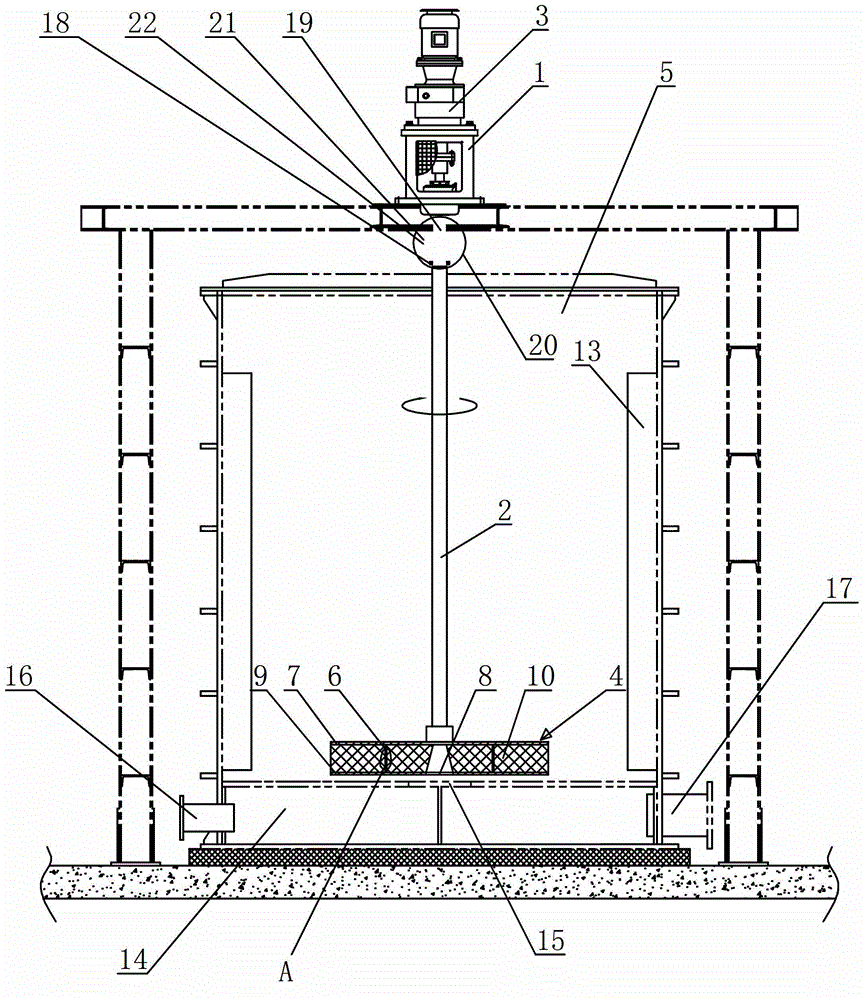

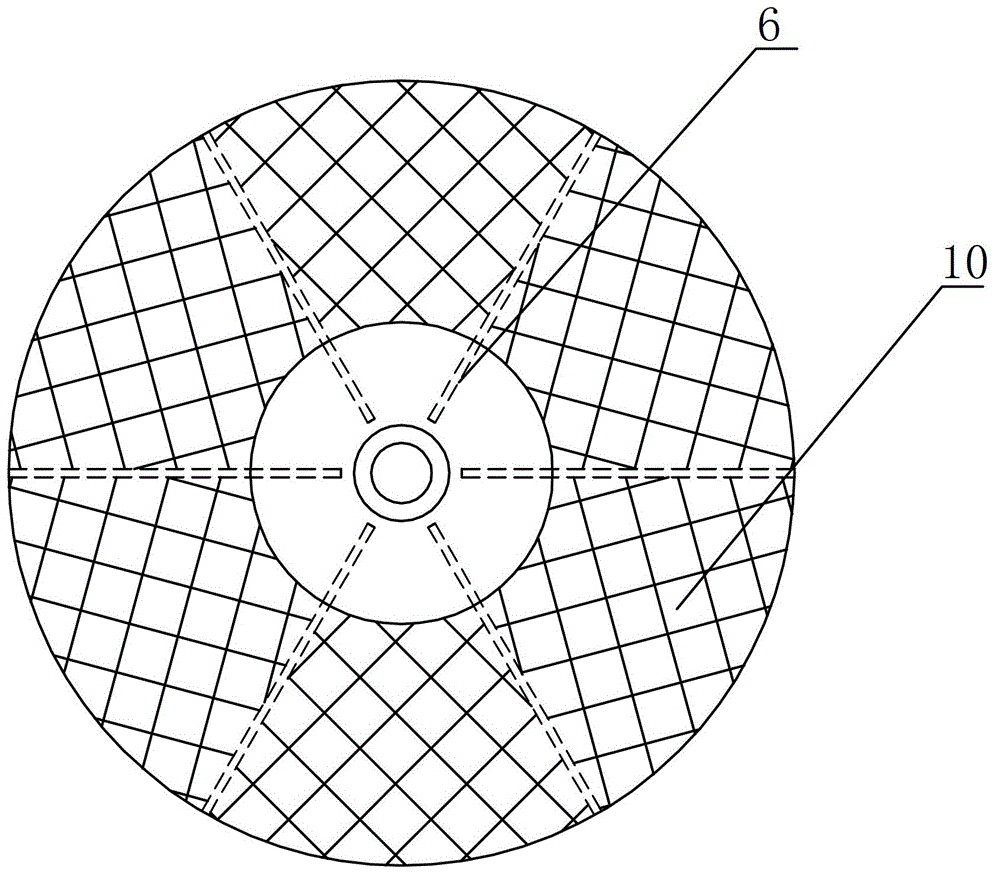

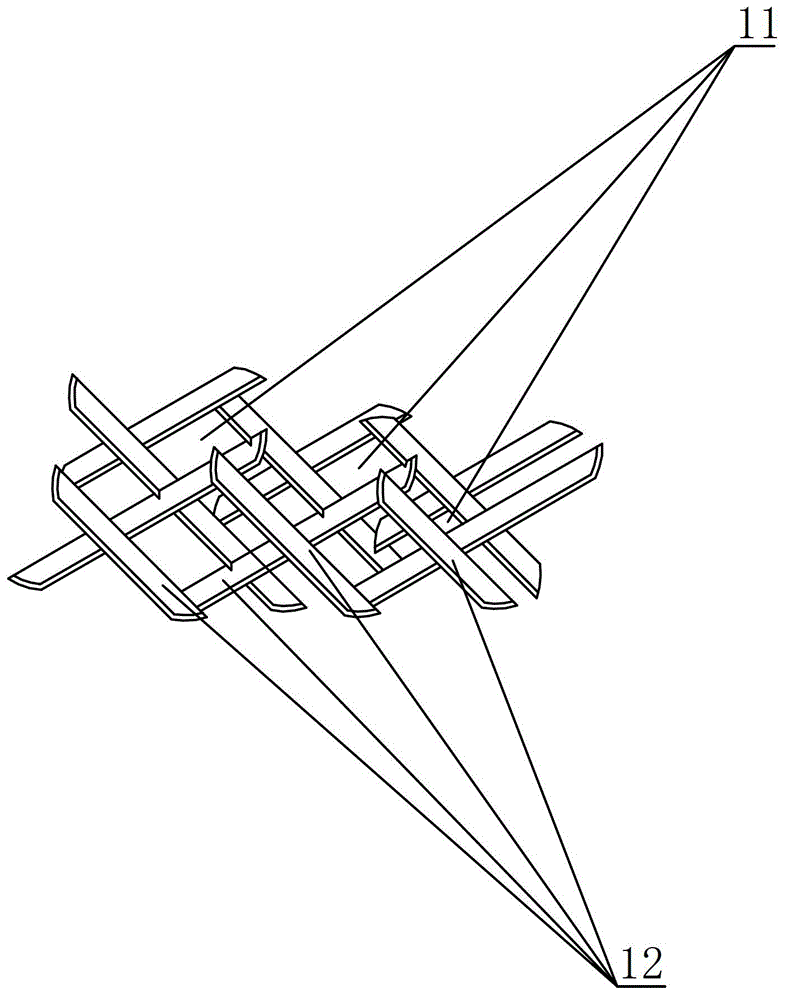

[0014] see figure 1 , an extraction mixing mixer, comprising a frame 1 and a stirring shaft 2, one end of the stirring shaft 2 is connected to a drive mechanism 3, the other end of the stirring shaft 2 is connected to a stirrer 4 and arranged in a stirring container 5, and the stirrer 4 is provided with Radial blade 6, the top of blade 6 is provided with upper cover plate 7, the bottom of blade 6 is provided with the lower cover plate 9 that the center is fluid suction port 8, is provided with for radial direction between upper cover plate 7 and lower cover plate 9. The mixing element 10 that passes and mixes the fluids. The mixing element 10 is provided with several fluid passing holes 11 for radially passing the fluid.

[0015] Further definition for the mixing element: the mixing element 10 is a group of net plates surrounded by the outer circle of the fluid flow direction hole 8, the mesh of the net plate is a fluid passing hole 11, and the mixing element 10 adopts several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com