System for treating BHP effluent

A waste liquid treatment system and waste liquid technology, applied in the direction of special treatment targets, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as explosions and potential safety hazards, and achieve the reduction of potential safety hazards, stable and safe operation, and purification effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

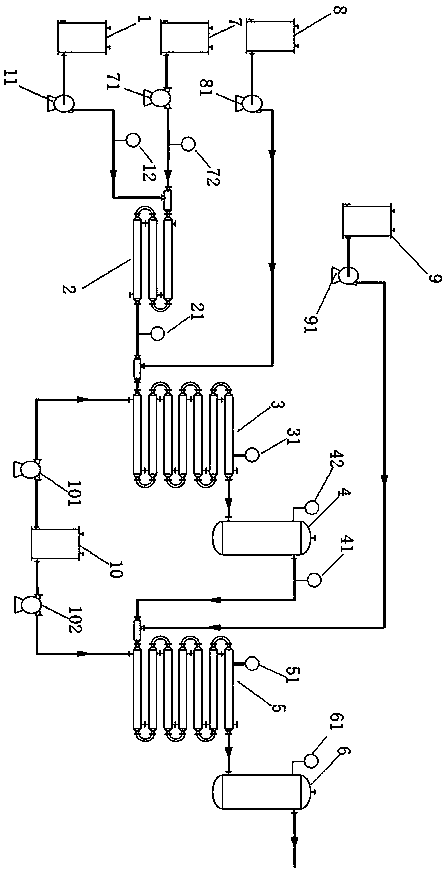

[0021] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0022] Such as figure 1 As shown, a BHP waste liquid treatment system includes a BHP waste liquid storage tank 1, a BHP waste liquid diluter 2, a primary reactor 3, a primary stabilization tank 4, a secondary reactor 5, and a secondary stabilization tank 6, The components are connected sequentially by pipes. The BHP waste liquid diluter 2 is also connected with the dilution water storage tank 7 through pipelines; the primary reactor 3 is connected with the concentrated hydrochloric acid storage tank 8 through pipelines; the secondary reactor 5 is also connected with the dilute hydrochloric acid storage tank 9 through pipelines .

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com