Particle material batch mixing device

A granular material and mixed batch technology, which is applied in the direction of mixers, mixing methods, transportation and packaging, etc., can solve the problems of inability to meet the needs of large-scale production, low production capacity and mixed batch efficiency, and critical accidents, so as to avoid a large amount of materials Aggregation, efficiency improvement, avoiding the effect of squeezing each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

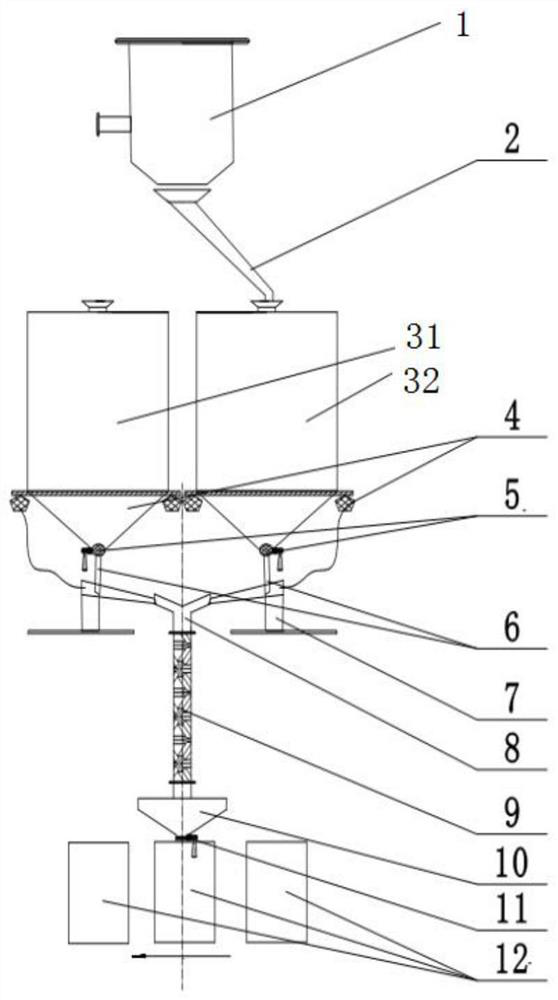

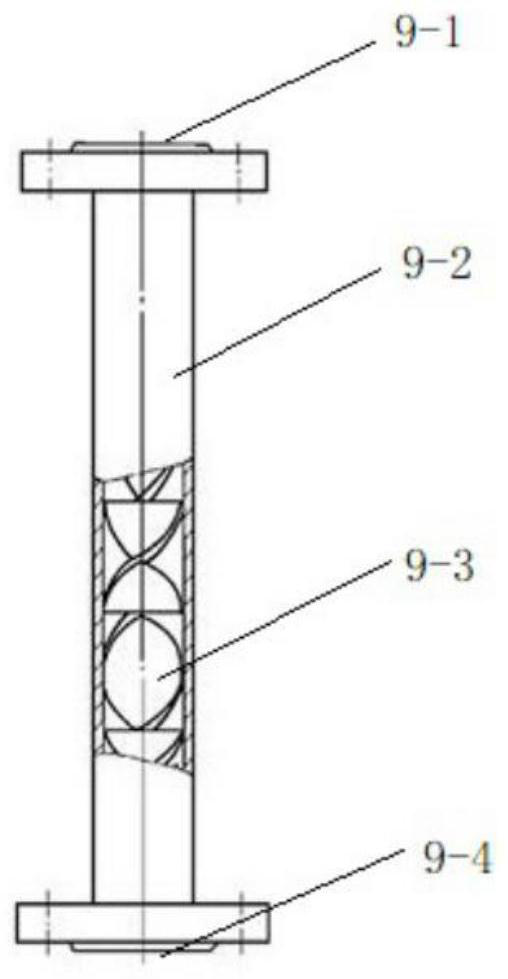

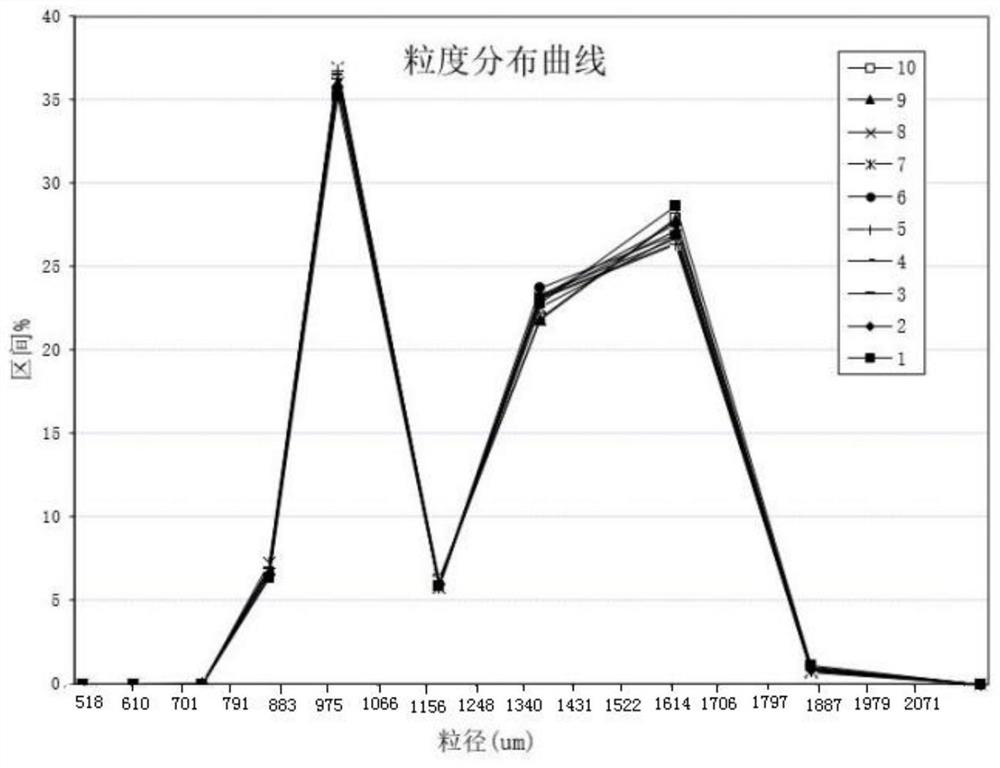

[0048]The granular material mixing device provided by the present invention is used for multiple batches of granular materials, especially for materials with better particle fluidity (such as spherical particles), and moves from top to bottom under the action of gravity through the static mixer 9 The mixing unit in the static mixer 9 is divided and merged multiple times, so that multiple batches of granular materials are continuousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com