A coal slime water energy-saving heating device

A heating device and coal slime water technology, applied in solid separation, chemical instruments and methods, flotation, etc., can solve the problems of high coal washing cost, large amount of flocculant added, waste heat of air compressor, etc. The effect of saving usage and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

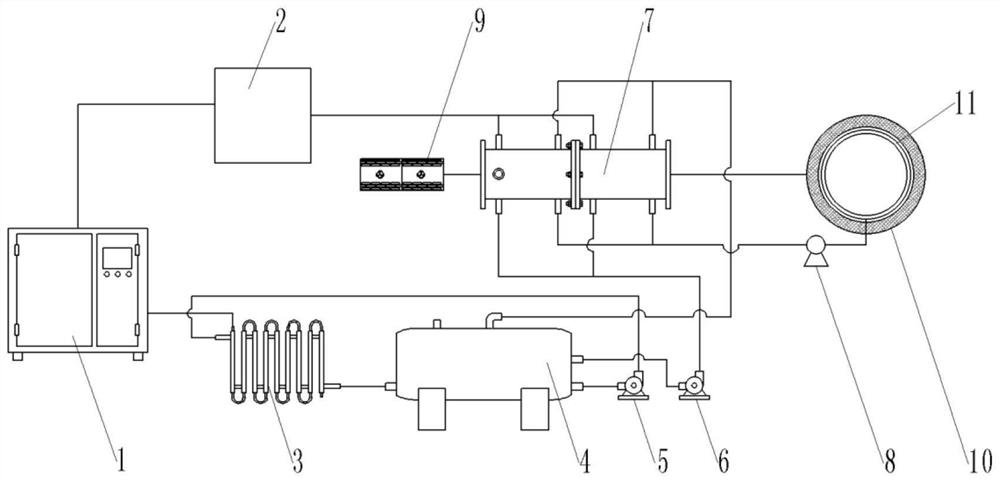

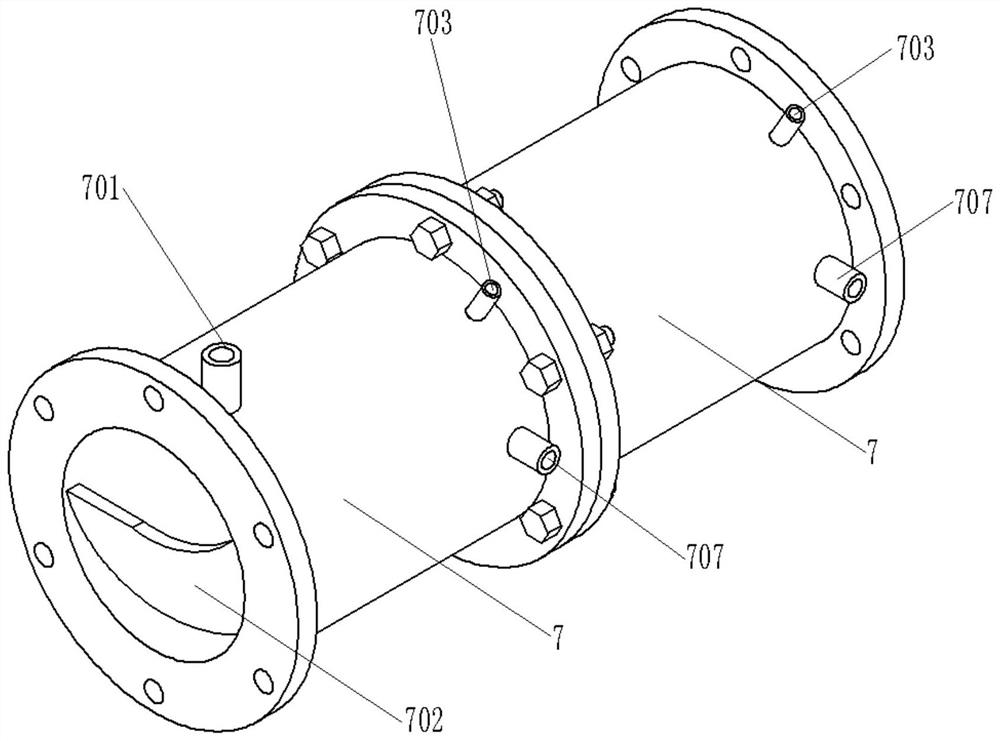

[0034] Example 1: Please refer to figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a coal slime water energy-saving heating device, comprising an air compressor 1, a hot gas chamber 2, a heat exchanger 3, a water storage tank 4, a first water pump 5, a second water pump 6, a heating mixing pipe 7 and a blower fan 8; by flotation The coal slime water discharged by machine 9 flows into the thickening tank 10 through the heating mixing pipe 7, and the heating mixing pipe 7 is provided with a 180 ° twisted spiral blade 702, and the outer diameter of the spiral blade 702 is slightly smaller than the inner diameter of the heating mixing pipe 7, and the spiral blade 702 is a hollow structure, and the two ends of the helical blade 702 are respectively connected with a first pipe joint 703 communicating with the hollow part of the helical blade 702, and the first pipe joint 703 passes through the pipe wall of the heating mixing pipe 7; the heatin...

Embodiment 2

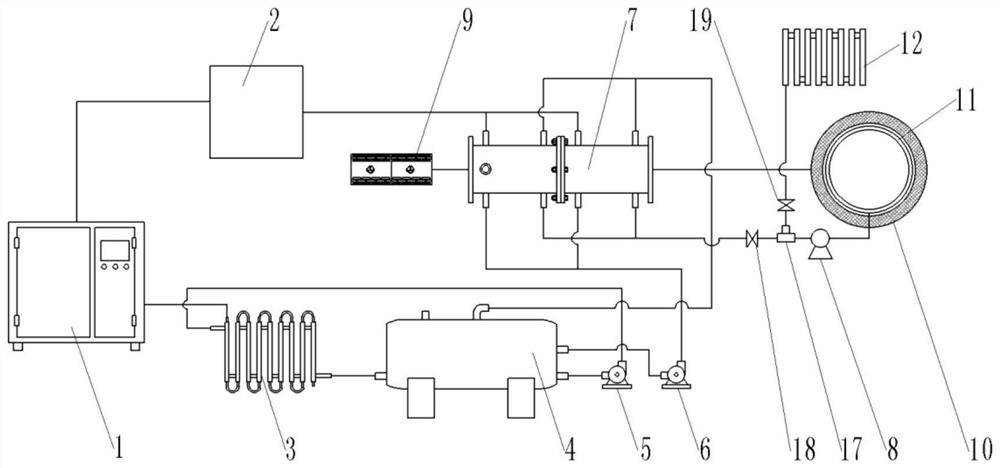

[0042] Example 2: Please refer to figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , a coal slime water energy-saving heating device, comprising an air compressor 1, a hot gas chamber 2, a heat exchanger 3, a water storage tank 4, a first water pump 5, a second water pump 6, a heating mixing pipe 7 and a blower fan 8; by flotation The coal slime water discharged by machine 9 flows into the thickening tank 10 through the heating mixing pipe 7, and the heating mixing pipe 7 is provided with a 180 ° twisted spiral blade 702, and the outer diameter of the spiral blade 702 is slightly smaller than the inner diameter of the heating mixing pipe 7, and the spiral blade 702 is a hollow structure, and the two ends of the helical blade 702 are respectively connected with a first pipe joint 703 communicating with the hollow part of the helical blade 702, and the first pipe joint 703 passes through the pipe wall of the heating mixing pipe 7; the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com