Novel apparatus for solid particle falling

A technology of solid particles and shedding, applied in large containers, containers, loading/unloading, etc., which can solve the problems of troublesome handling and single driving method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

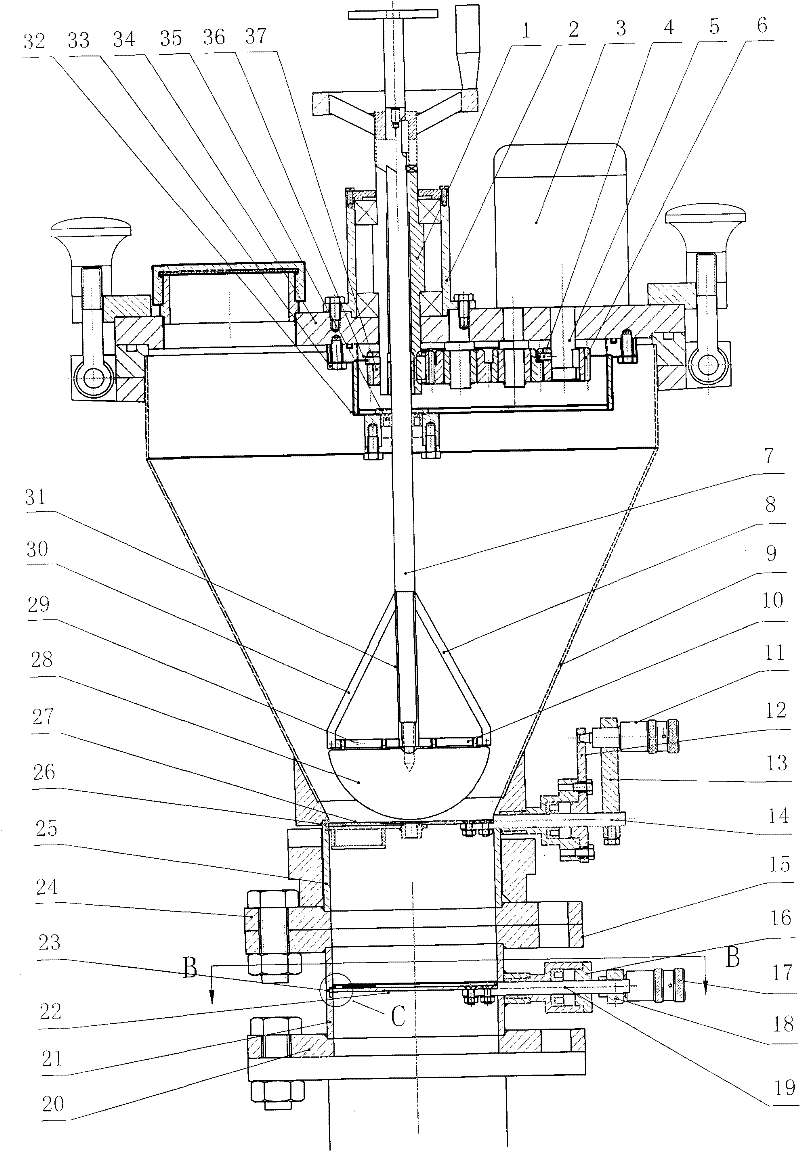

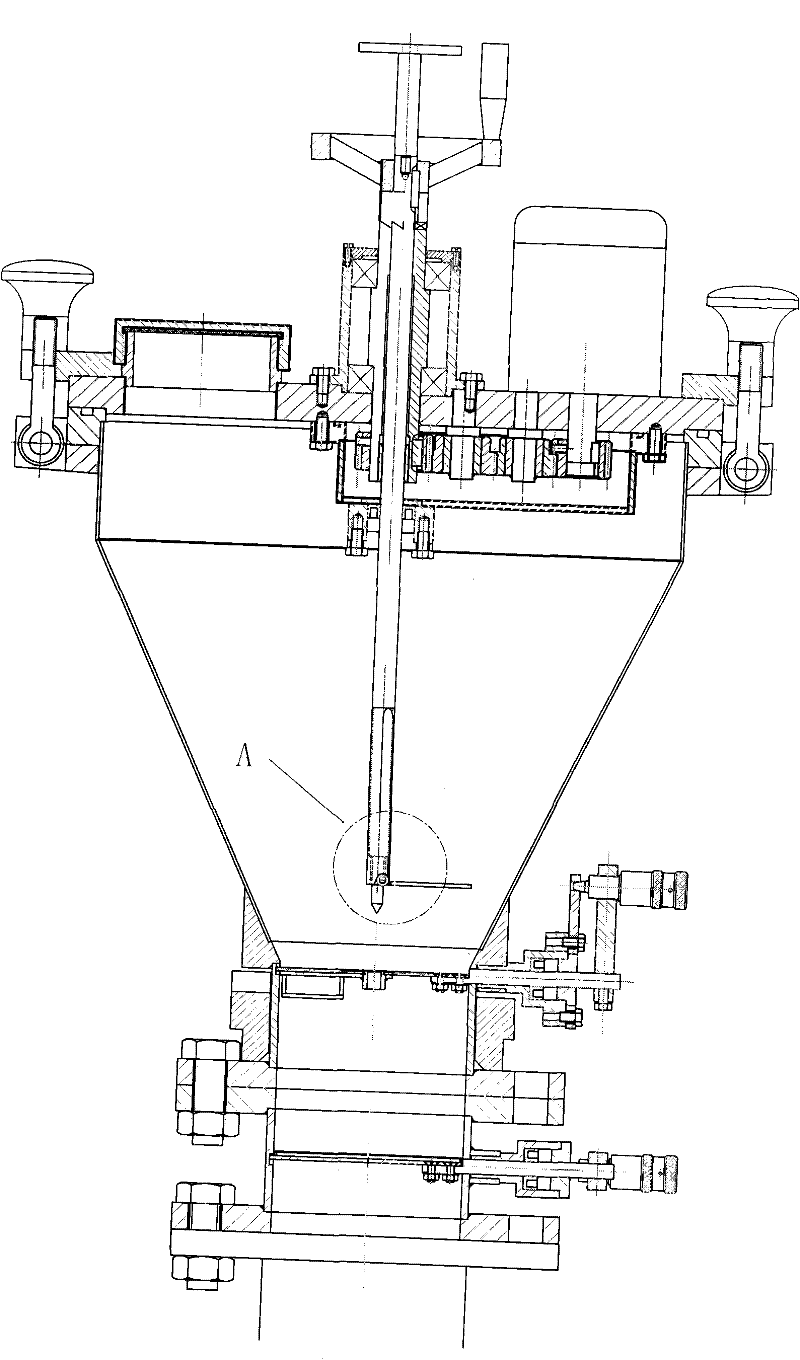

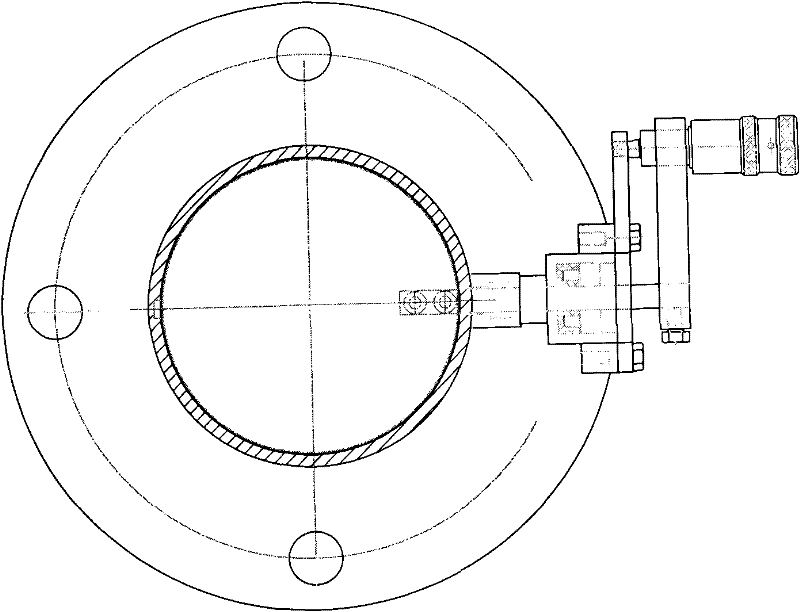

[0024] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Described is a new type of solid particle shaker. There is a vertical stirring shaft 7 in the center of the rounded truss-shaped particle container 9 of the new particle shatter, which is installed in the shaft sleeve 1 on the container cover 34, and it is in motion with the shaft sleeve 1, and can move up and down in the shaft sleeve 1 and turn. A stirring head is installed on the lower end of the vertical stirring shaft 7, and its shape is a part of the envelope of the right cone, namely, the central axis pipe 31 of the stirring head is respectively welded with an equal regular triangle frame 8,30, with two triangular frames The base 10,29 of the bottom edge is connected as a shaft with a rotatable semicircular hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com