Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

一种水泥板、浆液的技术,应用在化学仪器和方法、混合机、水泥搅拌装置等方向,能够解决混合器堵塞、生产中断等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

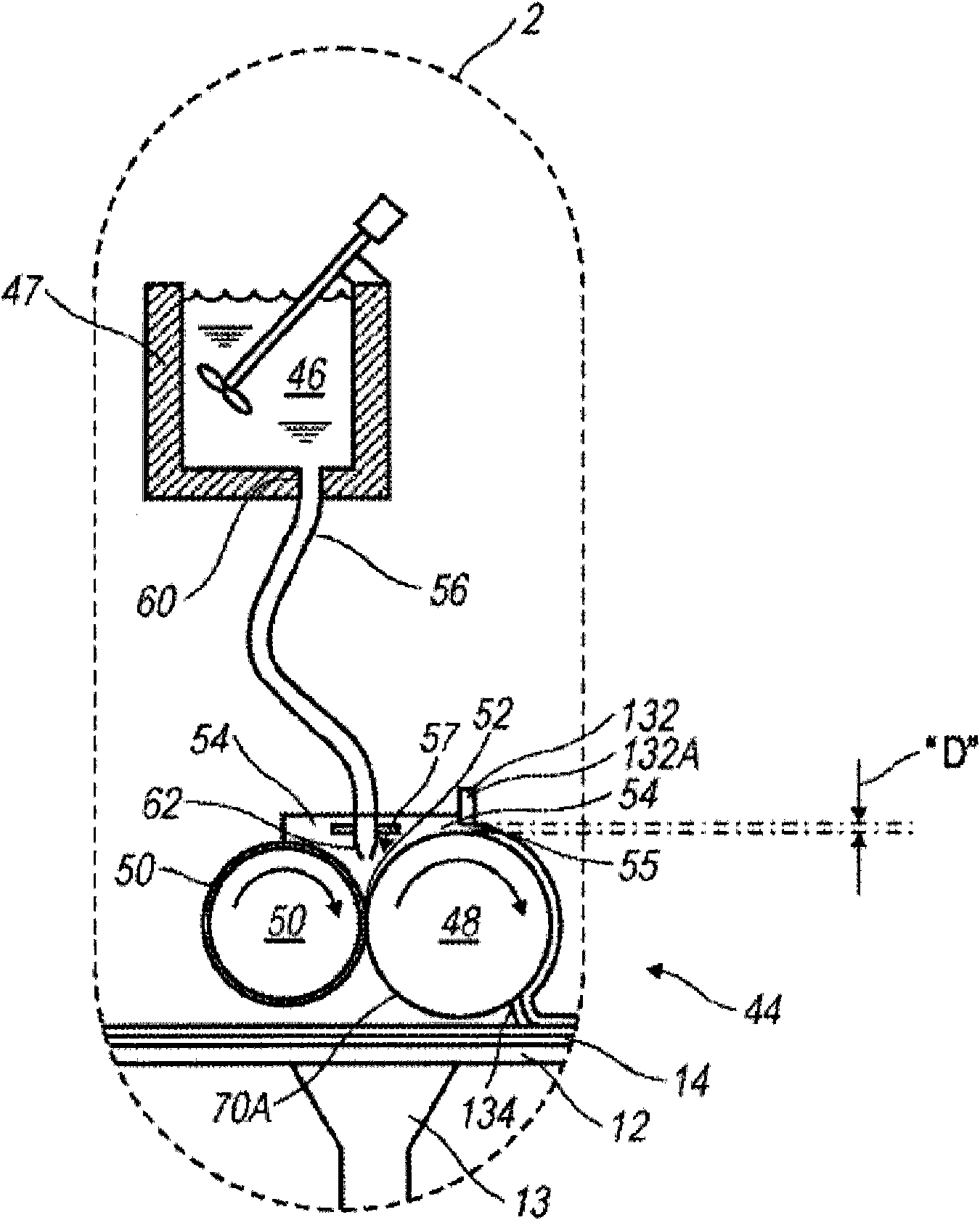

[0146] Introducing the volume percent of loose fibers uniformly distributed in the slurry 46 is an important factor in achieving the desired board strength. Therefore, the addition of these fibers is required to increase efficiency. Believe figure 1 The system shown required in some cases an excessive amount of slurry layer to obtain an SCP panel with a sufficient fiber volume percentage.

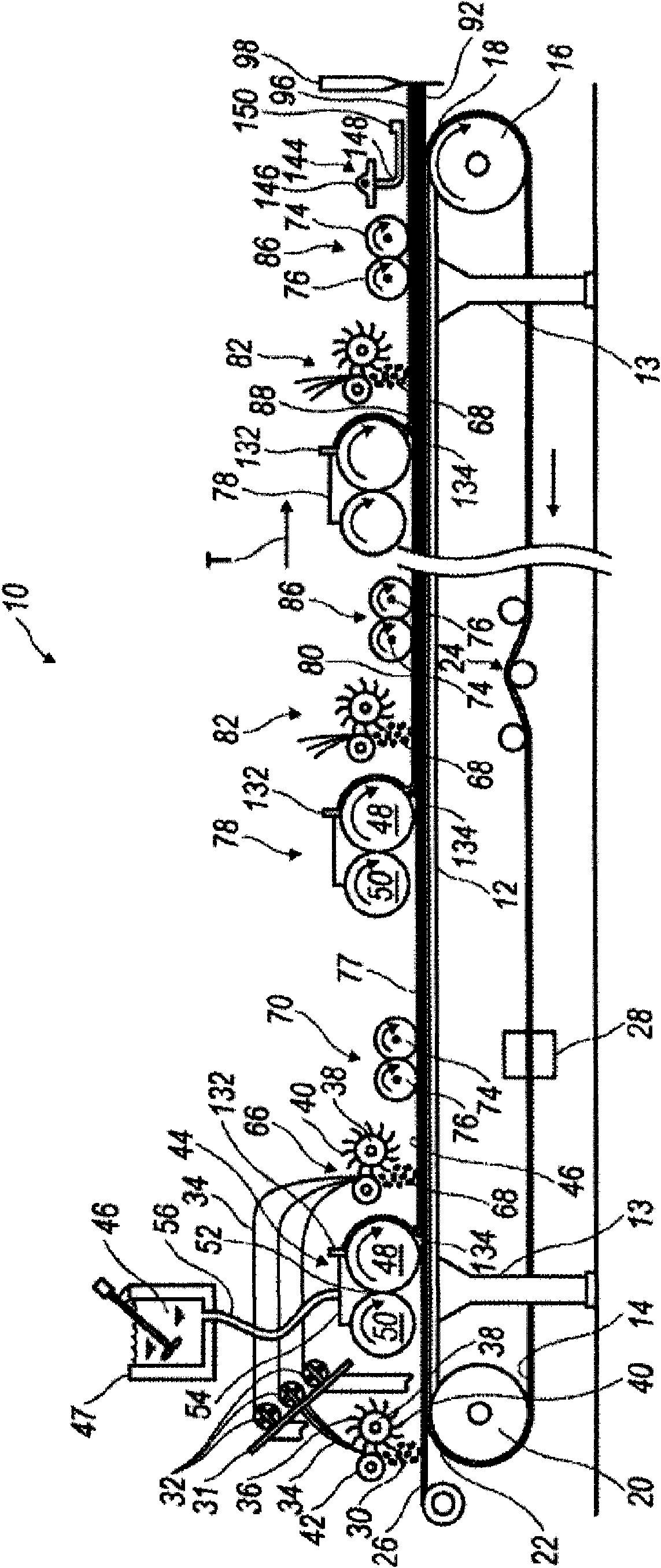

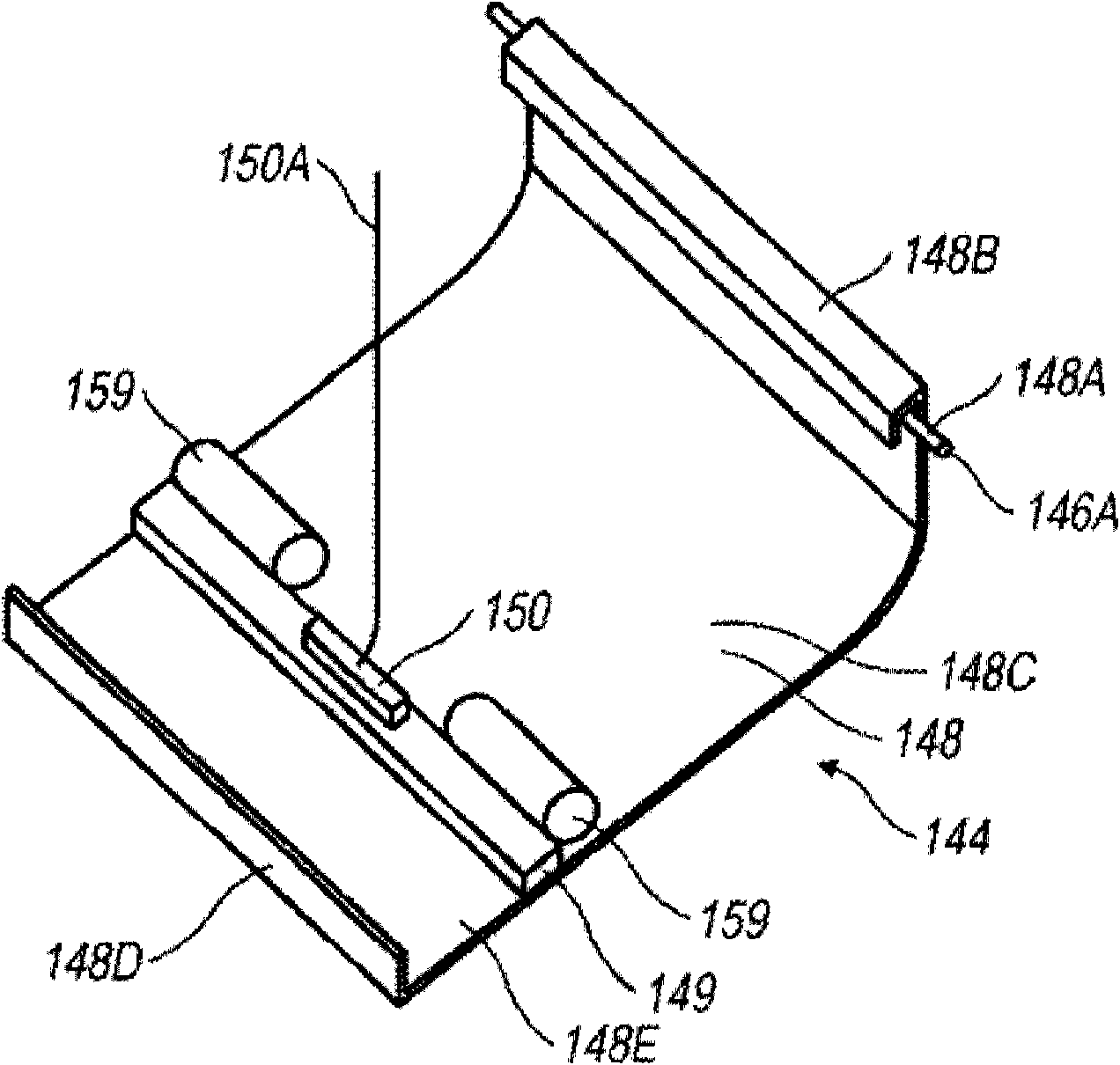

[0147] Therefore, in order to manufacture high-performance, fiber-reinforced SCP panels with relatively large amounts of fibers added to each slurry layer, the Image 6 An alternative SCP board production line or system is shown in and generally indicated at 130 . In many cases, it is possible to obtain an increased content of fibers in each board with this system. Although figure 1 discloses the deposition of a single independent fiber layer in each of the next individual slurry layers deposited after the initial layer, however, the production line 130 includes the accumulation of mu...

example 1

[0242] see figure 1 c, Fragment of SCP panel 92 made of fibers and slurry. The cement portion of the slurry consisted of 65 wt.% calcium sulfate alpha hemihydrate, 22 wt.% type III ordinary Portland cement, 12 wt.% silica fume and 1 wt.% slaked lime. The liquid portion of the slurry included 99.19 wt.% water and 0.81 wt.% ADVACAST superplasticizer manufactured by W.R. Grace and Co. The liquid:cement weight ratio was 0.55 and the aggregate (EXTENDOSPHERES SG microspheres):cement weight ratio was 0.445.

[0243] Using the present system, a slurry is produced according to the current process, with four slurry layers 77, 80, 88 and 90 as shown. Such a board should be considered merely illustrative, as a board 92 made according to the present system may have one or more layers. By using the above mathematical relationship, the size layers 77, 80, 88 and 90 can have different fiber volume percentages. For example, the skin or facing 77, 90 has a specified fiber volume fraction ...

example 2

[0249] The residence time of the wet slurry in the vertical mixing chamber in the different examples was experimentally determined by determining the residence time of the red dyed tracer added to the slurry before the slurry was completely drained from the vertical mixing chamber. Multiple tests were performed to determine residence time in the vertical mixing chamber using a red dyed tracer added to the water and powder slurries upon entry into the vertical mixing chamber. The composition of the cement slurry is about the same as the above-mentioned composition of Example 1.

[0250] The equipment used was a digital scale to weigh the slurry, a barrel to collect the slurry, a stop watch to measure the elapsed time at different points. The mixer was used with three different mixing chamber designs listed in Tables 2-4, namely a 12 inch mixer, an 8 inch extended mixer (Extended Mixer), and an 8 inch stock mixer (Stock Mixer).

[0251] The 8-inch common mixer is the DUO MIX 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com