Method for quickly preparing soil conditioner with municipal sludge

A technology of soil improver and urban sludge, which is applied in the field of preparation of soil improver, can solve the problems of easy to be restricted by external conditions, large loss of organic matter, serious odor pollution, etc., to increase nutrient utilization rate and fast temperature rise , The effect of thorough fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

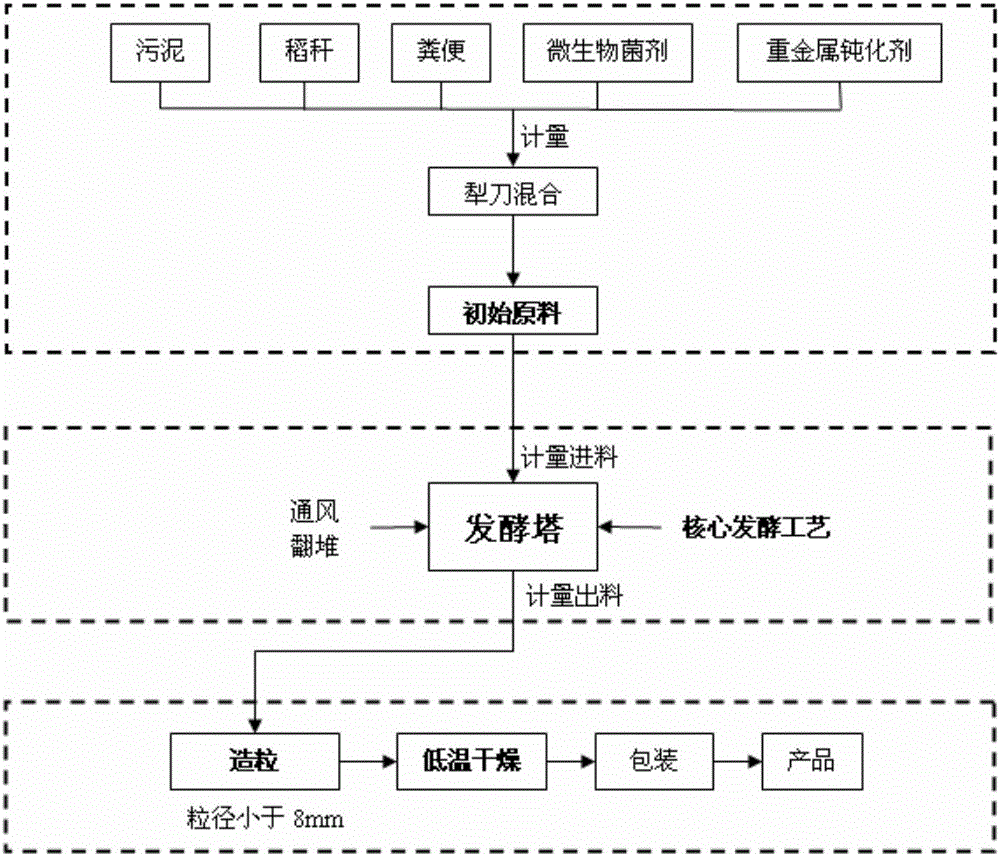

[0057] The production process of using municipal sludge to quickly make soil conditioner is as follows: figure 1 shown.

[0058] Urban domestic sludge (75-85% water content), rice straw (2-5mm in length), livestock and poultry manure, heavy metal passivator (composed of zeolite and bentonite in a mass ratio of 2:1) and microbial agent (composed of White rot fungus, Bacillus licheniformis and Bacillus subtilis radiation-resistant (composed by quantity ratio 2:1:1) are mixed according to mass ratio 60:25:10:4.5:0.5, and enter the coulter mixer, and the mixing time is about 5 minutes. The mixed materials are sent into the multi-layer vertical mixed fermentation tower through the screw conveyor, and the pile height is kept at about 1.5m through the metering equipment, and the parameters in the fermentation process are adjusted to supply air and turn the pile to make the pile Rapid fermentation. Among them, the ventilation volume in the fermentation tower is 0.2m 3 Air / min.m 3 ...

Embodiment 2

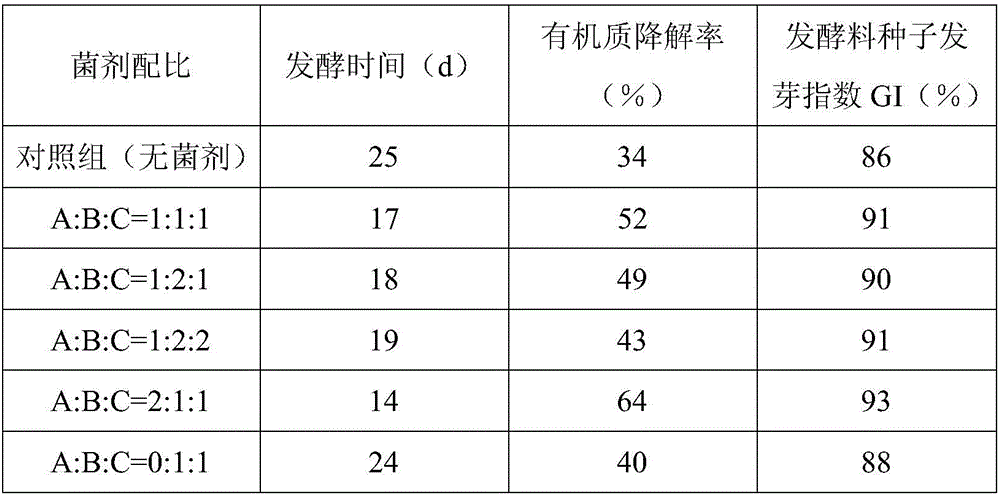

[0063] Control group: the operation steps are as in Example 1, except that different biological agents are used; the white rot fungus is marked as A, the Bacillus licheniformis is marked as B, and the radioresistant Bacillus subtilis is marked as C.

[0064] Table 2 adopts the control experiment group of different microbial bacterial agents

[0065]

[0066]

[0067] Note: The ratio of bacterial agents refers to the ratio of white rot fungi: Bacillus licheniformis: Bacillus subtilis radiation resistant.

[0068] It can be seen from Table 2 that the fermentation effect is optimal when the ratio of the three microorganisms is 2:1:1 through the ratio test of white rot fungi, Bacillus licheniformis and Bacillus subtilis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com