Hot air mixing reaction device

A stirring reaction and hot air technology, which is applied to mixers with rotating stirring devices, mixer accessories, chemical/physical/physicochemical stationary reactors, etc., can solve the problems of not having the function of heat preservation operation, agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

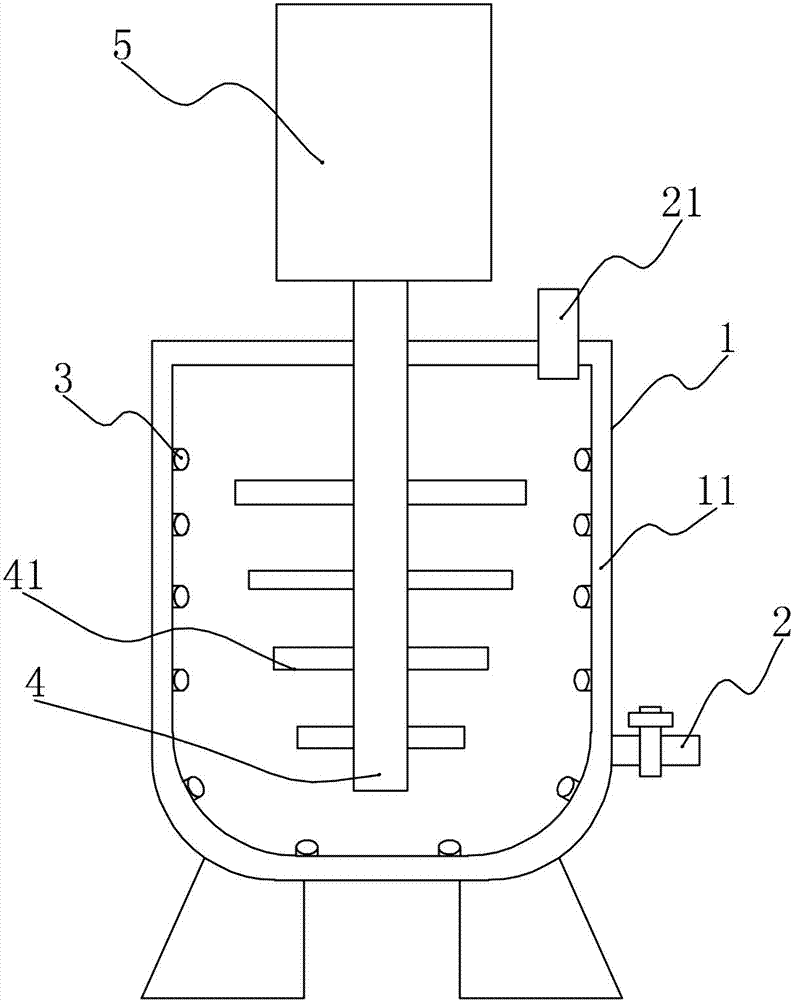

[0010] The hot air stirring reaction device of the present invention comprises a cylinder body 1 which is divided into inner and outer layers, in which there is a hollow layer 11 . A hot air pipe 2 and an exhaust pipe 21 are opened on the cylinder body 1 , the hot air pipe 2 is located at the lower part of the cylinder body 1 , and a stop valve is arranged on the hot air pipe 2 . An air outlet pipe 3 communicating with the hollow layer 11 is provided on the inner wall of the cylinder body 1 , and the air outlet pipe 3 and the stirring blades 41 provided on the stirring rod 4 are vertically spaced apart. The stirring rod 4 is driven by a motor 5 installed on the cylinder body 1 .

[0011] In the present invention, the air outlet pipe 3 communicated with the hollow layer 11 is provided on the inner wall of the cylinder body 1, and the heated air is introduced through the hot air pipe 2, and the hot air enters the cylinder body 1 from the air outlet pipe 3, and is heated by the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com