Novel vertical all-in-one machine for dry and wet feed smashing and mixing

An all-in-one machine, dry and wet technology, applied in the direction of feed, food science, application, etc., can solve the problems of small footprint and the inability of finished materials to meet the different requirements of each household at the same time, to achieve small footprint and airtightness Good, easy to adjust and maintain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

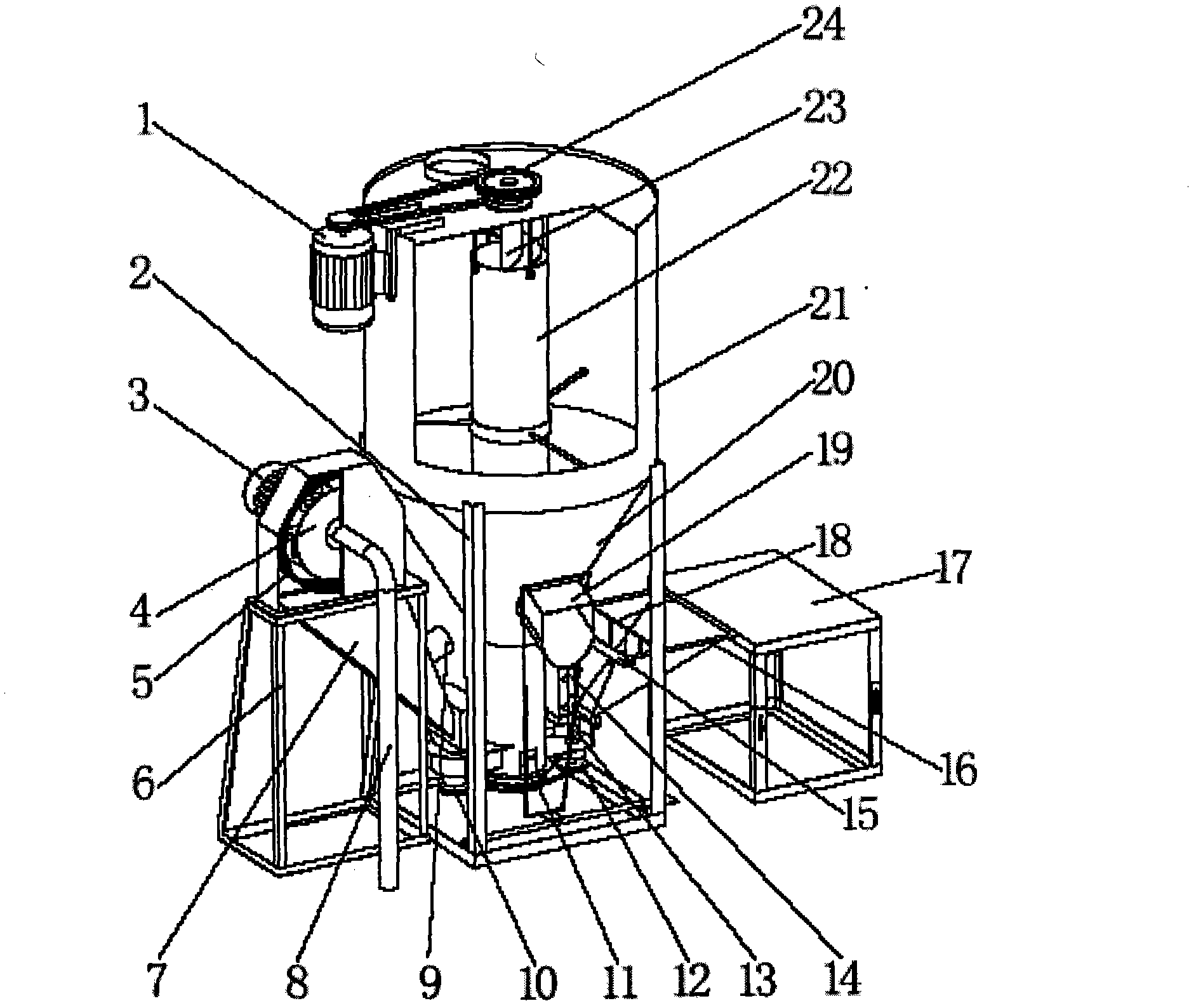

[0012] see figure 1 , the new vertical wet and dry feed crushing and mixing machine drives the vertical spiral stirring shaft 23, the pre-stirring shaft assembly 14, the feeding stirring shaft assembly 13 and the crushing unit respectively by starting the reduction motor 1 and the asynchronous motor 3, and the measured The various dry and wet feeds and additives are poured into the main feed hopper 16 on one side through the height-adjustable workbench 17 by the operator in turn, pre-stirred by the pre-stirring shaft, and brought into the bottom of the screw shaft auger through the feeding stirring shaft. At the same time, the corn on the other side enters the crushing chamber through the suction pipe 8. Under the impact of the high-speed rotating hammer 4 and the friction of the sieve plate, the corn is gradually crushed, and under the action of centrifugal force and airflow, it passes through the discharge chamber. It is discharged from the feeding port, enters the auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com