Circulatory fluid-supply cleaning system

A cleaning system and liquid supply technology, applied in the field of parts cleaning, can solve problems such as low efficiency, inefficiency, and parts corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

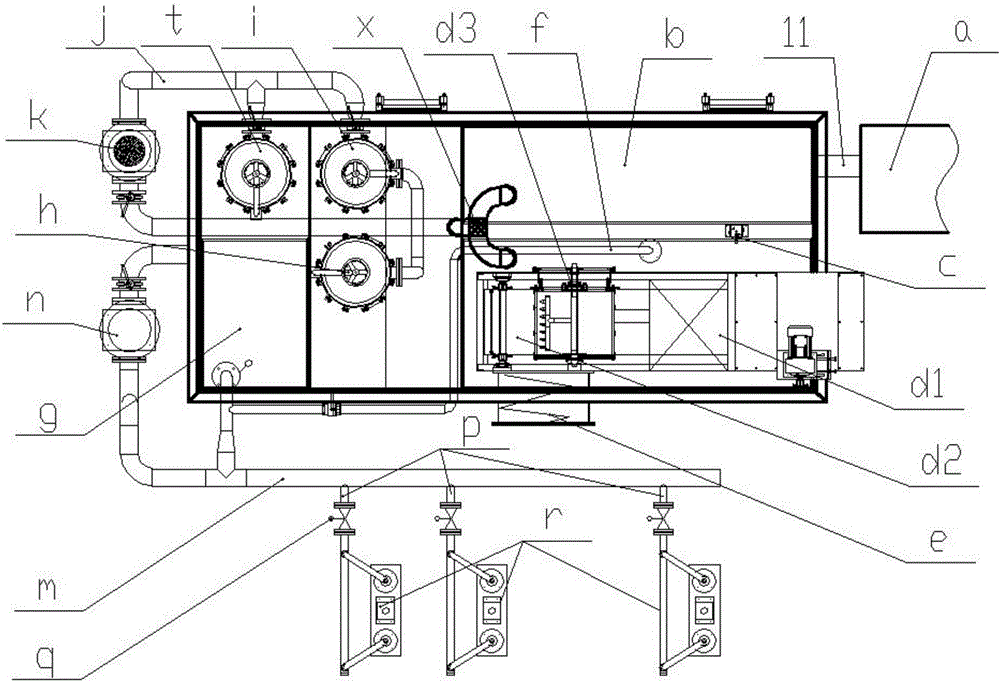

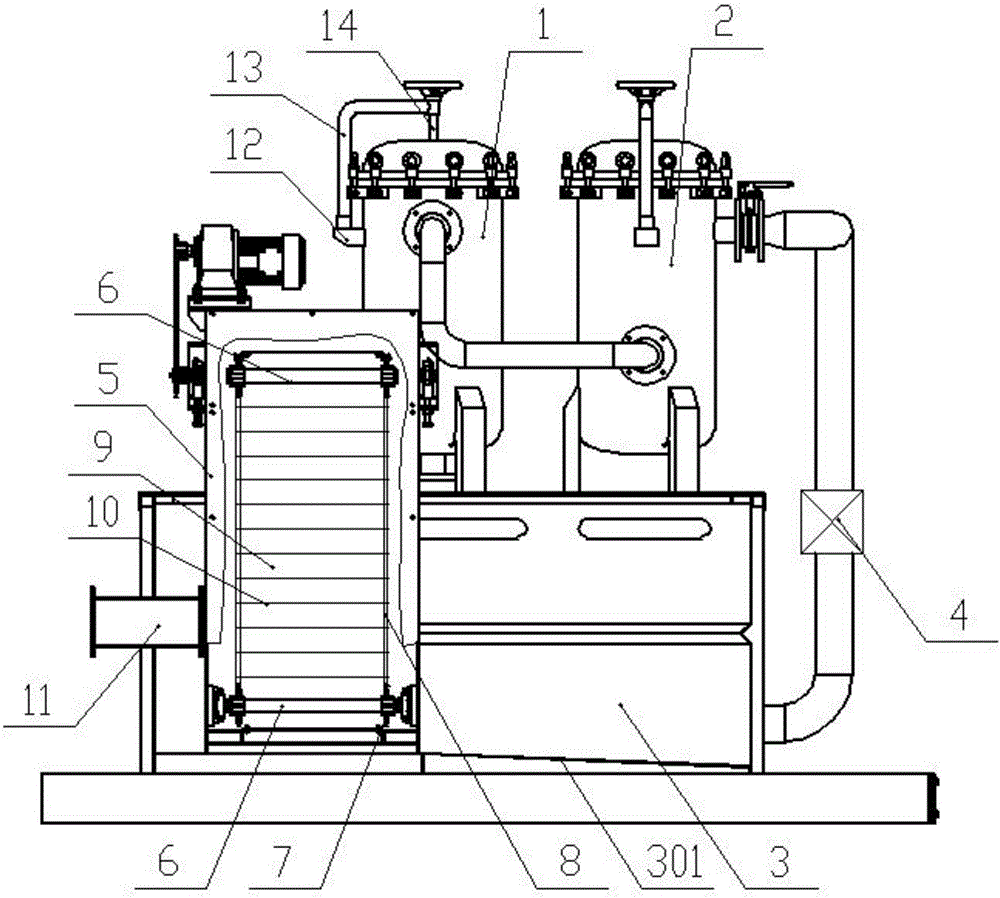

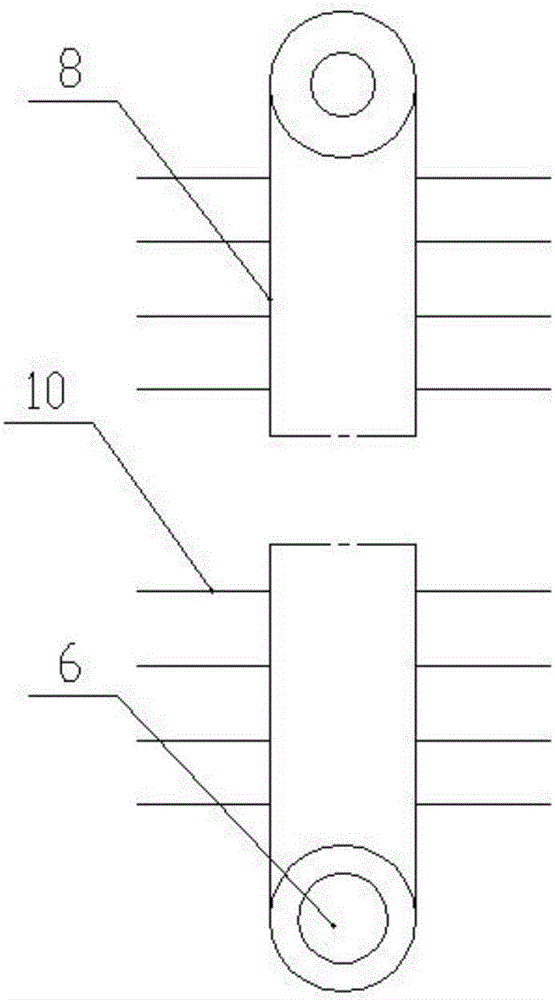

[0022] like figure 1 Shown in -3, a kind of circulating liquid supply cleaning system, comprises the dispensing machine a of the required liquid medicine of preparation ultrasonic cleaning; Described dispensing machine a comprises the first equipped bucket 1 and the second equipped bucket 2 that are provided with stirring bar, the first The upper part of the first equipped barrel 1 communicates with the lower part of the second equipped barrel 2, and a valve is set to control on-off; There are pumps 4 and control valves. The bottom bin 3 is located below the first equipped barrel 1 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com