Foamed nickel-loaded zinc titanate photocatalytic material and preparation method thereof

A photocatalytic material, zinc titanate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of harsh catalytic regeneration conditions and ceramic tensile strength Poor, small effective area and other problems, to achieve the effect of superior performance, low manufacturing cost, no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

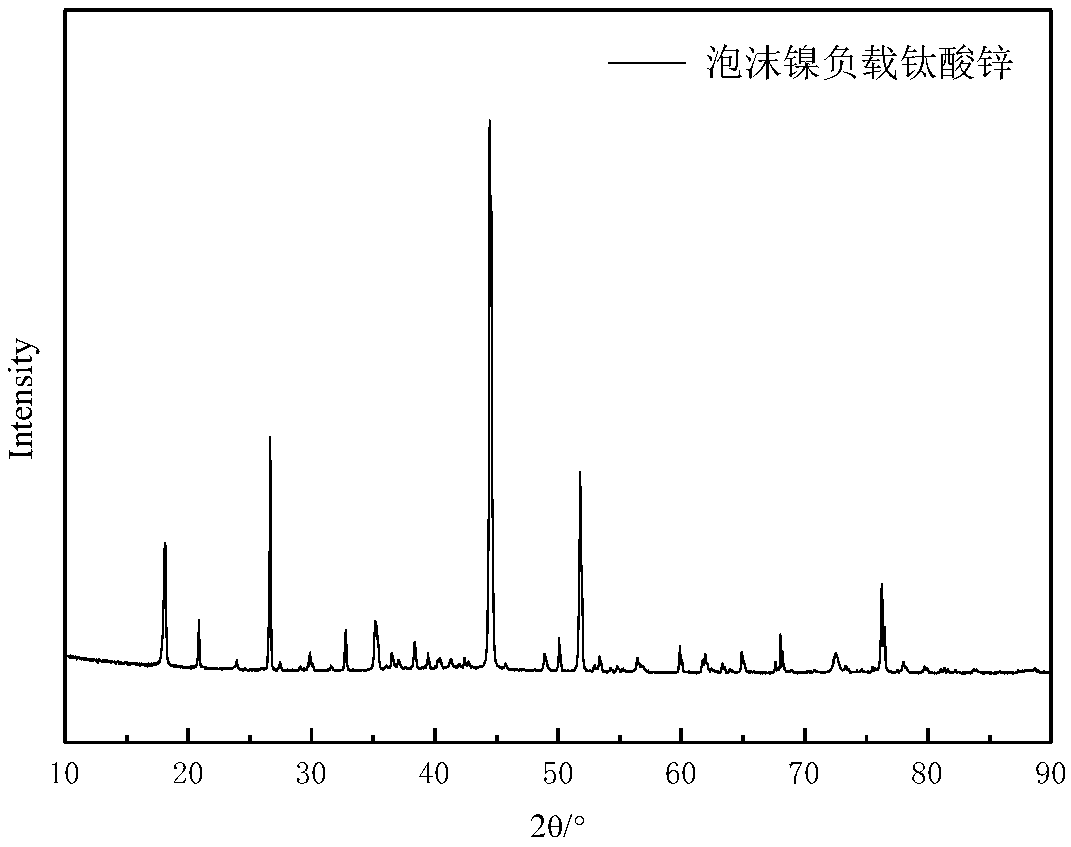

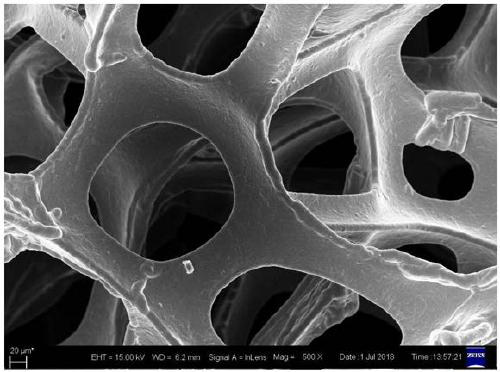

[0043] Preparation method of nickel foam supported zinc titanate photocatalytic material

[0044] Soak nickel foam (2cm×5cm) in absolute ethanol for 20min, then take it out, rinse it with deionized water, then soak it in 0.1mol / L dilute hydrochloric acid for 10min, after taking it out, ultrasonically clean it with deionized water Wash for 20 minutes, dry at 80°C for 5 hours and set aside;

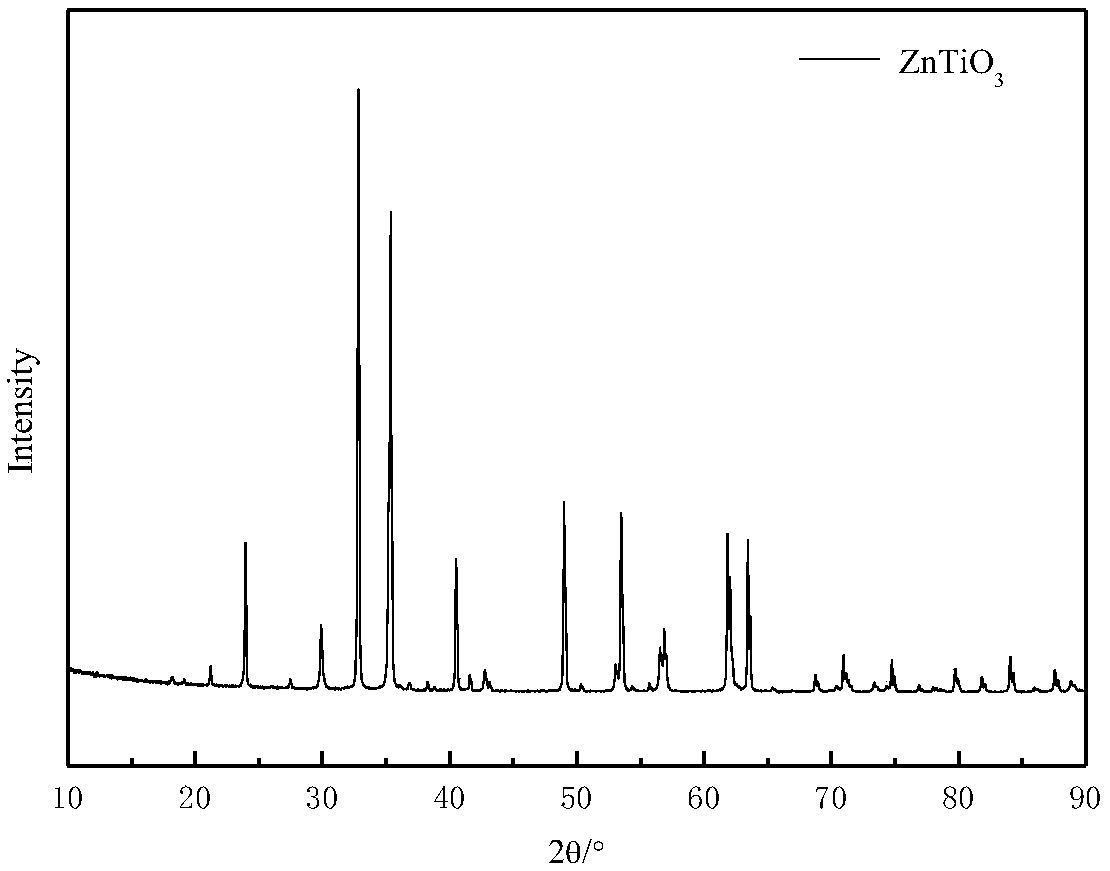

[0045] ZnTiO 3 and SiO 2 Mix evenly according to the mass ratio: 1:1.2, and then put it into an agate mortar for grinding for 10 minutes;

[0046] Mix polytetrafluoroethylene (PTFE) and absolute ethanol at a volume ratio of 1:5, and then magnetically stir for 4 minutes to form a uniform suspension A; under the condition of magnetic stirring, grind ZnTiO 3 / SiO 2 Put the mixed powder into the above-mentioned suspension A, and continue to stir for 5 minutes to form a uniform suspension B;

[0047] Evenly coat the suspension B on a nickel foam (2cm×5cm) sheet, then place it in a drying bo...

Embodiment 2

[0049] Preparation method of nickel foam supported zinc titanate photocatalytic material

[0050] Soak nickel foam (2cm×5cm) in absolute ethanol for 20min, then take it out, rinse it with deionized water, then soak it in 0.1mol / L dilute hydrochloric acid for 10min, after taking it out, ultrasonically clean it with deionized water Wash for 20 minutes, dry at 80°C for 5 hours and set aside;

[0051] ZnTiO 3 and SiO 2 Mix evenly according to the mass ratio of 1:1, and then put it into an agate mortar and grind for 10 minutes;

[0052] Mix polytetrafluoroethylene (PTFE) and absolute ethanol at a volume ratio of 1:5, and then magnetically stir for 4 minutes to form a uniform suspension A; under the condition of magnetic stirring, grind ZnTiO 3 / SiO 2 Put the mixed powder into the above-mentioned suspension A, and continue to stir for 5 minutes to form a uniform suspension B;

[0053] The suspension B is evenly coated on the nickel foam (2cm × 5cm) sheet, then it is placed in a...

Embodiment 3

[0055] Preparation method of nickel foam supported zinc titanate photocatalytic material

[0056] Soak nickel foam (2cm×5cm) in absolute ethanol for 20min, then take it out, rinse it with deionized water, then soak it in 0.1mol / L dilute hydrochloric acid for 10min, after taking it out, ultrasonically clean it with deionized water Wash for 20 minutes, dry at 80°C for 5 hours and set aside;

[0057] ZnTiO 3 and SiO 2 Mix evenly according to the mass ratio: 1:0.8, and then put it into an agate mortar for grinding for 10 minutes;

[0058] Mix polytetrafluoroethylene (PTFE) and absolute ethanol at a volume ratio of 1:5, and then magnetically stir for 4 minutes to form a uniform suspension A; under the condition of magnetic stirring, grind ZnTiO 3 / SiO 2 Put the mixed powder into the above-mentioned suspension A, and continue to stir for 5 minutes to form a uniform suspension B;

[0059] The suspension B is evenly coated on the nickel foam (2cm × 5cm) sheet, then it is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com