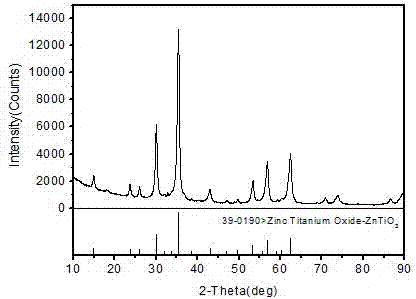

Preparation method for zinc titanate photocatalytic material with special morphology

A photocatalytic material, zinc titanate technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, titanium compounds, etc., can solve problems such as unsuitable production efficiency, expensive raw materials, and long preparation time , to shorten the production cycle, improve dispersion, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: the preparation method of the zinc titanate photocatalytic material with special morphology in this embodiment is carried out according to the following steps:

[0032] 1. Weigh polyvinylpyrrolidone (PVP), zinc nitrate hexahydrate and tetrabutyl titanate according to the ratio of surfactant, Zn element and Ti element substance ratio of 1:40:40, and prepare 0.0005mol respectively at room temperature / L, 0.05 mol / L and 0.05 mol / L ethylene glycol solutions, and slowly mix zinc nitrate hexahydrate and tetrabutyl titanate solutions evenly to obtain a mixed solution;

[0033] 2. Using polyvinylpyrrolidone (PVP) solution as the mother liquor, slowly drop the mixed solution and 25 wt% concentrated ammonia solution into the mother liquor at the same time, and stir vigorously to control the acid-base of the reaction system to be neutral (pH≈7) , to generate zinc titanate precursor Zn(OH) 2 / TiO(OH) 2 the suspension;

[0034] 3. Centrifuge the suspensio...

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the zinc source, titanium source and solvent described in step one are ZnSO 4 、TiOSO 4 and distilled water, the basic equation of precursor precipitation is shown in formula (5), and the solvent used for the corresponding precursor washing should also be distilled water, and the others are the same as in Embodiment 1.

[0046] TiOSO 4 +ZnSO 4 +NH 3 ·H 2 O→Zn(OH) 2 ↓+TiO(OH) 2 ↓+2(NH 4 ) 2 SO 4 (5)

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the surfactant and precipitating agent described in step one are PEG400 and Na 2 CO 3 , the others are the same as in the second embodiment.

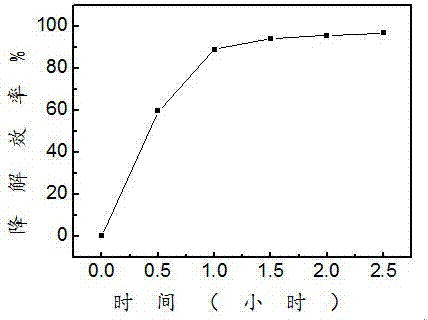

[0048] The beneficial effects of this embodiment are: the cubic phase ZnTiO synthesized by this embodiment 3 The material has uniform morphology and uniform size, and the use of PEG400 can effectively control the ZnTiO 3 The growth direction of the crystal, making it form spherical or nearly spherical ZnTiO 3 The material and particles show a good dispersion state, no serious agglomeration and large accumulation phenomenon, and the particle size is mostly around 80nm. Due to quantum effects induced by nanoparticles, ZnTiO 3 The conduction band and valence band of the material become discrete energy levels, the energy gap widens, and the energy of photogenerated electrons and holes is higher, thus having stronger oxidation-red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com