Flue gas treatments to reduce NOx and CO emissions

A flue gas and flue technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The following examples are only to illustrate the present invention, and are not intended to limit the scope of protection of the appended claims.

[0042] An FCC unit with typical operating conditions was used in this test. For example, an FCC unit with a regenerator temperature of about 1350°F, a feed rate of about 90,000 bbl / day, a conversion of about 75%, and excess O at the regenerator exit / stack start 2 The concentration is about 0.5%; excess O in the flue (at the tail end of the flue) 2 The concentration was about 1%; the basic nitrogen content in the feed was about 300 ppm.

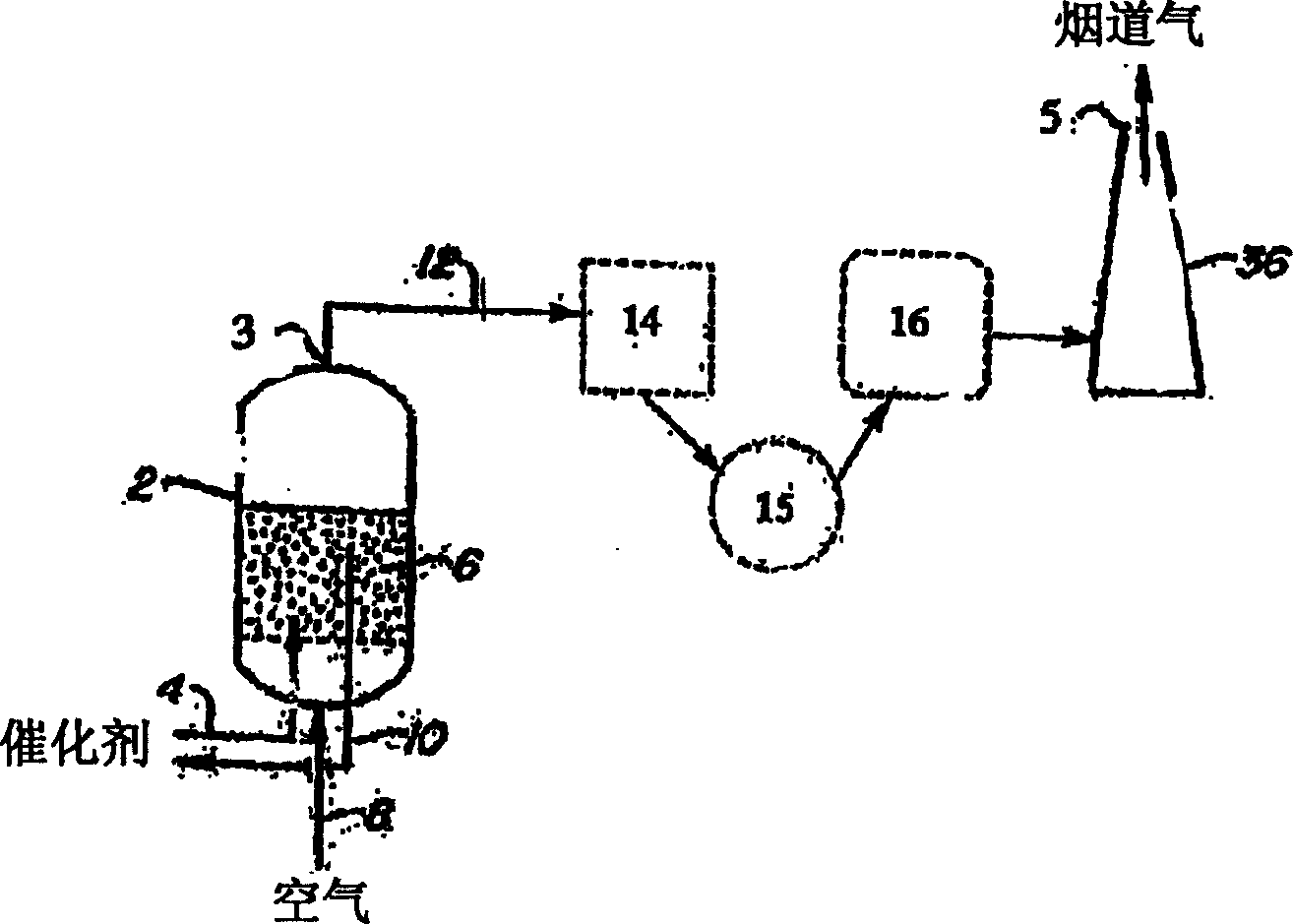

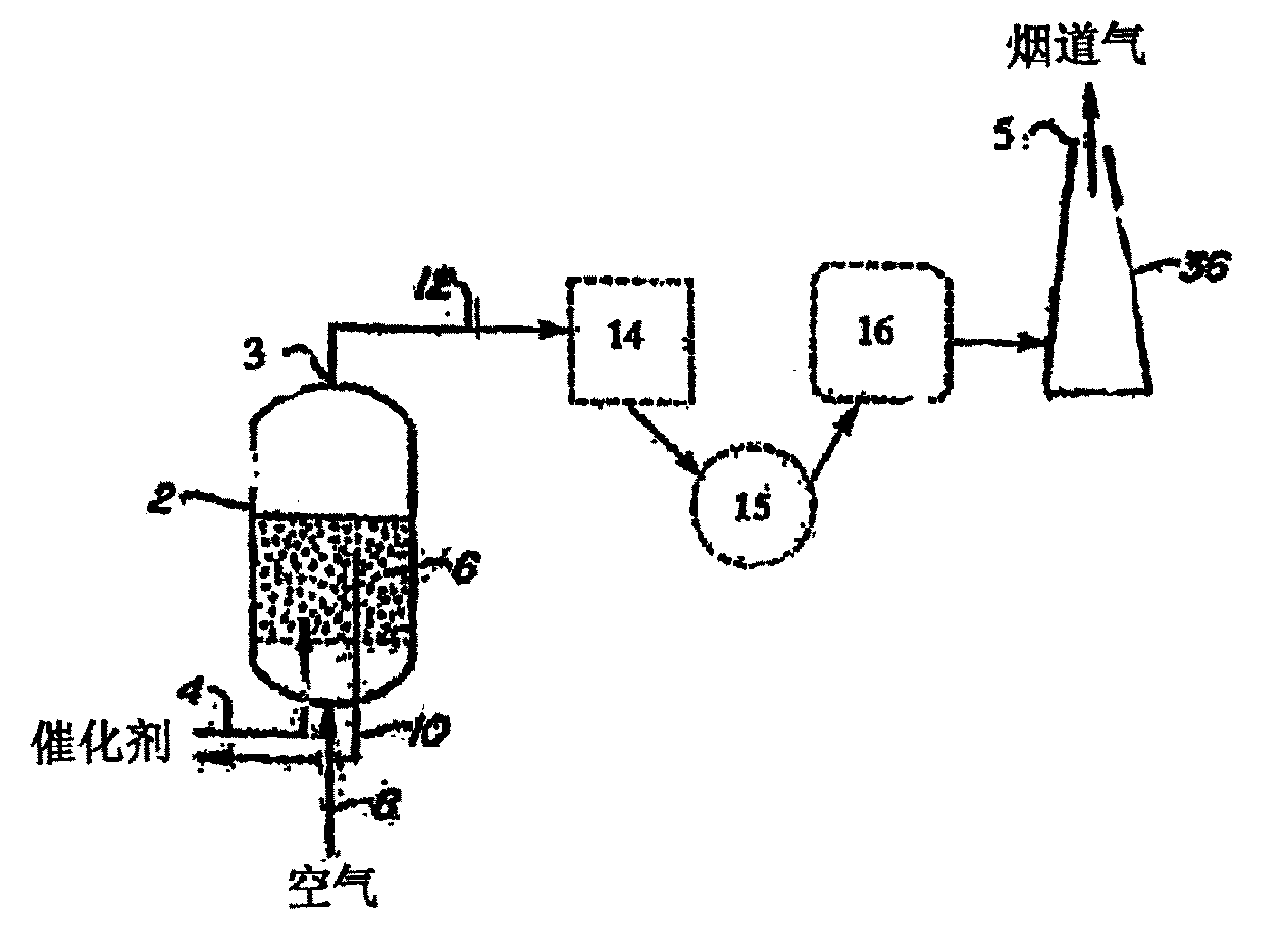

[0043] refer to figure 1 , before adding the composition of the invention to the FCC unit, measure NO in the regeneration furnace 2 of the FCC unit as close as practically possible to the beginning of the flue 3 and the tail end of the flue 5 x and CO emissions.

[0044] The composition of the present invention was added to the FCC regenerator in an amount of about 0.04% by weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com