Nickel oxide-doped niobium zinc titanate microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and zinc niobium titanate, applied in the field of ceramic compositions, can solve the problems of high sintering temperature, decreased dielectric properties, low dielectric constant, etc., and achieves the effects of good comprehensive performance and improved relative dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention is as follows:

[0033] (1) Ingredients

[0034] The raw materials ZnO, Nb 2 o 5 、TiO 2 and Ni 2 o 3 Press (Zn 1-x Ni x )TiNb 2 o 8 , where the stoichiometric ratio of x=0.1 to 0.4 is mixed and put into a ball mill tank for ball milling; the ball milling medium is deionized water and zirconia balls, the weight ratio of balls:material:water is 2:1:0.6; ball milling 6h , with a rotation speed of 800 rpm, then put the mixture into an oven to dry at 90°C, then put it into a mortar for grinding, and pass through a 40-mesh sieve;

[0035] (2) synthesis

[0036] Put the powder sieved in step (1) into a crucible, compact it, cover it, synthesize it in a synthesis furnace at 1050°C, keep it warm for 4 hours, cool it down to room temperature naturally, and take it out of the furnace;

[0037] (3) Secondary ball milling

[0038] After the synthetic material in step (2) is ground, put it into a ball mill tank for ball mill...

specific Embodiment

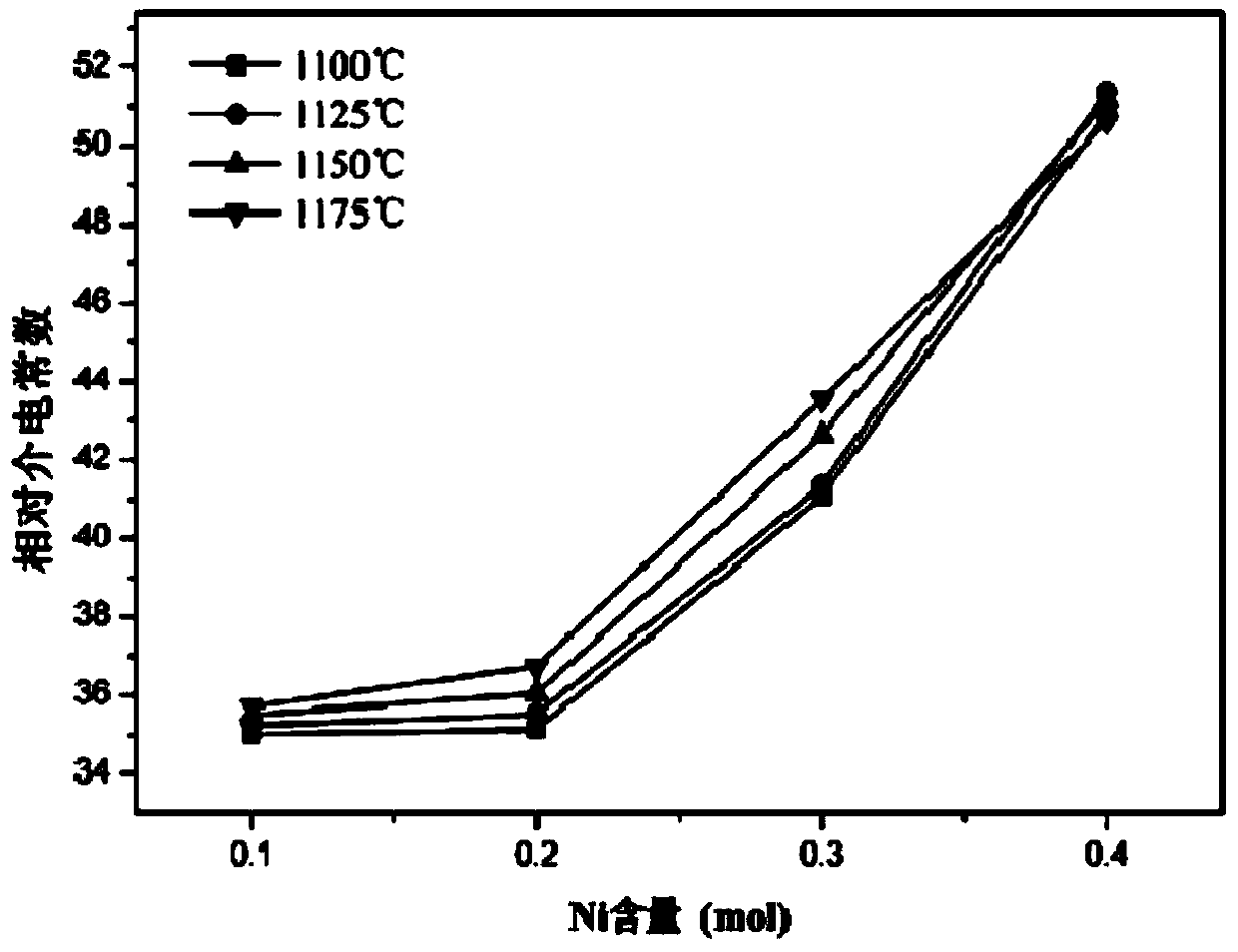

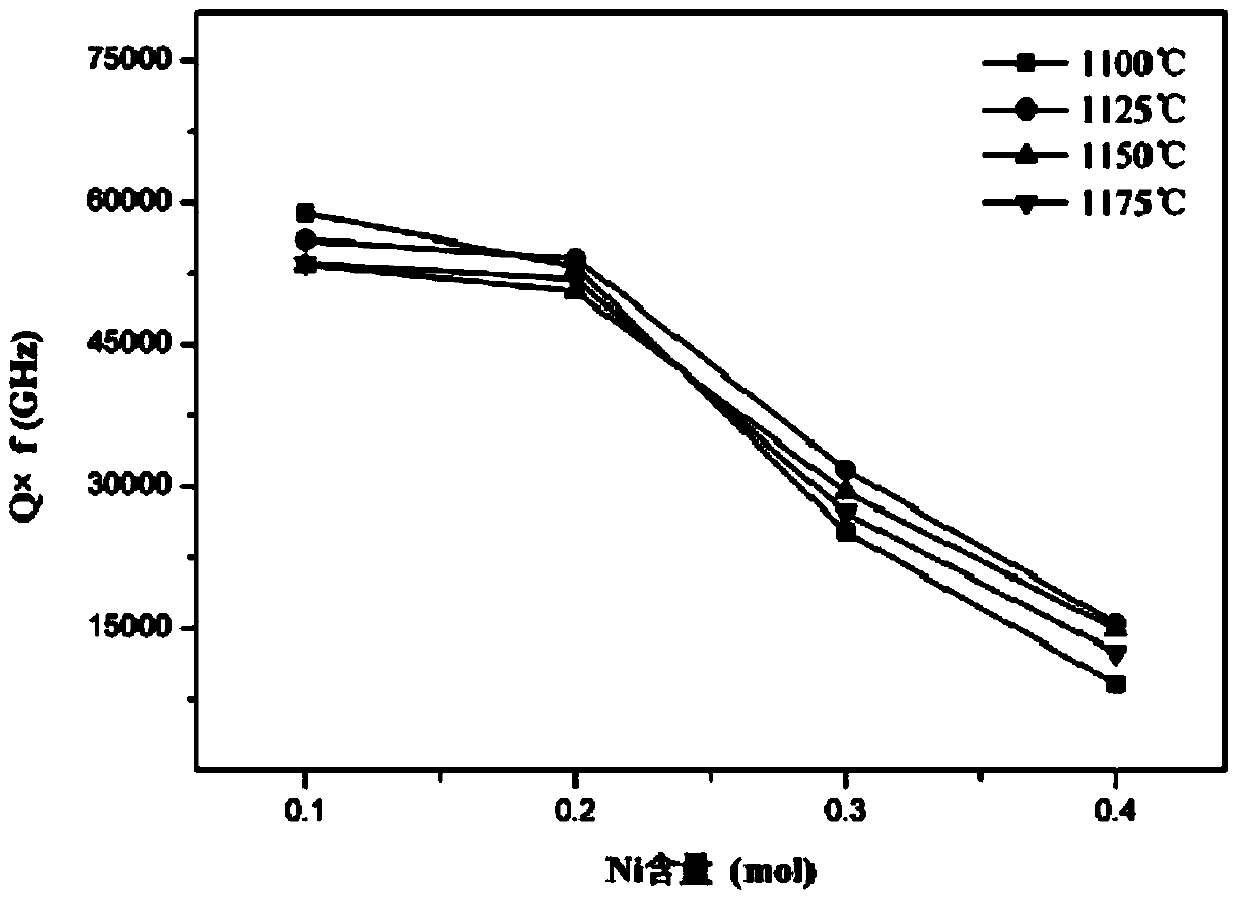

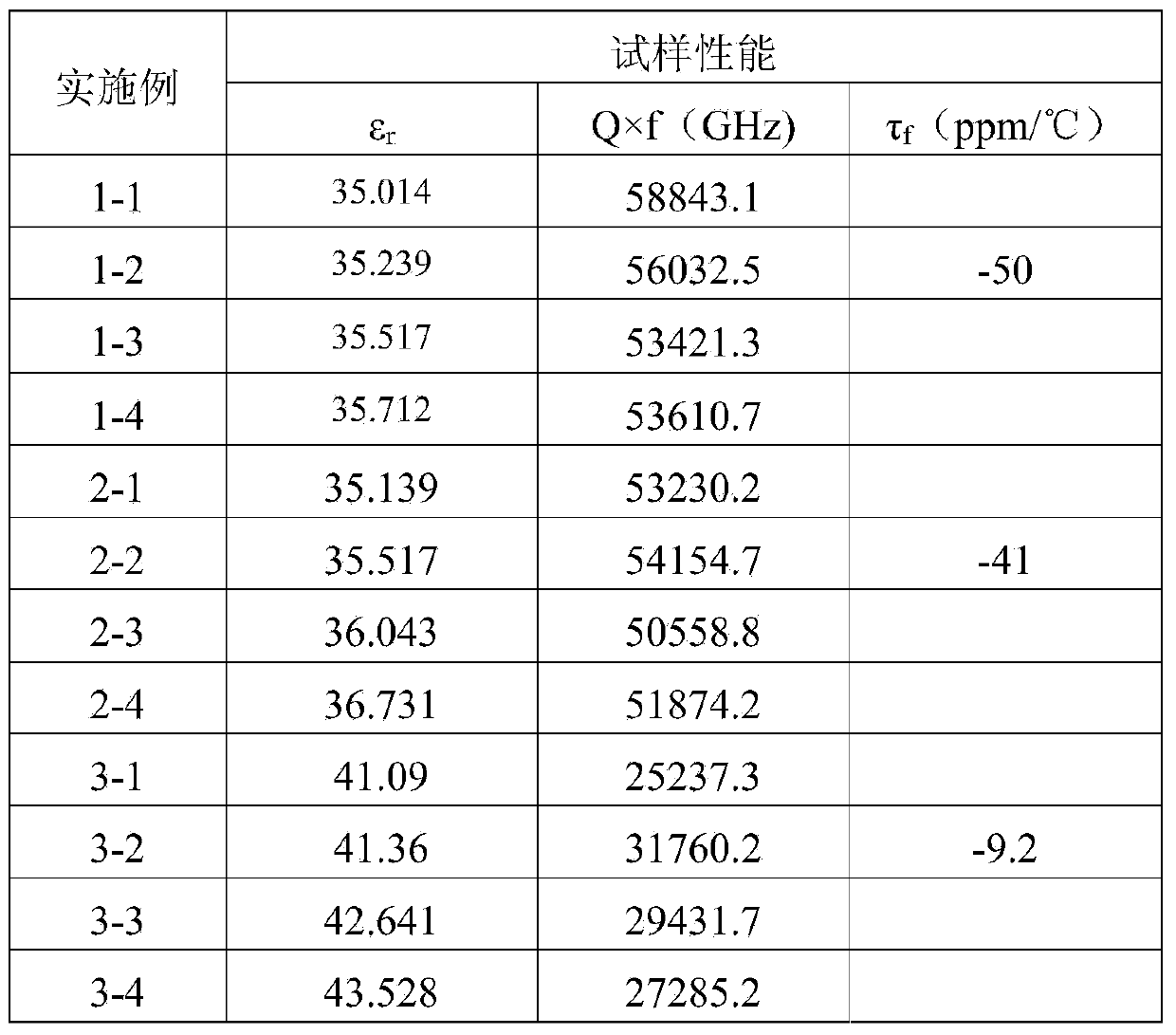

[0048] x=0.1, the sintering temperature is 1100°C, 1125°C, 1150°C, and 1175°C, which are respectively recorded as Examples 1-1, 1-2, 1-3, and 1-4;

[0049] x=0.2, the sintering temperature is 1100°C, 1125°C, 1150°C, 1175°C, which are respectively recorded as Examples 2-1, 2-2, 2-3, and 2-4;

[0050] x=0.3, the sintering temperature is 1100°C, 1125°C, 1150°C, and 1175°C, which are respectively recorded as Examples 3-1, 3-2, 3-3, and 3-4;

[0051] x=0.4, the sintering temperature is 1100°C, 1125°C, 1150°C, and 1175°C, which are respectively recorded as Examples 4-1, 4-2, 4-3, and 4-4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com