Zinc titanate micro-nano photocatalysis material and preparation method thereof

A photocatalytic material, zinc titanate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of adding surfactants, complex preparation process, Unfavorable problems such as industrial production, to achieve the effect of reducing the preparation cost, the preparation method is simple, and the production cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 2.00g industrial grade common TiO 2powder, add 20mL ammonia water with a mass concentration of 10% while stirring, ultrasonically disperse for 1 hour, transfer to a 50mL polytetrafluoroethylene bottle with a screw cap and seal it, and continue stirring at 50°C for 3 hours to obtain a white suspension A ; Then 681.5mL concentration of 5g / L zinc chloride aqueous solution is slowly poured into the white suspension A with the zinc salt solution under rapid stirring to obtain the white suspension B; then the white suspension B is moved into a closed autoclave, After being treated at 50°C and 0.5MPa for 2 hours under continuous stirring, take it out and repeatedly centrifuge and wash with deionized water until the ammonium ions and chloride ions are completely removed to obtain precursor C; After the wind is completely dry, transfer to a crucible electric furnace and roast at 800°C for 2 hours, and ball mill the roasted product to obtain zinc titanate powder. The prepa...

Embodiment 2

[0037] Weigh 1.50g industrial grade common TiO 2 powder, add 15mL ammonia water with a mass concentration of 15% while stirring, ultrasonically disperse for 0.5 hours, transfer to a 50mL polytetrafluoroethylene bottle with a screw cap and seal, and continue stirring at 100°C for 1 hour to obtain a white suspension A ; Then 539.0mL concentration of 10g / L zinc sulfate aqueous solution is slowly poured into the white suspension A with the zinc salt solution under rapid stirring to obtain the white suspension B; then the white suspension B is moved into a closed autoclave, After being treated at 65°C and 1.0MPa for 1.5 hours under continuous stirring, take it out and repeatedly centrifuge and wash with deionized water until the ammonium ions and sulfate ions are completely removed to obtain the precursor C; finally, the precursor C is freeze-dried , transferred to a crucible electric furnace and roasted at 600 ° C for 4 hours, and ball milled the roasted product to obtain zinc tit...

Embodiment 3

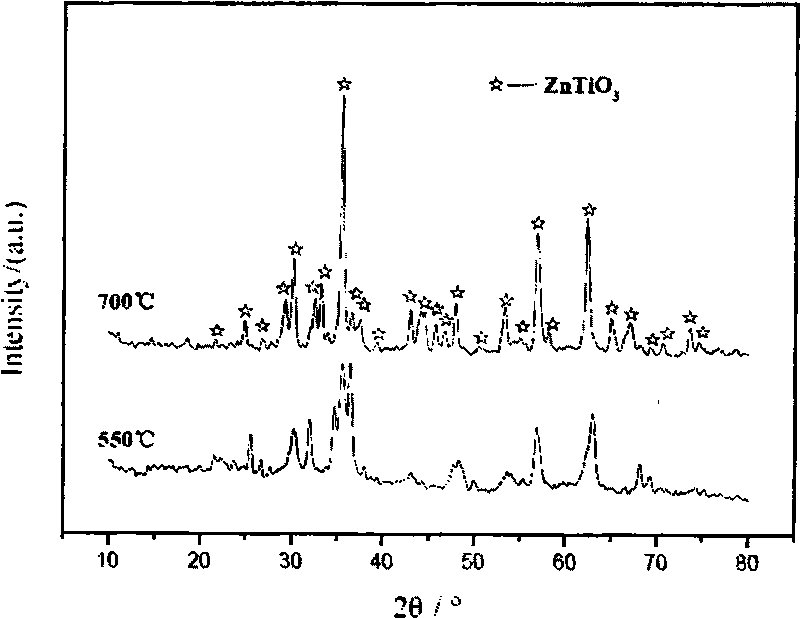

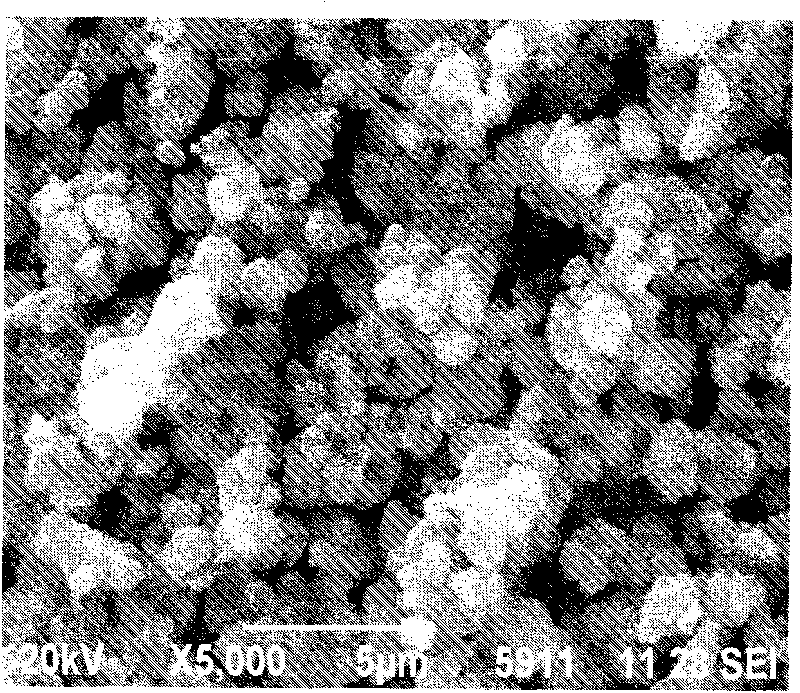

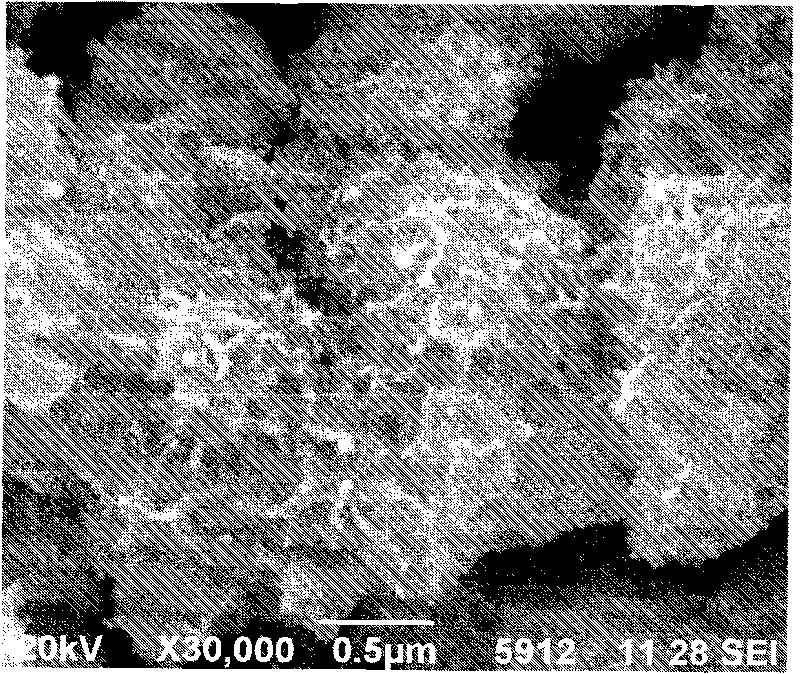

[0040] Weigh 3.50g industrial grade common TiO 2 powder, add 35mL of 15% ammonia water while stirring, ultrasonically disperse for 2 hours, transfer to a 50mL polytetrafluoroethylene bottle with a screw cap and seal it, and keep stirring at 85°C for 2 hours to obtain a white suspension A; then 597mL The zinc nitrate aqueous solution with a concentration of 20g / L was slowly poured into the white suspension A under rapid stirring to obtain the white suspension B; then, the white suspension B was moved into a closed autoclave, and kept stirring at 75 After treatment at ℃ and 1.2MPa for 2 hours, take it out and repeatedly centrifuge and wash it with deionized water until the ammonium ions and nitrate ions are completely removed to obtain the precursor C; finally freeze-dry the precursor C and transfer it to a crucible electric furnace Calcined at 550°C for 3.5 hours, ball milled the calcined product to obtain zinc titanate powder. The prepared zinc titanate has a spherical struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com