ZnO-TiO2 series low-temperature co-burning ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics, zno-b2o3-sio2, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of material properties or processes that are difficult to meet the requirements, casting and other problems, and achieve flexible design models or structures, low cost, and electrical good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

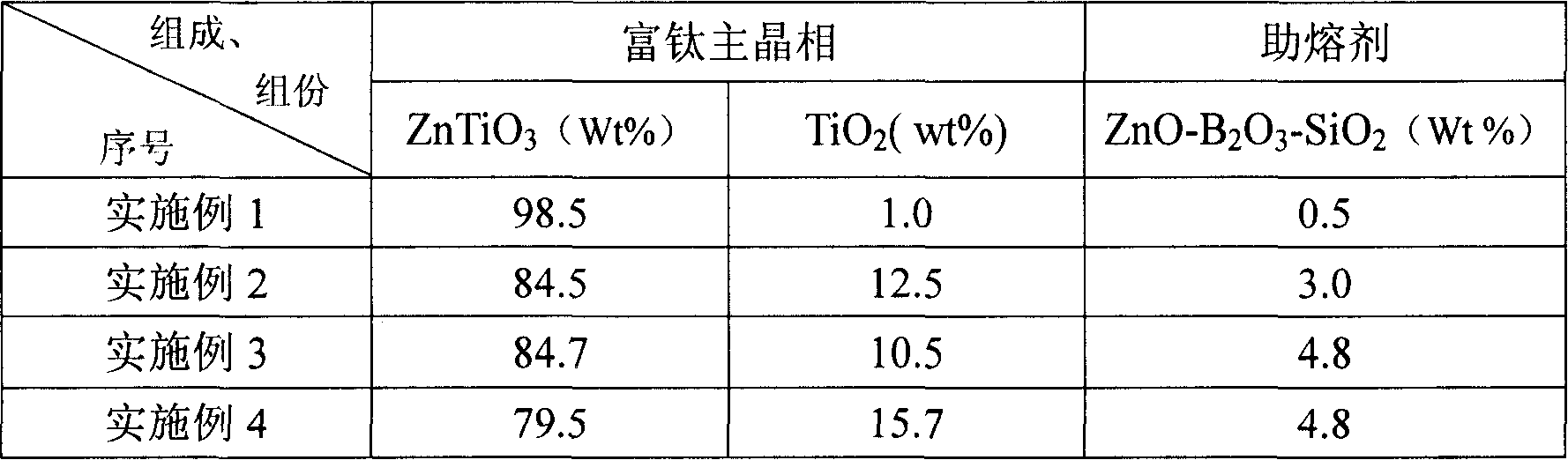

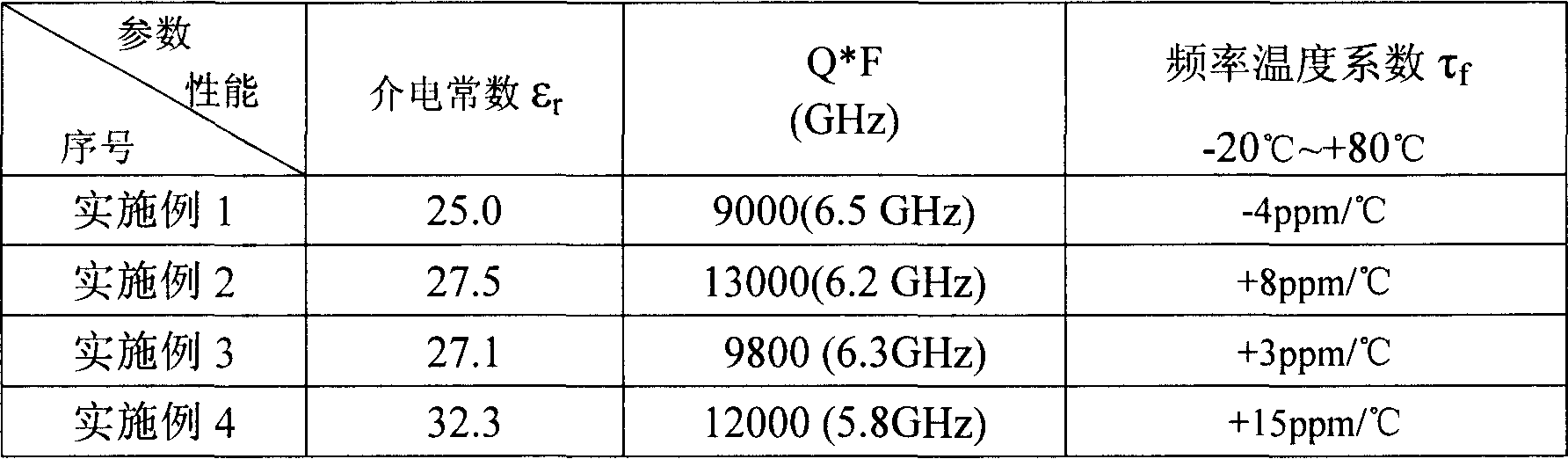

[0044] Below in conjunction with example the present invention is further described, the ZnO-TiO of each embodiment of the present invention 2 The formulation of low temperature co-fired ceramic materials is shown in Table 1.

[0045] Table 1

[0046]

[0047] Its preparation method is as follows:

[0048] 1. Titanium-rich main crystal phase ZnTiO 3 (TiO 2 ) is zinc oxide (ZnO), titanium dioxide (TiO 2 ) was mixed with deionized water into a homogeneous mixture in a polyurethane-lined vertical agitating ball mill according to the formula in Table 1, and the mixture was passed through a 120-mesh sieve and dried in a stainless steel bucket, and then the dry powder was pulverized into a uniform fine powder, loaded with Al 2 o 3 In a corundum crucible, calcined at 780°C for 2-4 hours, then pulverized in a vertical stirring ball mill, and dried for later use.

[0049] 2. Zinc borosilicate glass (ZnO-B 2 o 3 -SiO 2 ) is to use ZnO, B 2 o 3 , SiO 2 According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com