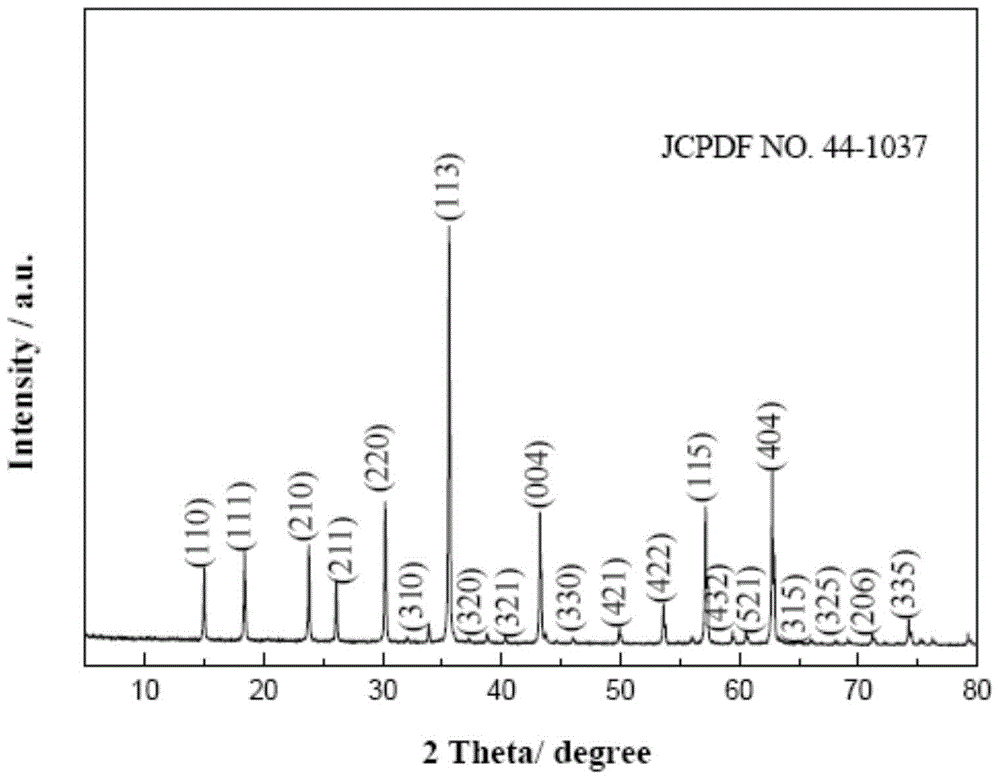

Lithium ion battery negative electrode material Li2ZnTi3O8 preparation method

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. Inexpensive, time- and energy-saving, resource-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Titanium dioxide (TiO 2 ), lithium carbonate (Li 2 CO 3 ), zinc acetate (Zn(CH 3 COO) 2 2H 2 O), the molten salt is prepared according to the molar ratio of 3:1:1:4, the molten salt is a mixture of NaCl and KCl, and the molar ratio of the two is 1:1;

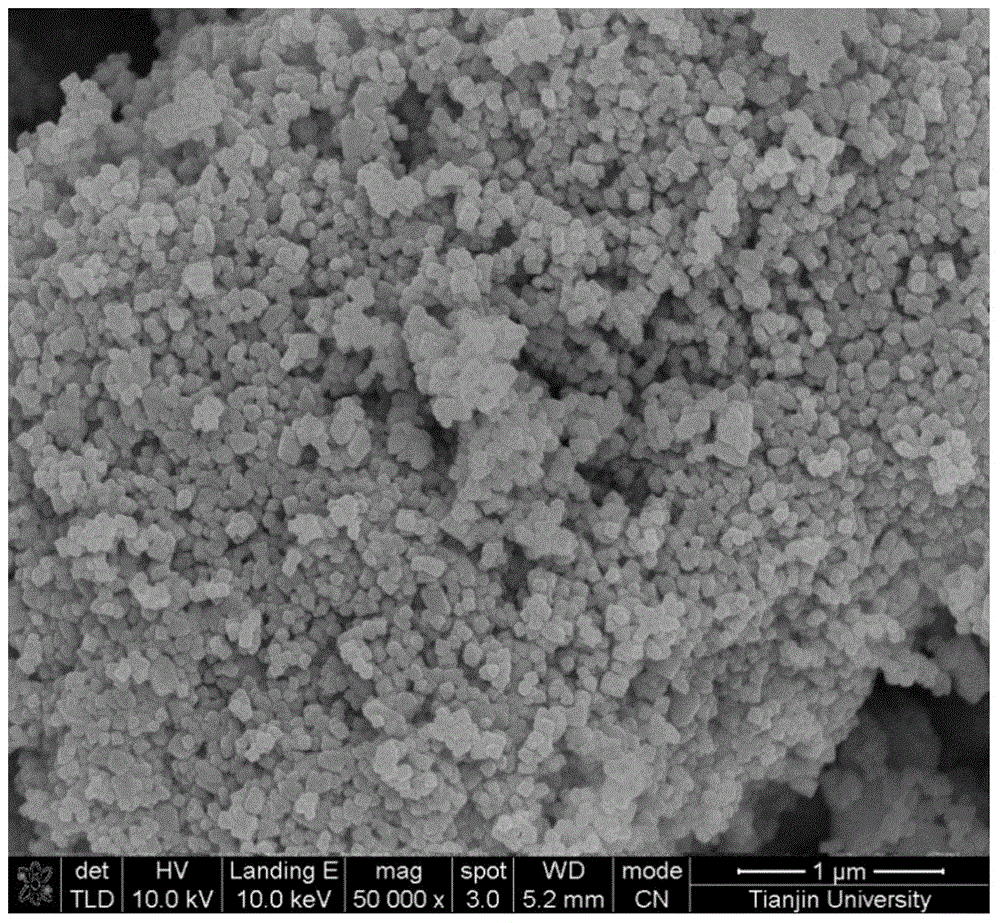

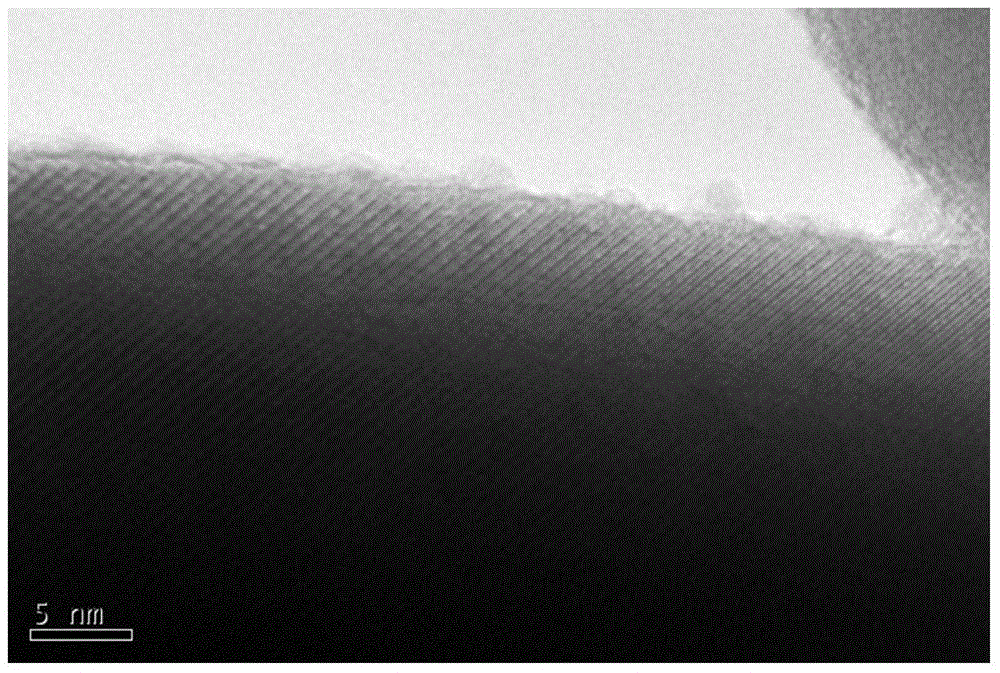

[0027] Put it in a high-energy ball mill tank (15 large balls and 30 small balls), add ethanol, the molar ratio of titanium dioxide to ethanol is = 1:30, and mill at 400r / min for 4 hours. Take it out, dry it in blast drying at 80 degrees Celsius for 24 hours, grind it and calcinate it in a muffle furnace at 800 degrees Celsius for 3 hours, wash it with deionized water three times after natural cooling, centrifuge, dry it, and grind it to obtain a lithium-ion battery Negative electrode material lithium zinc titanate.

[0028] The active material lithium zinc titanate, conductive agent (Super P), and binder (PVDF) were mixed in a mass ratio of 80:10:10, and coated on a copper sheet with a film applicator to form a 16u...

Embodiment 2

[0030] Titanium dioxide (TiO 2 ), lithium carbonate (Li 2 CO 3 ), zinc acetate (Zn(CH 3 COO) 2 2H 2 O), the molten salt is prepared according to the molar ratio of 3:1:1:3, and other process parameters are the same as in Example 1.

Embodiment 3

[0032] Titanium dioxide (TiO 2 ), lithium carbonate (Li 2 CO 3 ), zinc acetate (Zn(CH 3 COO) 2 2H 2 O), the molten salt is prepared according to the molar ratio of 3:1:1:2, and other process parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com