A kind of silicon carbon composite material and its preparation method and application

A silicon-carbon composite material and carbon content technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of restricting lithium ion migration rate, poor material rate performance, and reduced charge and discharge efficiency, and achieve good cycle stability. , good electrical conductivity, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

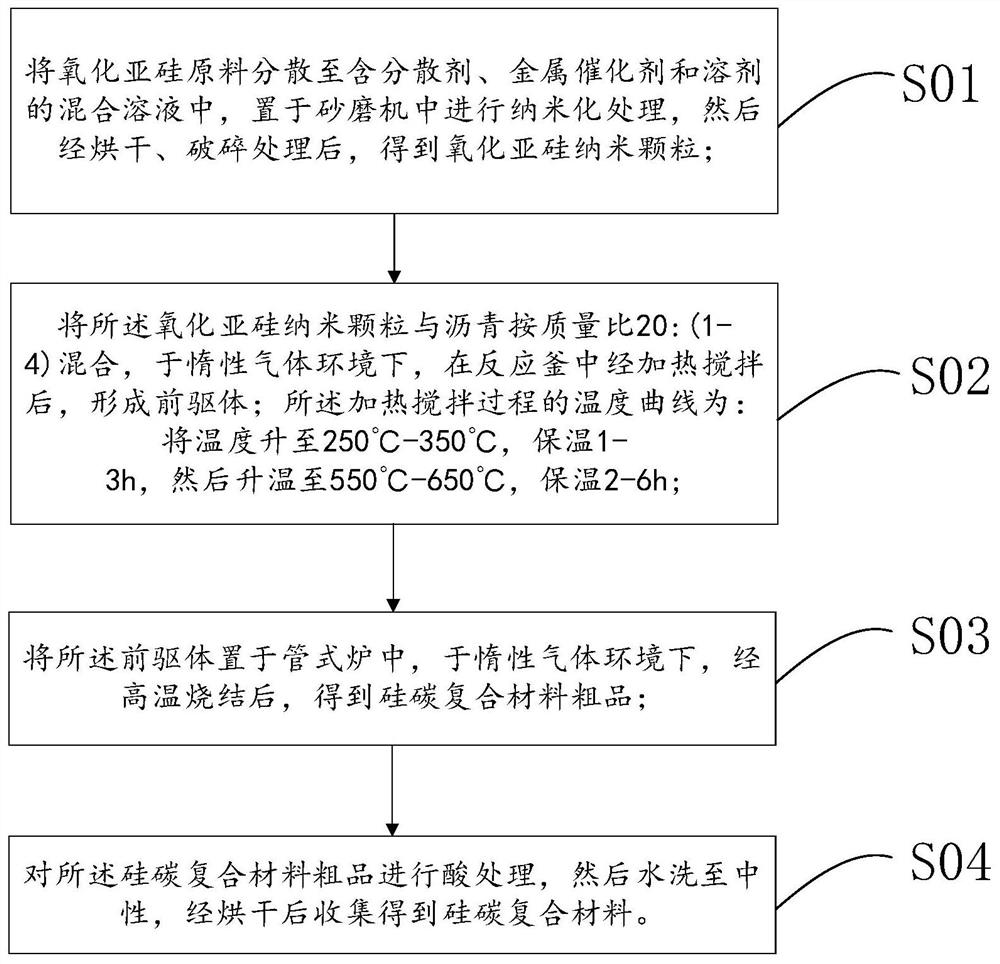

[0067] see figure 1 , In one embodiment of the present invention, a method for preparing a silicon-carbon composite material is provided, comprising the following steps:

[0068] S01. Disperse the silicon oxide raw material into a mixed solution containing a dispersant, a metal catalyst, and a solvent, place it in a sand mill for nano-processing, and then dry and crush it to obtain silicon oxide nanoparticles;

[0069] S02. Mix the silicon oxide nanoparticles and asphalt in a mass ratio of 20:(1-4), and form a precursor after heating and stirring in a reaction kettle under an inert gas environment; the temperature of the heating and stirring process The curve is: raise the temperature to 250°C-350°C, keep warm for 1-3h, then raise the temperature to 550°C-650°C, keep warm for 2-6h;

[0070] S03, placing the precursor in a tube furnace, and sintering at a high temperature in an inert gas environment to obtain a crude silicon-carbon composite material;

[0071] S04. Perform ac...

Embodiment 1

[0074] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0075] (1) Disperse 500g of the purchased silicon oxide raw material with a particle size of 1 μm in an ethanol solution in which 10g of polyvinylpyrrolidone and 3.26g of nickel nitrate hexahydrate are dissolved. The speed of the disperser is 1000rpm. After the dispersion is uniform, it is passed into a sand mill for grinding Until the particle size D90 is 300nm, the rotational speed of the sand mill is 3000rpm. The slurry obtained after sand grinding was dried and pulverized to obtain silicon oxide nanoparticles with a primary particle size of 300 nm.

[0076] (2) Add the collected silica nanoparticles and asphalt into the reactor at a mass ratio of 95:5, set the heating program at 250°C for 3 hours, 550°C for 3 hours, and knead the reactor at a stirring speed of 60rpm to obtain the precursor.

[0077] (3) The obtained precursor was sintered and disproportionated in a tube furnace u...

Embodiment 2

[0080] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0081] (1) Disperse 500g of purchased silicon oxide with a particle size of 20μm in a deionized aqueous solution in which 10g of polyvinylpyrrolidone and 15.48g of nickel nitrate hexahydrate are dissolved. The speed of the disperser is 1000rpm. After the dispersion is uniform, it is passed into a sand mill for grinding. Until the particle size D90 is 300nm, the rotational speed of the sand mill is 3000rpm. The slurry obtained after sand grinding was dried and pulverized to obtain silicon oxide nanoparticles with a primary particle size of 300 nm.

[0082] (2) Add the collected silica nanoparticles and asphalt into the reactor at a mass ratio of 80:20, set the heating program at 350°C for 3 hours, and at 650°C for 3 hours, and knead the reactor at a stirring speed of 120rpm to obtain the precursor.

[0083] (3) The obtained precursor was sintered and disproportionated in a tube furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com