Preparation method of zinc titanate and titanium dioxide composite nano material

A technology of composite nanomaterials and titanium dioxide, which is applied in the field of preparation of functional materials, can solve the problems of low solar energy utilization efficiency, and achieve the effects of easy operation and control, low preparation cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Slowly add the isopropanol solution with a concentration of 0.1mol / L zinc acetylacetonate into the isopropanol solution with a concentration of 0.1mol / L titanium acetylacetonate, dissolve and mix evenly in the alcohol solution, and carry out the mixed solution obtained. For the crosslinking reaction, the reaction temperature was 300° C., and the reaction time was 6 hours, wherein the molar ratio of zinc acetylacetonate to titanium acetylacetonate was 1:2. After the cross-linking reaction finishes, continue to carry out high-temperature reaction in the muffle furnace, the high-temperature reaction temperature is at 800 ℃, and the reaction time is 10h. After natural cooling, the target product is obtained.

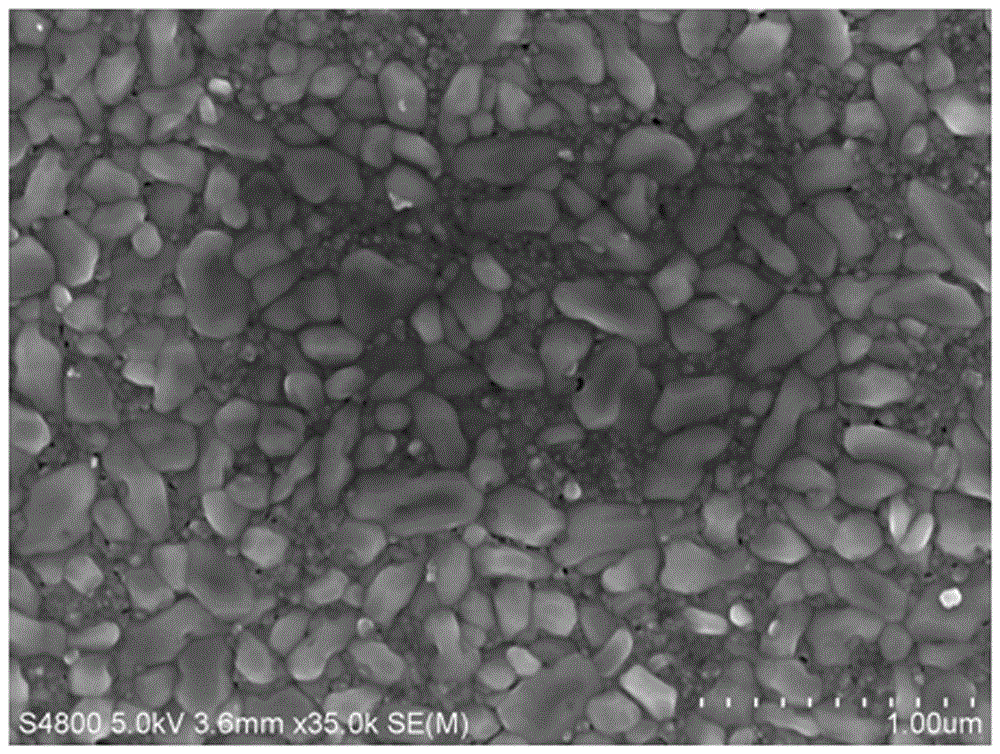

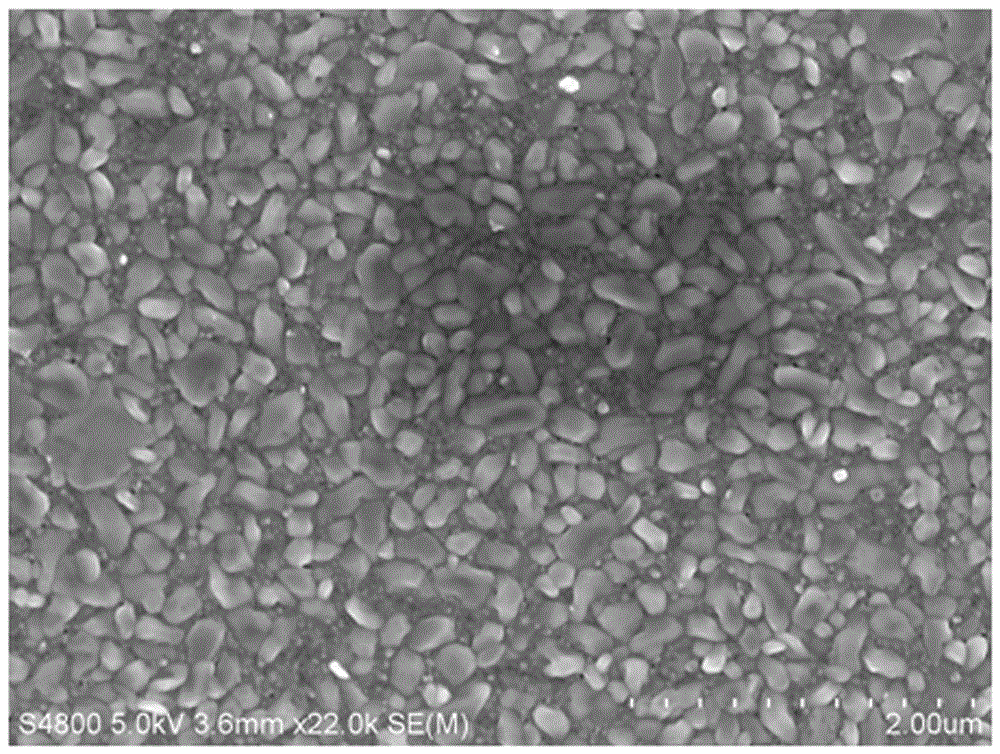

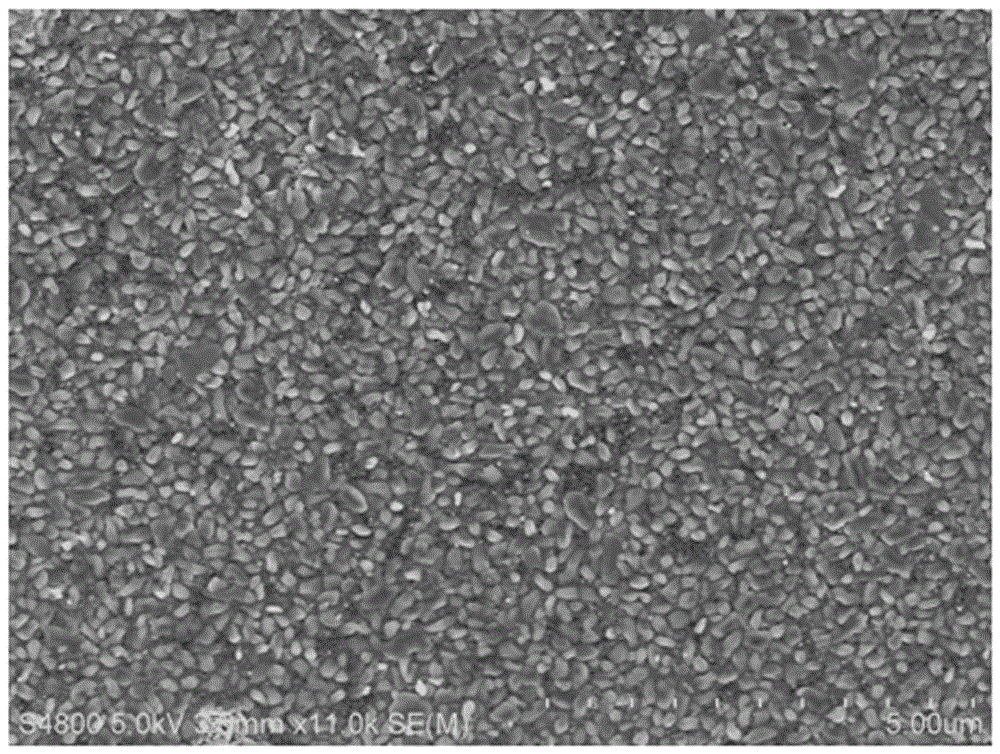

[0033] The particle size of the product is between 200-240nm, the band gap is 2.8eV, and the yield of the product is 99.5%. The product purity is 99.8%, impurity content: carbon is less than 0.2%. The prepared zinc titanate / titanium dioxide composite nanomaterial wa...

Embodiment 2

[0035] Slowly add the methanol solution with a concentration of 0.1mol / L zinc acetylacetonate into the methanol solution with a concentration of 0.1mol / L titanium acetylacetonate, dissolve and mix in the alcohol solution, and the obtained mixed solution undergoes cross-linking reaction. The temperature is 250° C., the reaction time is 8 hours, and the molar ratio of zinc acetylacetonate and titanium acetylacetonate is 1:2. After the cross-linking reaction is finished, continue to carry out high-temperature reaction in the muffle furnace, the high-temperature reaction temperature is at 1000 ° C, and the reaction time is 24h. After natural cooling, the target product is obtained.

[0036] The particle size of the product is between 210-250nm, the band gap is 2.75eV, and the yield of the product is 99.1%. The product purity is not less than 99.7%, and the impurity content: carbon is less than 0.3%. The prepared zinc titanate / titanium dioxide composite nanomaterial was used as a...

Embodiment 3

[0038]Slowly add the ethanol solution of zinc acetylacetonate with a concentration of 0.05mol / L to the ethanol solution of titanium acetylacetonate with a concentration of 0.05mol / L slowly, dissolve and mix well in the alcohol solution. The obtained mixed solution was subjected to cross-linking reaction, the reaction temperature was 400° C., and the reaction time was 2 hours, wherein the molar ratio of zinc acetylacetonate and titanium acetylacetonate was 1:2. After the cross-linking reaction is finished, continue to carry out high-temperature reaction in the muffle furnace, the high-temperature reaction temperature is at 1000 ° C, and the reaction time is 24h. After natural cooling, the target product is obtained.

[0039] The particle size of the product is between 240-280nm, the band gap is 2.72eV, and the yield of the product is 99.2%. The product purity is not less than 99.6%, and the impurity content: carbon is less than 0.4%. The prepared zinc titanate / titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com