Method for preparing carbon-coated lithium zinc titanate nanoribbon

A technology of carbon-coated zinc titanate and nanobelts, which is applied to electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of large influence of molecular sieves and poor selectivity, and achieve good reproducibility, less agglomeration, and dispersion uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

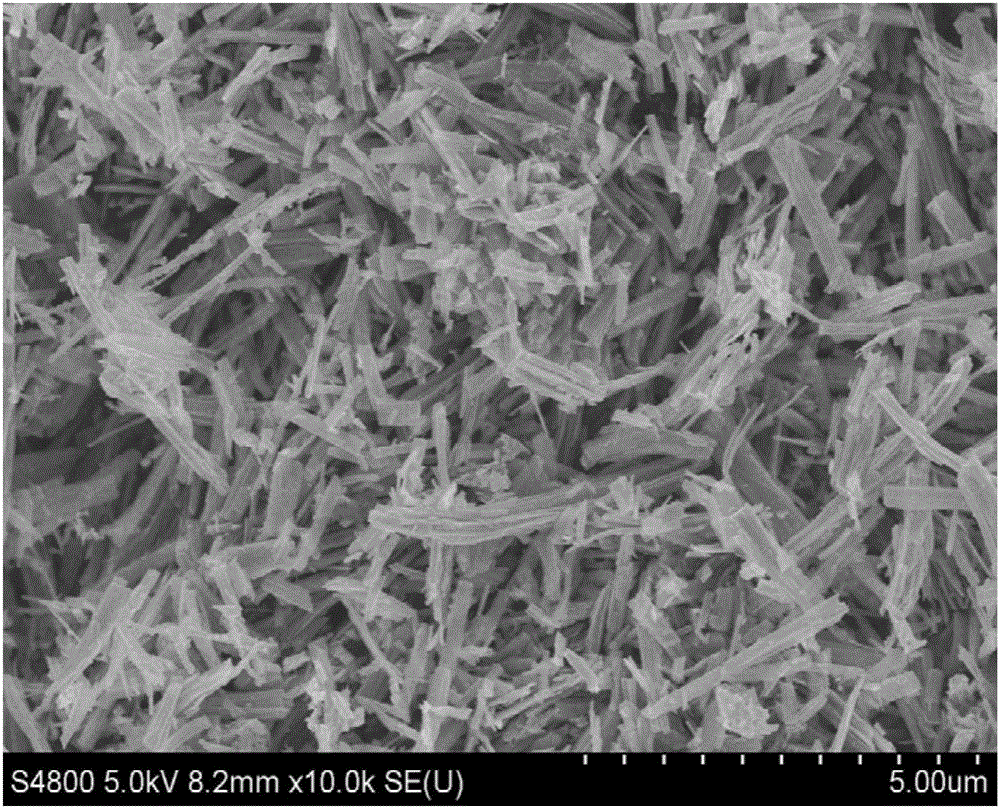

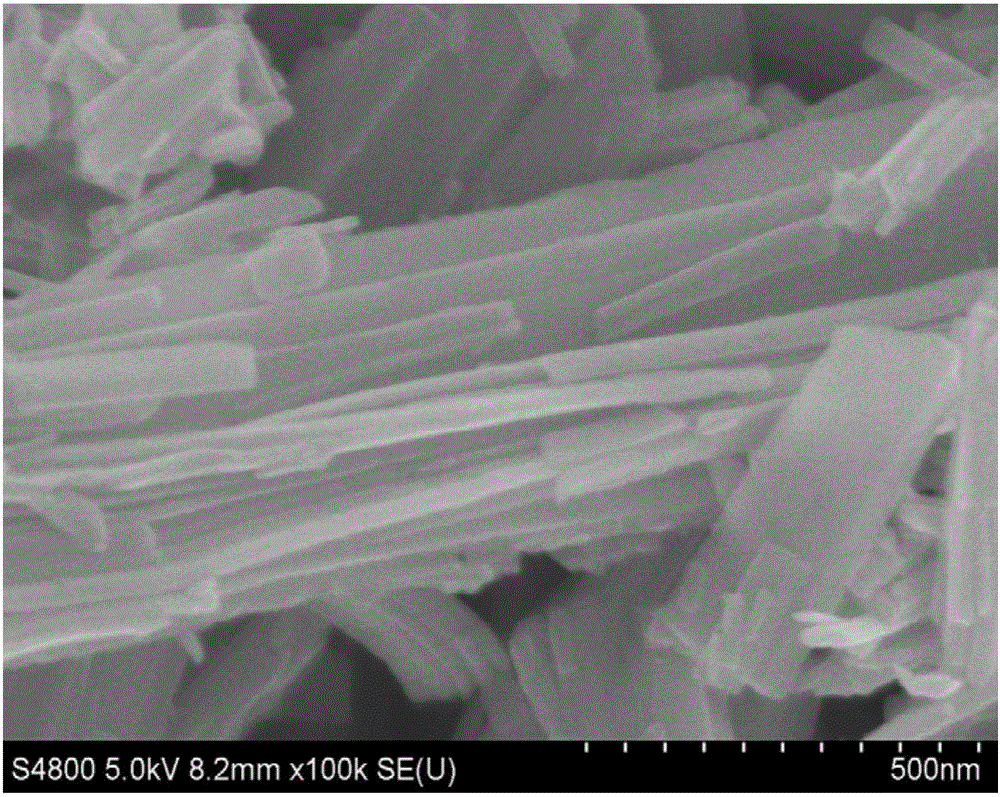

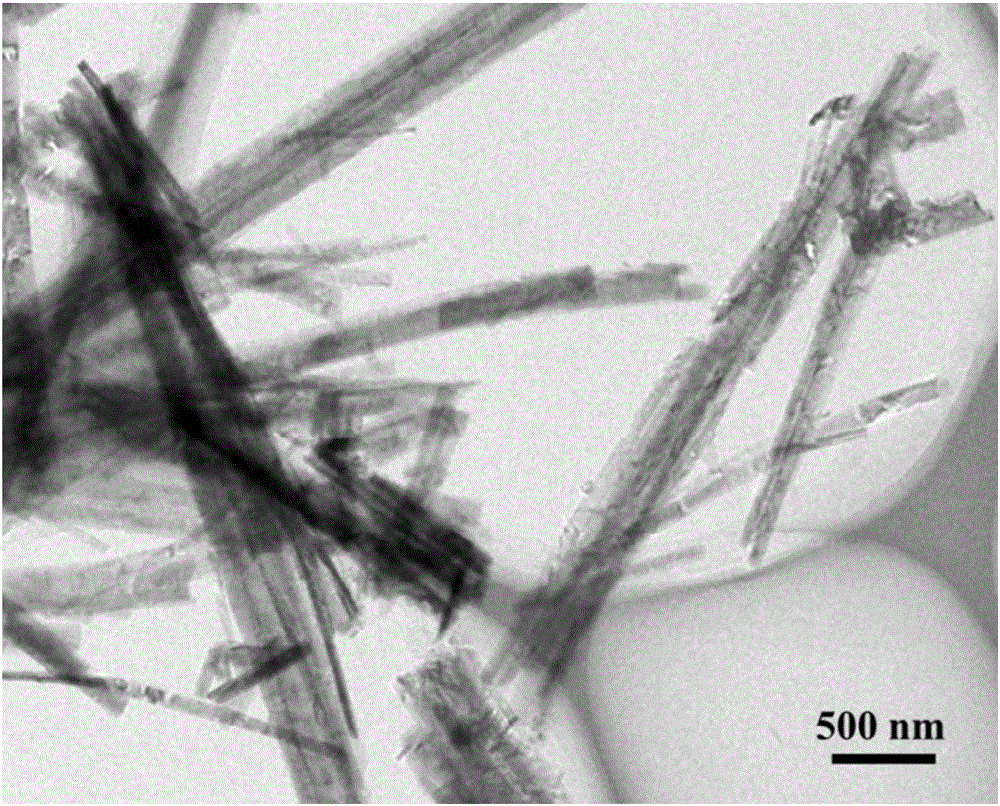

[0055] A preparation method of carbon-coated zinc lithium titanate nanobelt, comprising the following steps:

[0056] 1) TiO 2 The particles were placed in a strongly alkaline 10M NaOH solution, heated at 170°C for 1 day, and the TiO 2 The mass / volume ratio of particles to NaOH solution is 0.1g / 20ml;

[0057] 2) with 0.1M acid (such as HCl or HNO 3 ) washing the hydrothermal product obtained in step 1) to weak acidity, then stirring with 0.05M hydrochloric acid for 3 hours and then centrifuging to obtain a precursor (hydrogenated titanate nanoribbons);

[0058] 3) Weigh 0.3g of the precursor obtained in step 2), mix the above-mentioned precursor with zinc acetate and lithium hydroxide, and in terms of titanium, lithium and zinc, the molar ratio between them is Ti:Li:Zn =3:2:1, and 0.049g of glucose was added, 25mL of ethanol was added to the above mixture, stirred until gelatinous, and dried in an air atmosphere at 70°C;

[0059] 4) After the dried material is ground evenl...

Embodiment 2

[0064] A preparation method of lithium zinc titanate and carbon composite, comprising the following steps:

[0065] 1) TiO 2 The particles were placed in a strongly alkaline 10M NaOH solution, heated at 170°C for 1 day, and the TiO 2 The mass / volume ratio of particles to NaOH solution is 0.5g / 20ml;

[0066] 2) with 0.1M acid (such as HCl or HNO 3 ) washing the hydrothermal product obtained in step 1) to weak acidity, then stirring with 0.05M hydrochloric acid for 3 hours and then centrifuging to obtain a precursor (hydrogenated titanate nanoribbons);

[0067] 3) Weigh 0.3g of the precursor obtained in step 2), according to the stoichiometric ratio of titanium, lithium and zinc, mix the above precursor with zinc acetate and lithium hydroxide according to Ti:Li:Zn=3:2 : 1 stoichiometric ratio mixing, and adding 0.099g of glucose, adding 25mL of ethanol to the above mixture, stirring until gelatinous, and drying at 70°C in an air atmosphere;

[0068] 4) After the dried materi...

Embodiment 3

[0071] A preparation method of lithium zinc titanate and carbon composite, comprising the following steps:

[0072] 1) TiO 2 The particles were placed in a strongly alkaline 10M NaOH solution, heated at 170°C for 1 day, and the TiO 2 The mass / volume ratio of particles to NaOH solution is 1g / 20ml;

[0073] 2) with 0.1M acid (such as HCl or HNO 3 ) washing the hydrothermal product obtained in step 1) to weak acidity, then stirring with 0.05M hydrochloric acid for 3 hours and then centrifuging to obtain a precursor (hydrogenated titanate nanoribbons);

[0074] 3) Weigh 0.3g of the precursor obtained in step 2), according to the stoichiometric ratio of titanium, lithium and zinc, mix the above precursor with zinc acetate and lithium hydroxide according to Ti:Li:Zn=3:2 : 1 stoichiometric ratio mixing, and adding 0.198g of glucose, adding 25mL of ethanol to the above mixture, stirring until gelatinous, and drying at 70°C in an air atmosphere;

[0075] 4) After the dried material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com