Combined treatment process of synthesis pharmaceutical wastewater

A technology for treating process and waste water, which is applied in the field of water, sewage or sludge treatment and waste water. It can solve the problems of long reaction time, large chemical reagents, large amount of suspended solids, etc., and achieve the effect of improving clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

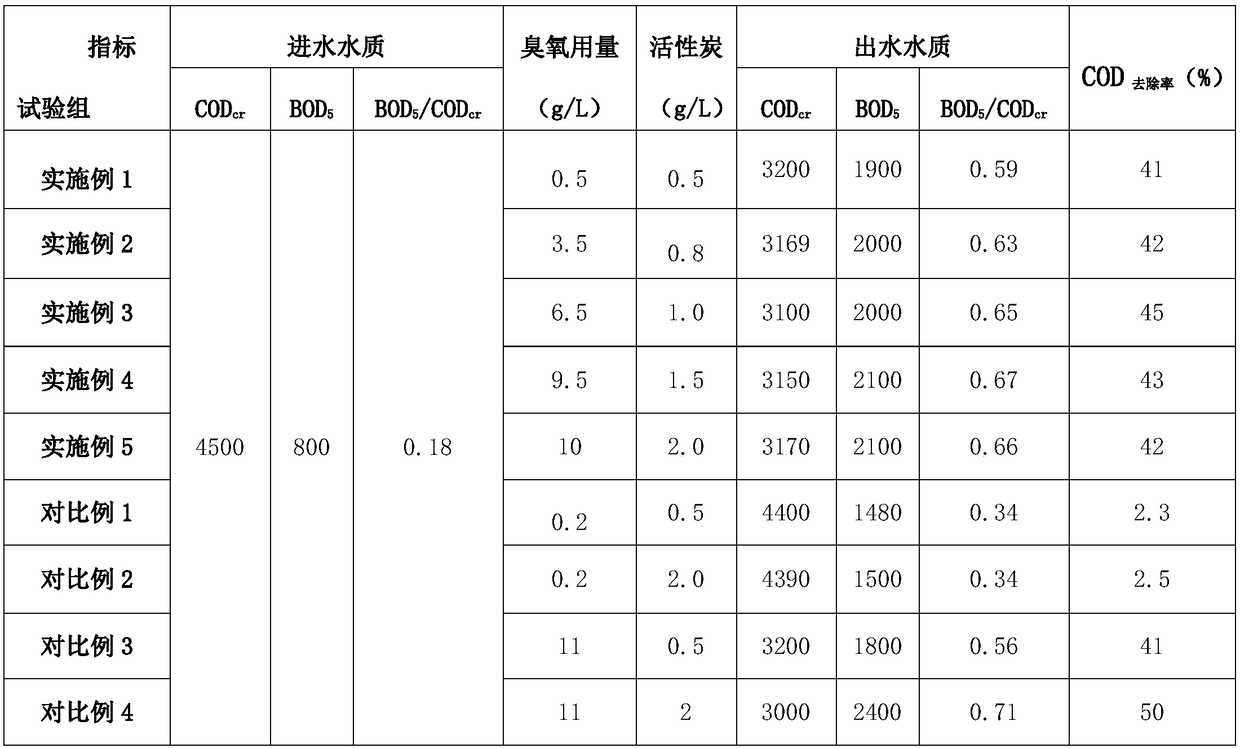

Examples

Embodiment

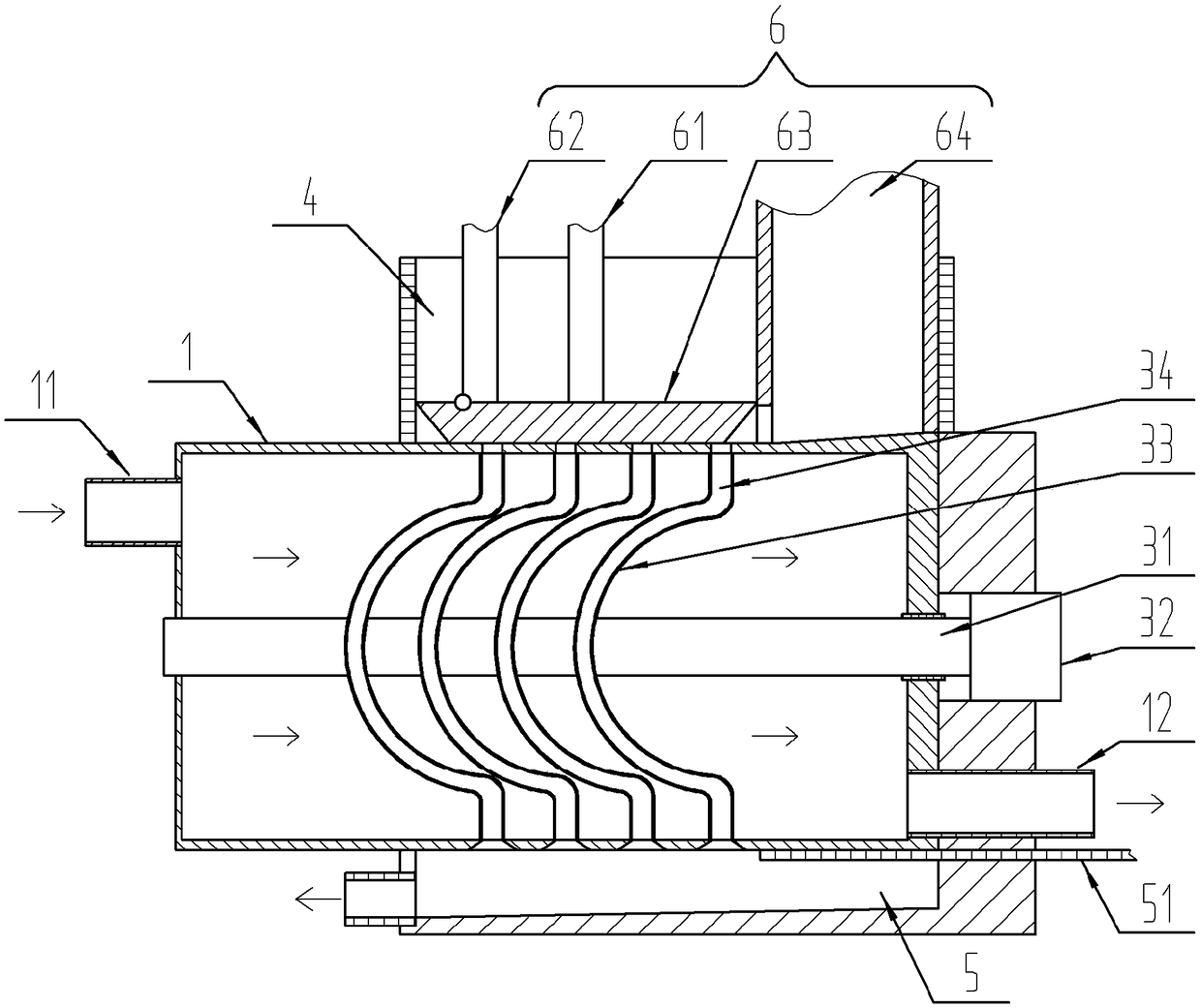

[0024] A combined treatment process for synthetic drug wastewater, comprising a pretreatment step and a biochemical treatment step, the pretreatment step comprising:

[0025] (1) Remove suspended matter through a filter device to remove suspended matter in wastewater;

[0026] (2) Recrystallize the waste water obtained in step (1), the number of times of recrystallization is twice, the heating temperature for the first recrystallization is 120-150°C, and the heating temperature for the second recrystallization is 200-250°C , the heating time of the first recrystallization and the second recrystallization is 30-60min, the cooling temperature of the first recrystallization and the second recrystallization is -10-5 ℃; during the cooling process of recrystallization, Throwing activated carbon into the waste water; the gas volatilized during the heating process of the step (2) is cooled, and then passed into the waste water treated in the step (2).

[0027] (3) The waste water tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com