Polymer dispersed liquid crystal material and manufacturing method thereof

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of low adhesion, non-brightness of thin notes, and low contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

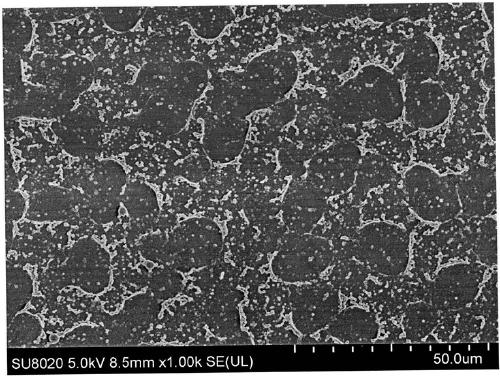

Image

Examples

Embodiment 1

[0034] This embodiment provides a polymer dispersed liquid crystal material, which comprises the following components by weight: cholesteric liquid crystal (78%), photocurable monomer (20%), photoinitiator ( 0.4%), spacer particles (0.5%), solvent (1%), coupling agent (0.1%).

[0035] The birefringence Δn≧0.16 of the cholesteric liquid crystal.

[0036] The photocurable monomer comprises 4-hydroxybutyl vinyl ether (12%), ethoxylated trimethylolpropane triacrylate (8%), wherein the 4-hydroxybutyl vinyl ether structural formula is as follows:

[0037]

[0038] The structural formula of the ethoxylated trimethylolpropane triacrylate is as follows:

[0039]

[0040] The photoinitiator includes 4-(phenylthio)phenyldiphenylsulfonium hexafluorophosphate (0.1%), 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (0.3%) ), wherein the 4-(phenylthio)phenyldiphenylsulfonium hexafluorophosphate structural formula is as follows:

[0041]

[0042] The structural formula of the 2,4,6...

Embodiment 2

[0056] This embodiment provides a polymer dispersed liquid crystal material, which comprises the following components by weight: 70% cholesteric liquid crystal, photocurable monomer (23%), 0.7% photoinitiator, Spacer particles 1%, solvent 5%, coupling agent 0.3%.

[0057] The birefringence Δn≧0.16 of the cholesteric liquid crystal.

[0058] The photocurable monomer comprises cyclotrimethylolpropane formal acrylate (15%), triethylene glycol divinyl ether (6%), trimethylpropane trimethacrylate (2%), Wherein said cyclotrimethylolpropane methylal acrylate structural formula is as follows:

[0059]

[0060] Described triethylene glycol divinyl ether structural formula is as follows:

[0061]

[0062] Described trimethylpropane trimethacrylate structural formula is as follows:

[0063]

[0064] The photoinitiator includes 0.2% of 4-isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate, 0.5% of ethyl 2,4,6-trimethylbenzoylphenylphosphonate , wherein the structural for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com