Novel pulverized coal high-pressure forming device

A high-pressure forming, pulverized coal technology, used in presses, presses using rotating pressure components, grain processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0019] In the present invention, for the convenience of description, the relative positional relationship of each component is based on the description attached figure 1 The layout method is described, such as: up, down, left, right, front, back and other positional relationships are based on the attached figure 1 determined by the layout direction.

[0020] Below in conjunction with embodiment and accompanying drawing, this utility model is further described:

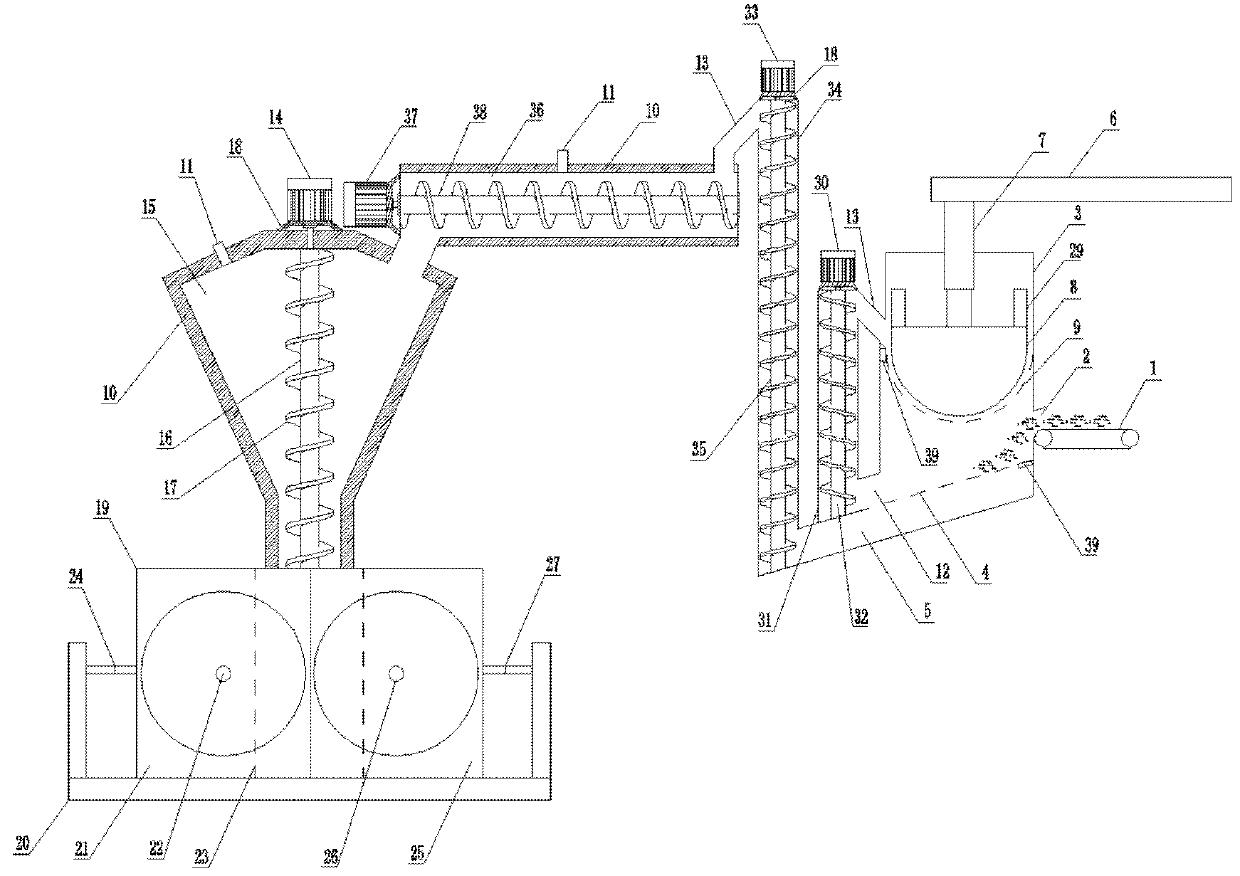

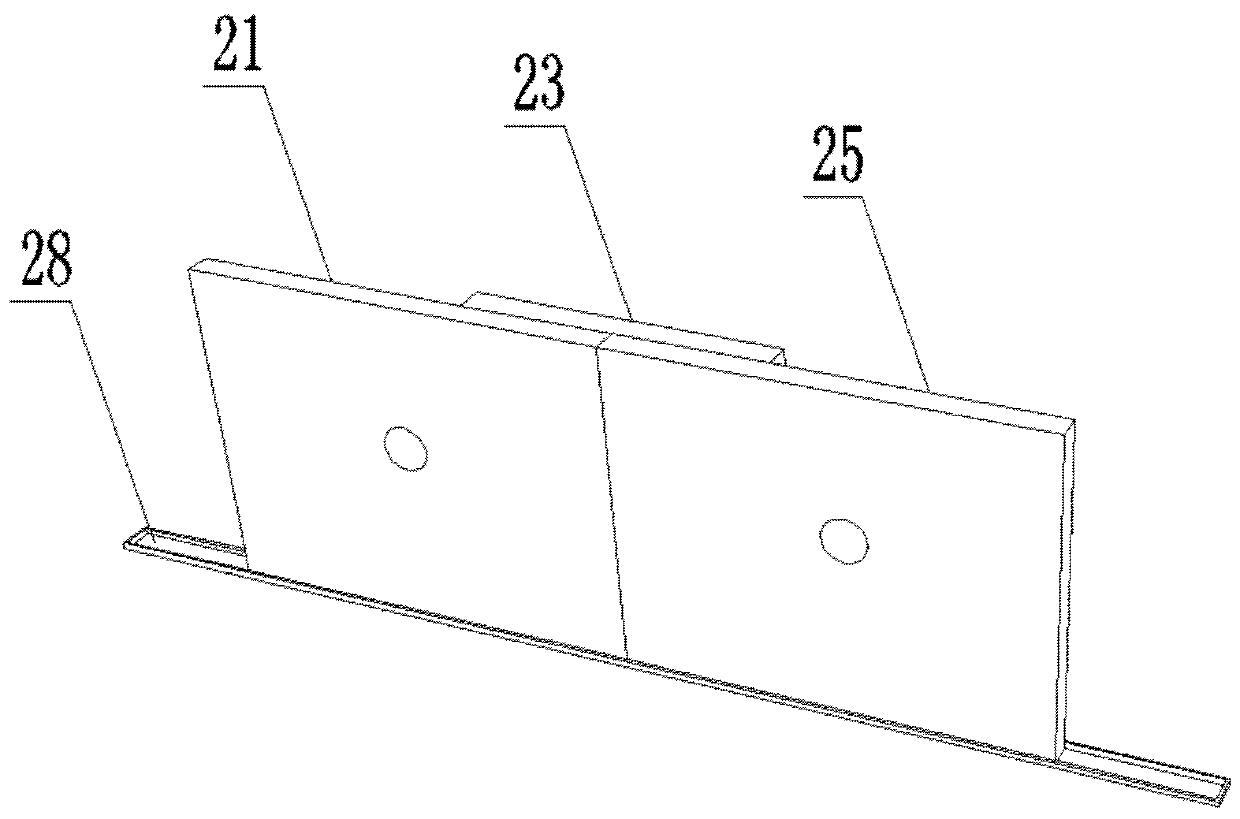

[0021] Such as figure 1 , 2As shown, a new type of pulverized coal high-pressure forming device includes a first conveying device 1, a screening box 3 with a feed inlet 2 at the lower right side, a first screen 4, a feeding channel 5, a first lifting device, The second lifting device, the support plate 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com