6-series aluminum alloy and machining method thereof

A processing method and aluminum alloy technology, which is applied in the field of non-ferrous metal processing, can solve problems such as coarseness and inability to cover up structural defects, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

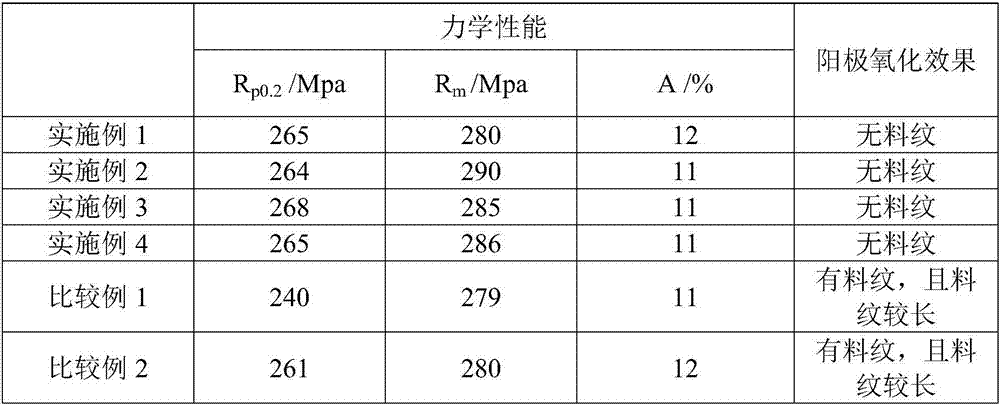

Examples

Embodiment 1

[0048] A 6-series aluminum alloy prepared from raw materials comprising the following components:

[0049] Mg: 0.8wt%, Si: 0.6wt%, Mn: 0.02wt%, Ti: 0.02wt%, Fe: 0.08wt%, Cu: 0.02wt%, Cr: 0.005wt.%, the rest is Al and in production and processing unavoidable impurities.

[0050] The processing method of above-mentioned 6 series aluminum alloy comprises the following steps:

[0051] The ingot was homogenized annealed at 530 °C for the first time for 8 h, then cooled to 490 °C for hot rolling, the pass processing rate was 10%, the final hot rolling thickness was 8 mm, and then cold rolling and solid solution Treat the second heat preservation at 550 °C for 30 seconds, and then perform aging treatment at 180 °C for the third time heat preservation for 7 h.

Embodiment 2

[0053] A 6-series aluminum alloy, the composition of which is: Mg 0.7 wt%, Si 0.7 wt%, Mn 0.01 wt%, Ti 0.01 wt.%, Fe 0.07 wt.%, Cu 0.01 wt.%, Cr0.006 wt% , the balance being Al.

[0054] The processing method of above-mentioned 6 series aluminum alloy comprises the following steps:

[0055] The ingot was homogenized annealed at 550 °C for 4 h, then cooled to 500 °C for hot rolling, with a pass processing rate of 15%, hot final rolling thickness of 6 mm, and then cold rolling and solution treatment at 565 °C C for 40 seconds, then aging treatment at 175°C for 8 h.

Embodiment 3

[0057] A 6-series aluminum alloy, comprising:

[0058] Mg 1.0 wt%, Si 0.8 wt%, Mn 0.04 wt%, Ti 0.03 wt%, Fe 0.1 wt%, Cu0.03 wt%, Cr0.005wt%, the rest is Al. Its processing method comprises the following steps: carry out homogenization annealing to ingot 570 ℃ of insulation 5 h, then cool to 400 ℃ and carry out hot rolling, pass processing rate is 12%, hot final rolling thickness is 10 mm, then cold Rolling and solution treatment at 530°C for 10 seconds, then aging treatment at 160°C for 10h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com