Water sealing fire retardance explosion venting device

A water-sealing fire prevention and explosion venting technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of reducing the safety protection effect, increasing the load, affecting the safe production of coal mines, etc., to prevent instability and severe fluctuations, improve safety and reliability, and achieve automatic monitoring and water replenishment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

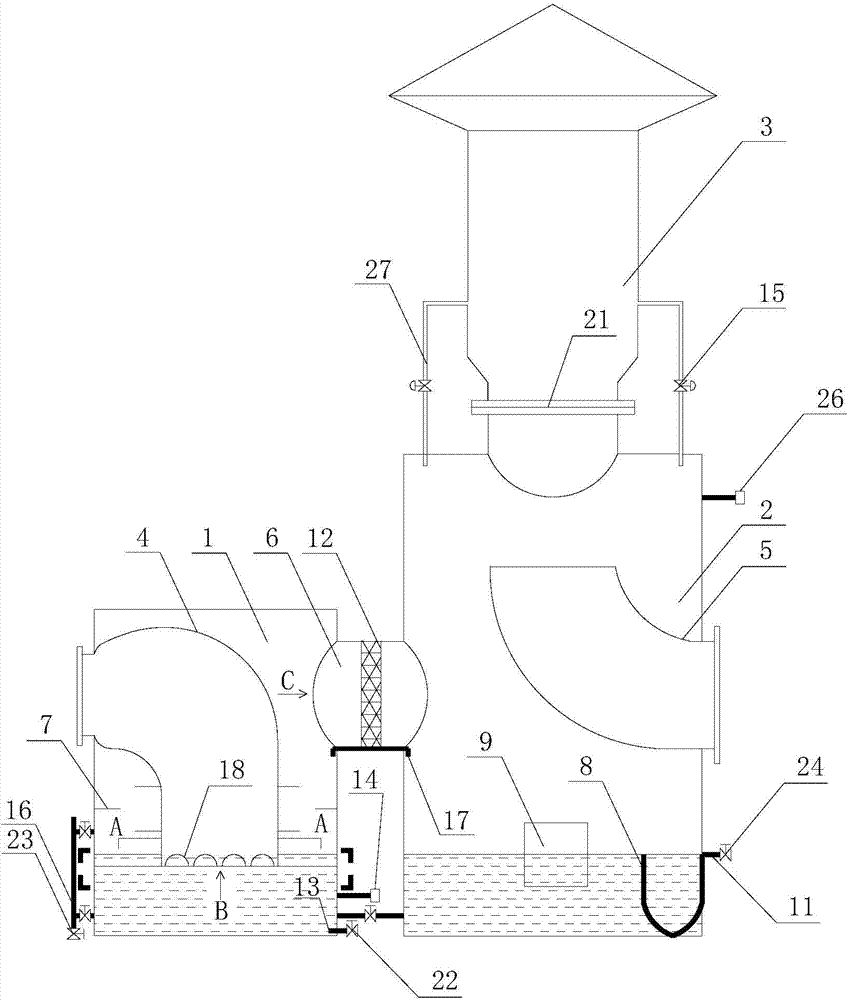

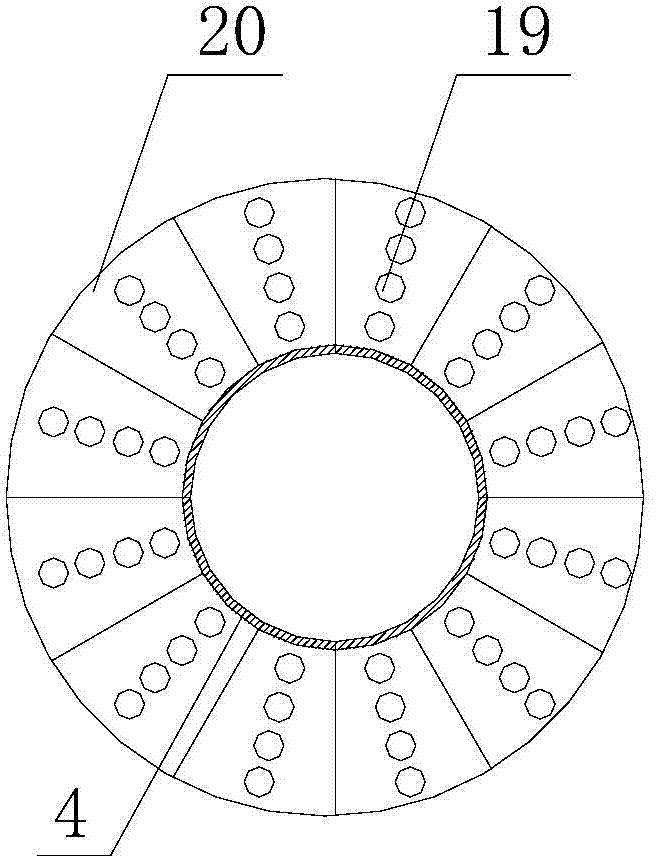

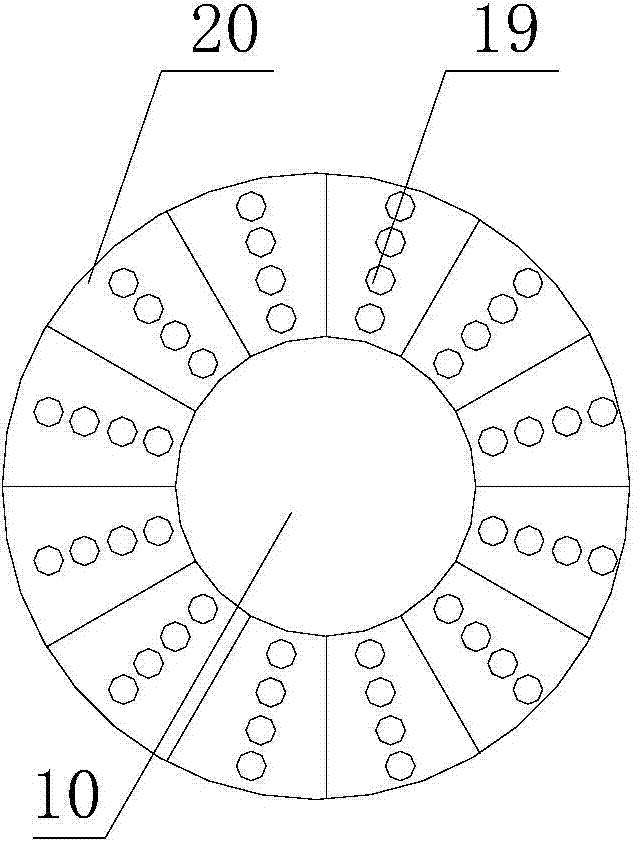

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, as Figures 1 to 5 Shown: the water-sealed fire arresting and explosion venting device of the present embodiment includes a flame arrester and an explosion venting device; the flame arrester includes a fire arresting barrel body 1, an air inlet pipe 4, an air outlet pipe 6 and a water filtering metal ring net 7, and the One end of the air intake pipe 4 is located outside the fire retardant barrel body 1, and the other end extends into the fire retardant barrel body 1 and is inserted below the liquid level of the sealing water. Outside; the explosion venting device includes an explosion venting barrel body 2 and an exhaust pipe 5 and an explosion venting pipe 3 communicating with the explosion venting barrel body 2. Explosion-venting barrels 2 communicate with each other, and the explosion-venting pipe 3 is provided with a burst disc 21; the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com