Preparation method of ester group-containing azo disperse dye

A technology of disperse dyes and ester-based azo, which is applied in the direction of azo dyes, monoazo dyes, organic dyes, etc. It can solve the problems of color deterioration, affect product quality, and reduce the purity of filter cakes, so as to reduce the content of organic matter , Reduce the content of organic pollutants, improve the yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

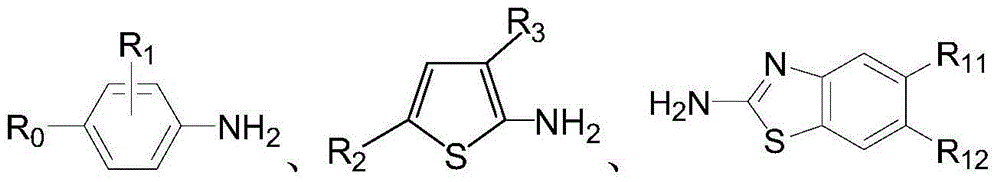

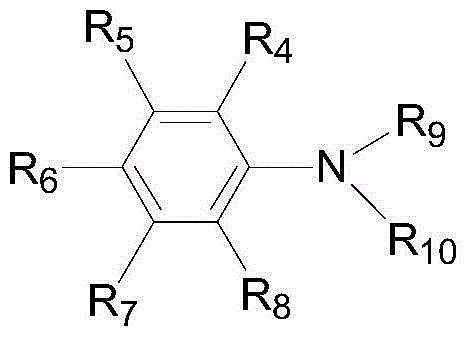

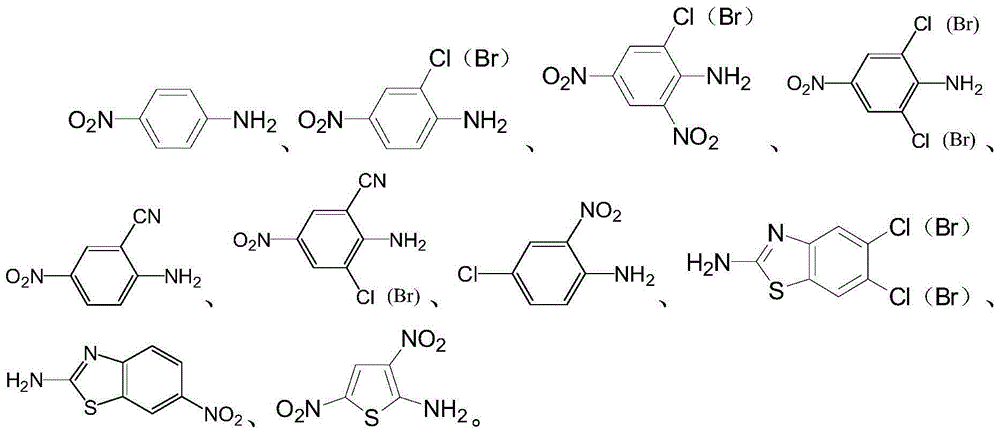

Method used

Image

Examples

Embodiment 1

[0039] Put 2000kg of 98% sulfuric acid (mass percentage concentration, the same below) and 28% (mass percentage concentration, the solvent is sulfuric acid, the same below) nitrosyl sulfuric acid 2370kg in sequence in the diazo kettle, turn on the frozen brine to stir and cool down, and slowly put in 900kg of o-chloro-p-nitroaniline, after adding, keep warm at below 5°C until the reaction is complete, and set aside;

[0040]Add 30000kg of ice water to the coupling kettle, add 10kg evenly, and 30kg of urea, then add the above-mentioned diazo solution for dilution, control the temperature at 0-5°C, and slowly add 1710kg of N, N-diacetoxyethyl- Acetaminoaniline, keep warm until the end point is qualified, start to add ammonia solution (mass percentage concentration is 15%), adjust the pH value of the system to 5.0-6.0, then heat up to 60-65 ° C, stir for 1 hour, and wait for the dye to turn After the crystal enters the filter press and presses and washes to neutrality, the filter...

Embodiment 2

[0043] Put 1000kg of 98% sulfuric acid and 3150kg of 28% nitrosylsulfuric acid into the diazo kettle in turn, turn on the frozen brine to stir and cool down, slowly put in 900kg of p-nitroaniline, after adding, keep it warm until the reaction is complete under 5°C, and set aside;

[0044] Add 15,000kg of bottom water to the coupling kettle, add 25kg of Pingpingjia and 735kg of N, N-diacetoxyethyl-m-acetaniline, after beating for 2 hours, dig out crushed ice to cool down, then add the above-mentioned diazonium solution, and add 0 to 5 Incubate at ℃ for 6 hours, after the detection end point is qualified, start to add ammonia solution (mass percentage concentration is 18%) to adjust the pH value of the system to 6.0-7.0, then raise the temperature to 65-70 ℃, stir for 1 hour and wait for the dye to crystallize before proceeding Filter press filter, wash to neutrality, obtain 74 scarlet disperse dyes filter cake, mother liquor water is used for the preparation of ammonium sulfate ...

Embodiment 3

[0047] Put 600kg of 98% sulfuric acid and 200kg of 85% phosphoric acid in the diazo kettle in turn, start stirring, put in 200kg of 2-amino-3,5-dinitrothiophene, and after beating for 4 hours, turn on the frozen brine, cool down to 0°C, and start Add 520kg of 28% nitrous sulfuric acid dropwise, after the addition is complete, keep it warm until the reaction is complete under 5°C, and set aside;

[0048] Add 6000kg of bottom water, 800kg of 98% sulfuric acid to the coupling kettle, then add 10kg of AEO-9 emulsifier and 300kg of N, N-diacetoxyethylaniline, beat for 20min, throw ice to cool down, add the above-mentioned diazo solution, add After the temperature is kept at 0-5°C for 3 hours, after the detection end point is qualified, start to add aqueous ammonia solution (10% by mass percentage) to adjust the pH value of the system to 5.5-6.5, then heat up to 55-60°C, stir and crystallize for 1 hour. After the dye is crystallized, enter the filter press and wash to neutrality to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com