A non-cleaning anode plate and wet electrostatic precipitator

A wet electrostatic precipitator and anode plate technology, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems that the electric field cannot operate stably and efficiently, the removal efficiency is not ideal, and the discharge phenomenon of the cathode line is aggravated. Less treatment capacity, saving process water, alleviating the effect of chimney rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

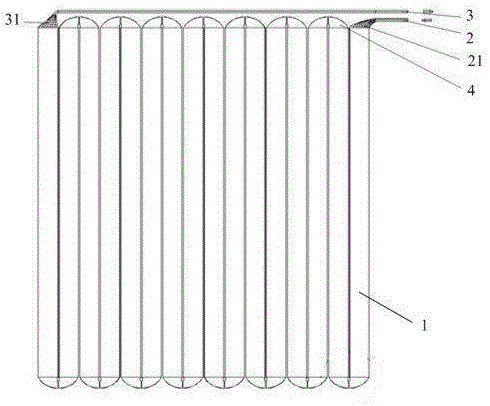

[0031] Such as figure 1 As shown, the no-clean anode plate in this embodiment takes an anode plate row as an example, this anode plate row includes 16 anode plate units 1, and the upper end of the rightmost anode plate unit 1 in the figure is the water inlet end of the anode plate row , which is connected to the water inlet 2 of the cooling water pipeline, and a connecting piece 21 is arranged at the joint. Connectors 31 are provided at each location, and connecting elbows 4 are provided between the free ends of every two adjacent anode plate units 1 for connecting the hollow structures of two adjacent anode plate units 1 .

[0032] Generally, the material of the anode plate unit 1 can be binocular stainless steel, 316L, conductive glass fiber reinforced plastics, composite anti-corrosion materials, polymer materials and the like. In this embodiment, 316L stainless steel is taken as an example, and a hollow anode plate unit 1 is formed by four steel plates 5, which is a flat ...

Embodiment 2

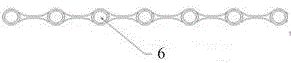

[0035] The anode plate unit 1 of the present embodiment is a diaphragm type, such as image 3As shown, the steel pipe 6 is installed in an approximately circular place, and the cooling water is passed through the steel pipe 6, the cooling water flow area is reduced, and the power consumption of the circulating water pump is reduced; the diaphragm is equivalent to a fin, which increases the heat exchange area, The heat exchange effect has been further improved; the thickness of the thinnest part of the diaphragm is very small, and the fit is relatively tight, which increases the rigidity of the anode plate and has a long service life.

[0036] The wet electrostatic precipitator provided by the present invention includes a housing with a cavity inside, and an anode plate and a cathode system are arranged in the housing, wherein: the anode plate is a non-cleaning anode plate as described in the above embodiment, and the anode plate and the cathode system An electric field is form...

Embodiment 3

[0038] Such as Figure 4 As shown, the electrostatic precipitator of this embodiment includes a housing, the inside of the housing is a cavity, and the housing is provided with an anode plate and a cathode system 8, wherein: the anode plate is the non-cleaning anode plate described in the above embodiment, here No need to go into details, after the cathode system 8 is energized, an electric field is generated between the cathode system 8 and the anode plate, and the dust is negatively charged in the electric field, and then is adsorbed onto the anode plate. The flue gas from the desulfurization absorption tower enters the interior of the electrostatic precipitator and flows through the electric field space. The gas flow direction is parallel to the anode plate and perpendicular to the cathode line in the cathode system 8. The liquid droplets and dust are collected and attached to the surface of the anode plate after being charged. The heat exchange reduces the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com