Technology for making aginomoto from rice

A rice and monosodium glutamate technology, applied in the biological field, can solve the problems of large steam consumption and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

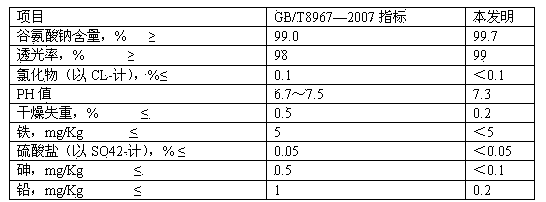

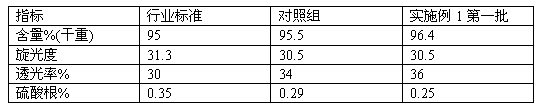

Examples

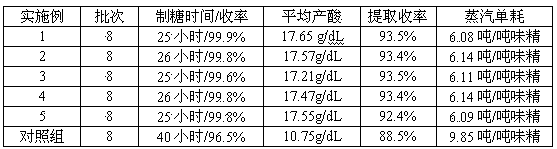

Embodiment 1

[0027] A kind of rice preparation monosodium glutamate process step is as follows:

[0028] (1) Wash the rice once, drain the rice water, soak in water, the water level should be 25 cm higher than the rice layer during the soaking process, soak for 2 hours; add the soaked rice and soaked rice water into the mill to refine the fineness More than 60 mesh, adjust the concentration of rice milk to 18 Baume, adjust the pH to 5.8 with calcium chloride, and increase the high-temperature α-amylase according to the ratio of adding 7 μg of high-temperature α-amylase to 1 g of rice; add the rice milk after adding high-temperature α-amylase Heating with a continuous injector, the heating temperature is controlled at 107°C, and the heated rice slurry is placed in a maintenance tank at 97°C for 45 minutes; the rice slurry is filtered with a plate frame at a filtration temperature of 68°C, and the rice dregs are filtered for later use. Add 90 μg of glucoamylase to 1 g of rice to increase th...

Embodiment 2

[0036] Experiments were carried out using the same process parameters as in Example 1, except that the ratio of the fermentation medium used was 200 ml / L of rice protein hydrolyzate, i.e. aminopeptide nitrogen 1.8 g / L, soybean oil: 1.0 g / L, rice enzyme Sugar solution: 65.0g / L, magnesium sulfate 0.5g / L, phosphoric acid: 1.7ml / L, molasses: 7.0g / L, vitamin H: 18.0ug / L, vitamin B1: 13.0ug / L, pH: 7.3.

Embodiment 3

[0038] Experiments were carried out using the same process parameters as in Example 1, except that the ratio of the fermentation medium used was 150 ml / L of rice protein hydrolyzate, i.e. aminopeptide nitrogen 1.8 g / L, soybean oil: 1.0 g / L, rice enzyme Sugar solution: 65.0g / L, magnesium sulfate 0.5g / L, phosphoric acid: 1.7ml / L, molasses: 7.0g / L, vitamin H: 18.0ug / L, vitamin B1: 13.0ug / L, pH: 7.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com