Method for recovering and using machine sealing water during monoammonium phosphate production

A monoammonium phosphate and water recovery technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of increasing sewage treatment volume, increasing sewage treatment cost, waste of process water, etc., to reduce sewage treatment cost and reduce sewage treatment The effect of small amount and input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

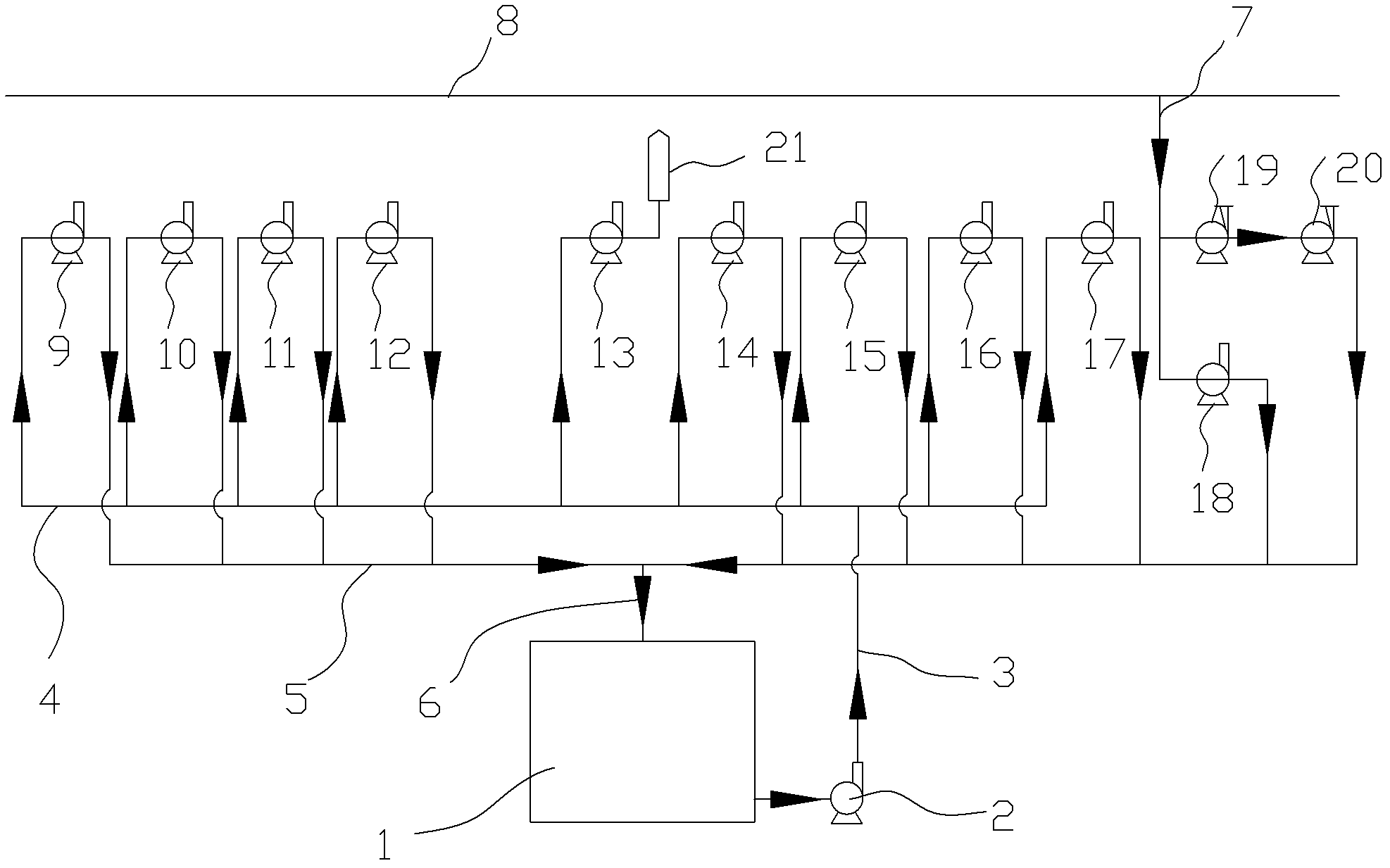

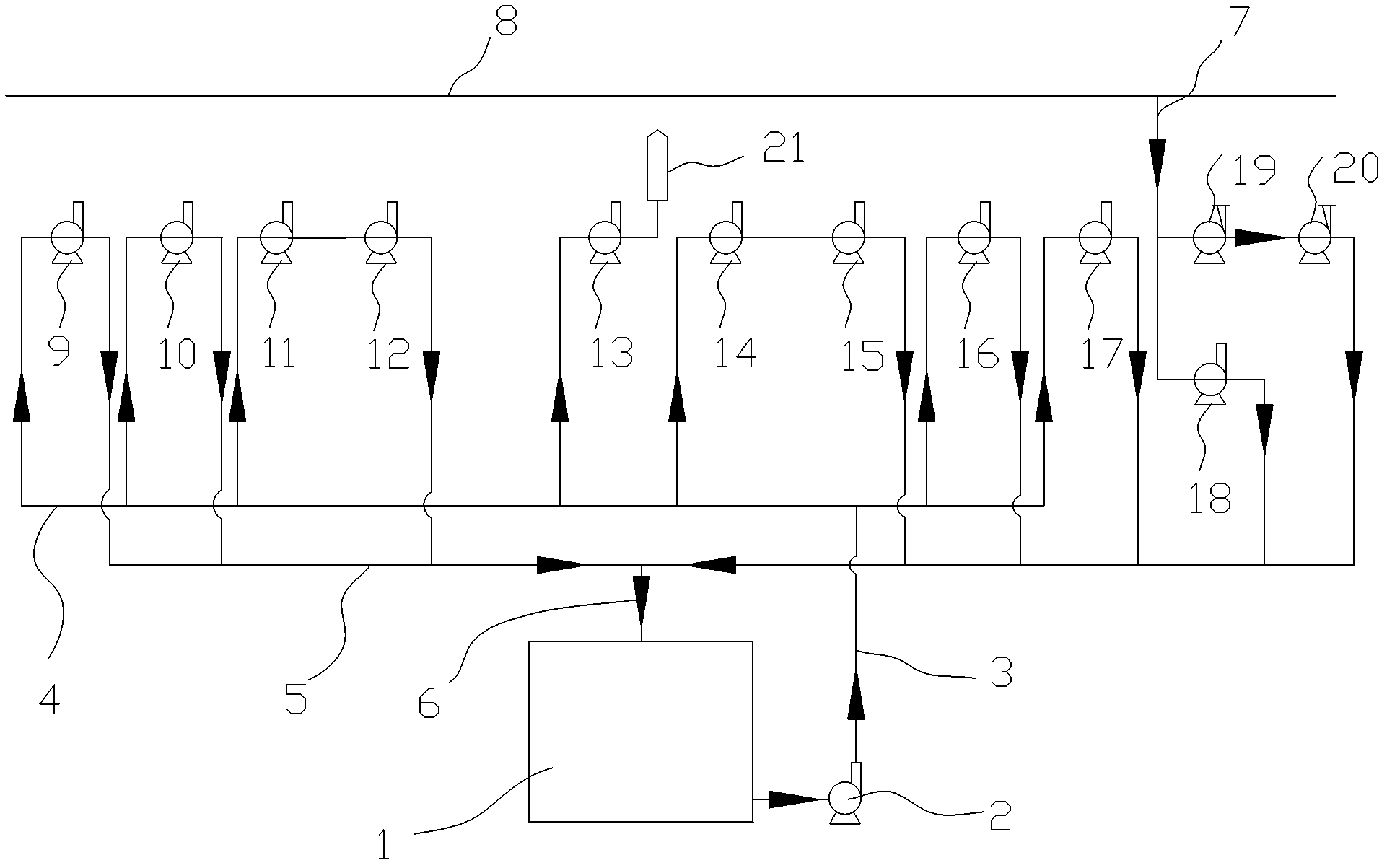

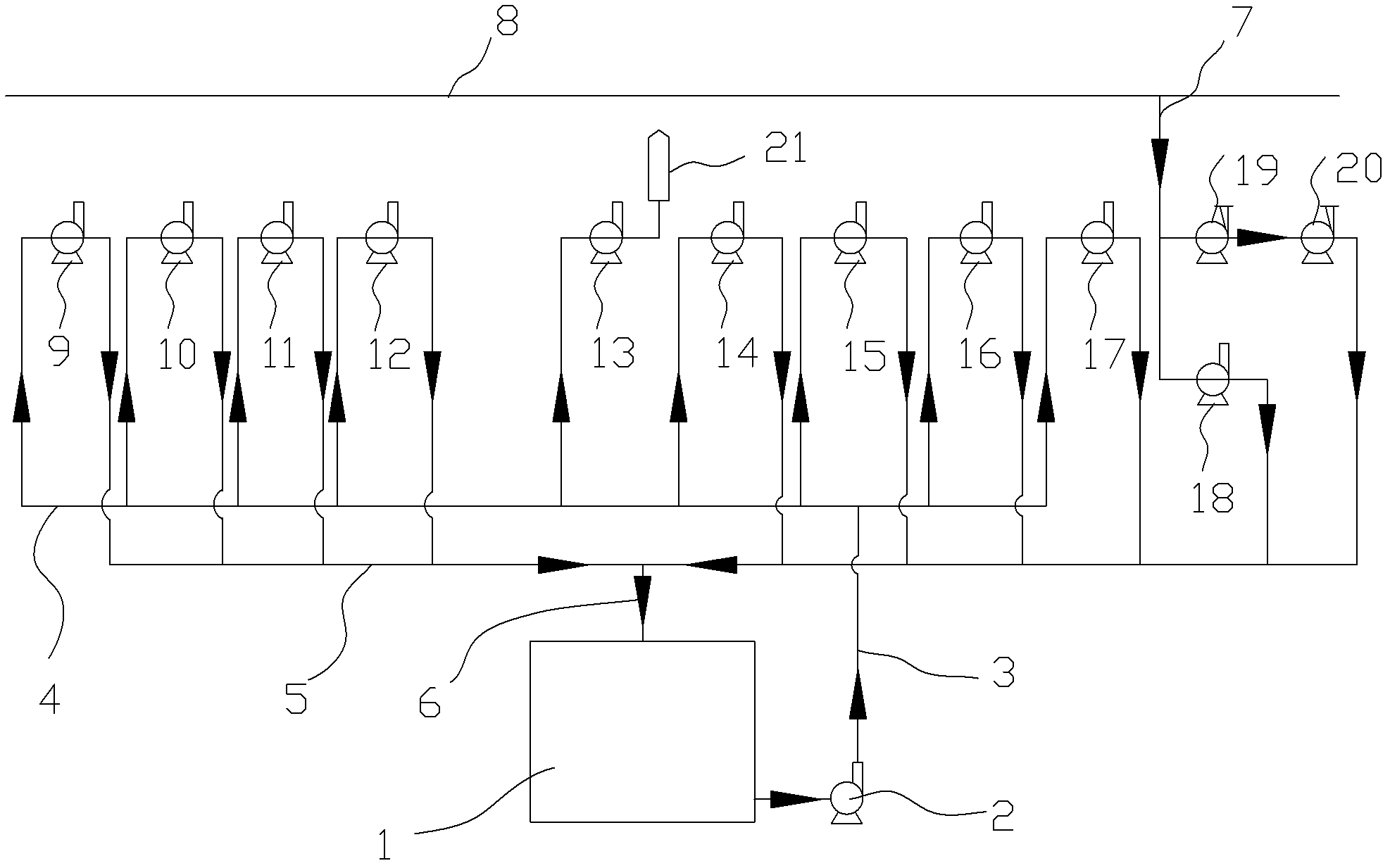

[0012] Such as figure 1 As shown, the present invention includes a circulating water tank 1, a circulating pump 2, a water supply main pipe 4 and a water return main pipe 5. The circulating water tank 1 is transported by the circulating water tank 1 to the water supply main pipe 4 by the circulating pump 2, and the mechanical seals discharged by each pump The water is collected through the return water main pipe 5 and then flows back into the circulating water tank 1 through the pipeline 6 .

[0013] Mechanical seals of dilute acid delivery pump 9, reaction circulation pump 10, second-effect circulation pump 11, first-effect circulation pump 12, exhaust gas scrubbing pump 14, washing displacement pump 15, second-effect condensate water circulation pump 16 and first-effect condensate water delivery pump 17 The water inlet and outlet pipes communicate with the water supply main pipe 4 and the return water main pipe 5 respectively.

[0014] One end of the circulating water reple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com