Production device and method for co-production of alpha-semi-hydrated gypsum by two-step wet-process phosphoric acid

A technology of hemihydrate gypsum and wet-process phosphoric acid, which is applied in the fields of chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex preparation procedures of α-hemihydrate gypsum, low utilization rate of phosphogypsum resources, and concentrated dihydrate acid Low-level problems, to achieve the effect of saving steam consumption, remarkable energy-saving effect, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

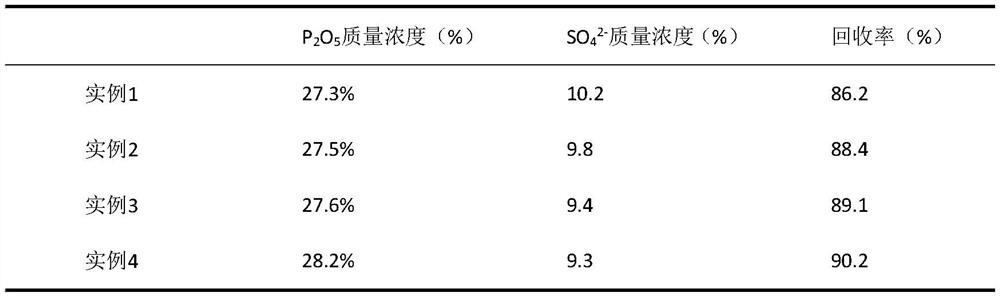

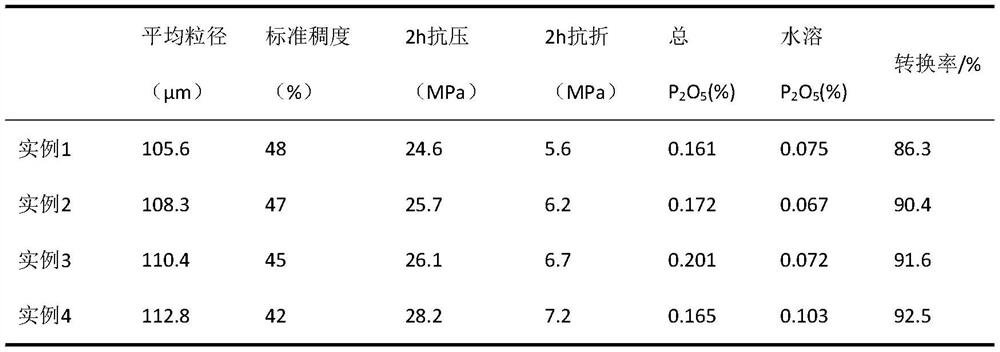

Examples

Embodiment 1

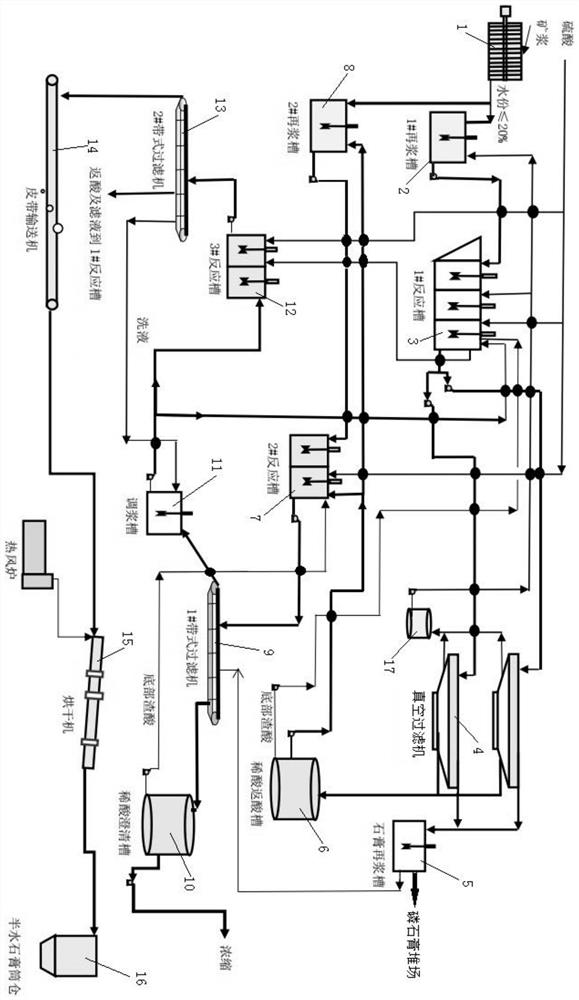

[0032] figure 1 Shown is a production device for two-step wet process phosphoric acid coproduction α-hemihydrate gypsum, comprising successively connected filter press 1, 1# resizing tank 2, 1# reaction tank 3 and vacuum filter 4, vacuum The phosphogypsum outlet of the filter 4 is connected to the gypsum re-slurry tank 5, the slag acid outlet at the bottom of the vacuum filter 4 is connected to the 1# reaction tank 3, the filtrate outlet of the vacuum filter 4 is connected to the dilute acid back-acid tank 6, and the dilute acid back-acid tank 6 The dilute acid outlet is connected to 2# reaction tank 7 and 2# re-slurry tank 8 in turn, and 2# re-slurry tank 8 is connected to filter press 1; the reaction slurry outlet of 2# reaction tank 7 is connected to 1# belt filter 9 connections, 1# belt filter 9 filtrate outlet is connected to dilute acid clarification tank 10, 1# belt filter 9 phosphogypsum outlet is connected to slurry mixing tank 11, 3# reaction tank 12, 2# belt filter ...

Embodiment 2

[0039] (1) Use the filter press 1 to dehydrate the phosphate rock slurry, so that its water content is controlled at 20%, to obtain a press filter cake. The obtained press filter 2 / 3 pulp is sent to 1# reslurry tank 2, and 1 / 3 press filter cake is sent to 2# reslurry tank 8.

[0040] (2) Transport the ore pulp obtained from 1# re-slurry tank 2 to 1# reaction tank 3, and add concentrated sulfuric acid (concentration 98% sulfuric acid). control slurry P 2 o 5 The mass concentration is 23.5%, SO 4 2- The mass concentration is 25 mg / L, the solid content of the slurry is 31%, and the reaction temperature is 80° C. to obtain dihydrate phosphogypsum slurry a.

[0041] (3) dihydrate phosphogypsum slurry a is pumped to vacuum filter 4 for vacuum filtration, and the dilute phosphoric acid (P 2 o 5 Mass concentration 23%) is transported to dilute acid return acid tank 6 as system acid return, transported to 2# reaction tank 7 and 2# re-sizing tank 8 for use as pulping, and the slag...

Embodiment 3

[0049] (1) Use the filter press 1 to dehydrate the phosphate rock slurry, so that its water content is controlled at 20%, to obtain a press filter cake. 2 / 3 of the obtained press filter cake is delivered to 1# resizing tank 2, and 1 / 3 of the press filter cake is delivered to 2# resizing tank 8.

[0050] (2) Transport the ore pulp obtained from 1# re-slurry tank 2 to 1# reaction tank 3, and add concentrated sulfuric acid (concentration 98% sulfuric acid). control slurry P 2 o 5 The mass concentration is 24.5%, SO 4 2- The mass concentration is 30 mg / L, the solid content of the slurry is 31%, and the reaction temperature is 80° C. to obtain dihydrate phosphogypsum slurry a.

[0051] (3) dihydrate phosphogypsum slurry a is pumped to vacuum filter 4 for vacuum filtration, and the dilute phosphoric acid (P 2 o 5 Mass concentration 23%) is transported to dilute acid return acid tank 6 as system acid return, transported to 2# reaction tank 7 and 2# re-sizing tank 8 for use as p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com