An all-round automatic cleaning system and its application

An automatic cleaning, all-round technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problem of inability to achieve online cleaning without dead ends, reduce the risk of mildew, and save processes. The effect of using water and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: All-round automatic cleaning system

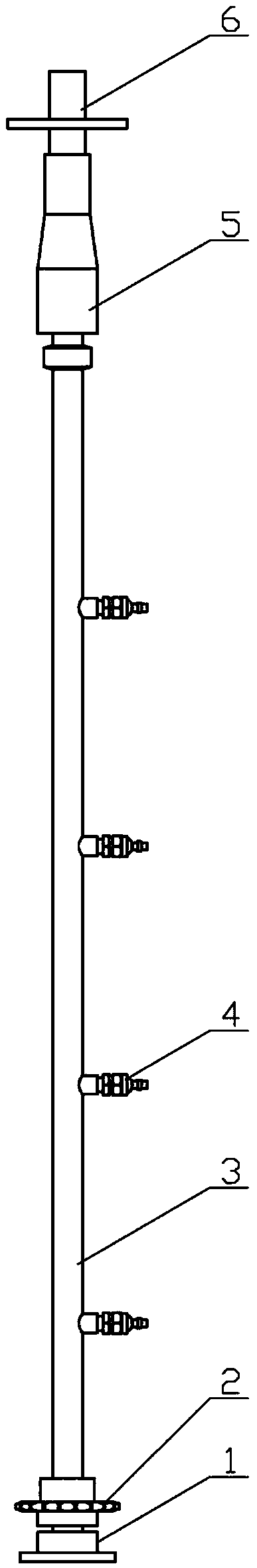

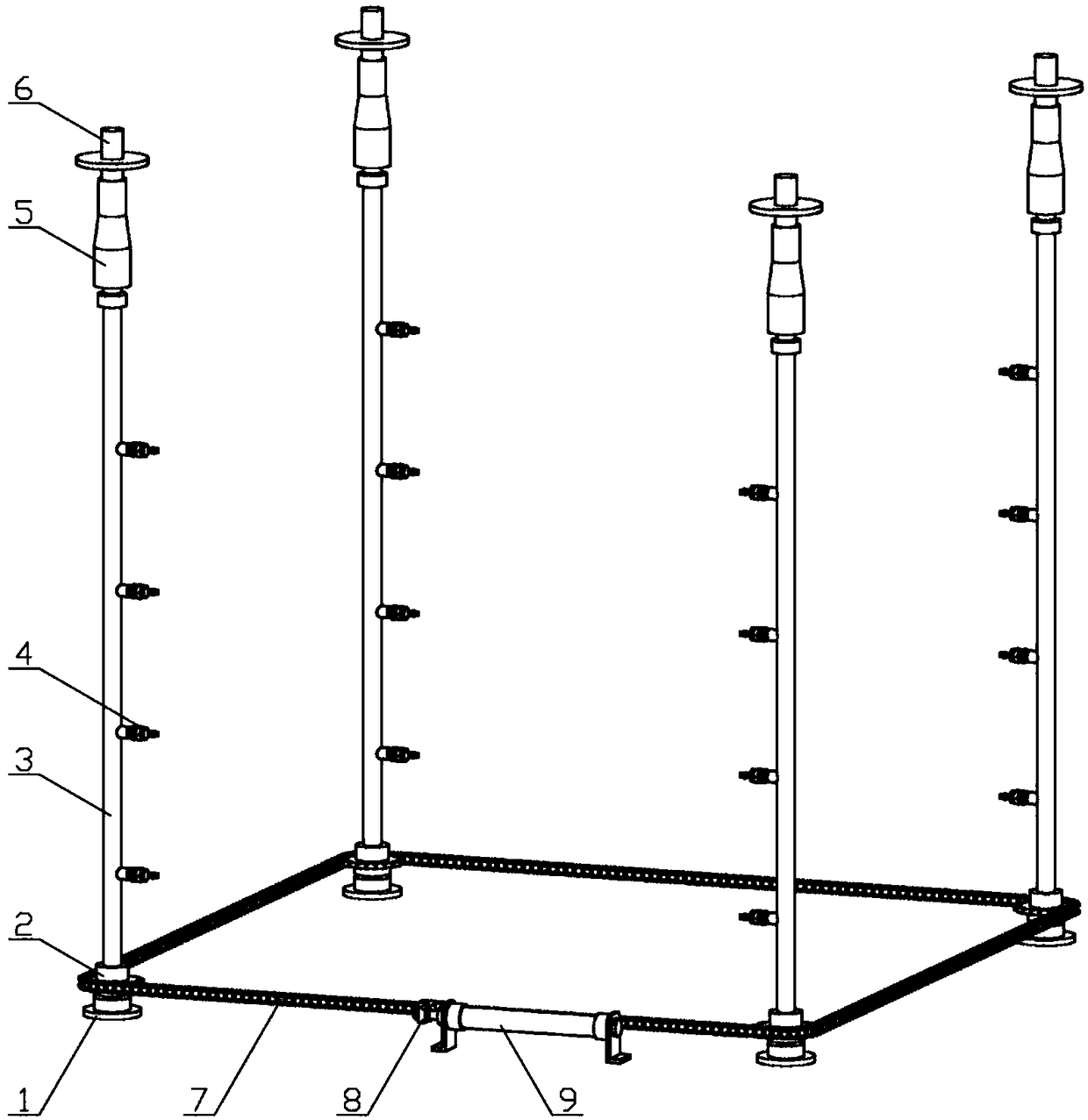

[0036] See attached figure 1 with 2 As shown, the all-round automatic cleaning system provided by the present invention includes a power transmission assembly, a spray water pipe (3), a connection assembly and a power assembly, the power transmission assembly includes a sprocket (2) and a chain (7), and the connection assembly includes a bearing Seat (1), rotary seal assembly (5) and connecting member (8), the power assembly and the chain (7) are connected through the connecting member (8), and the chain (7) meshes with the sprocket (2) to form a closed The bearing housing (1) is provided under the sprocket (2), the upper end of the sprocket (2) is connected to one end of the spray water pipe (3), and the water inlet (6) set at the other end of the spray water pipe (3) passes through The rotary sealing assembly (5) is connected with the spray water pipe (3).

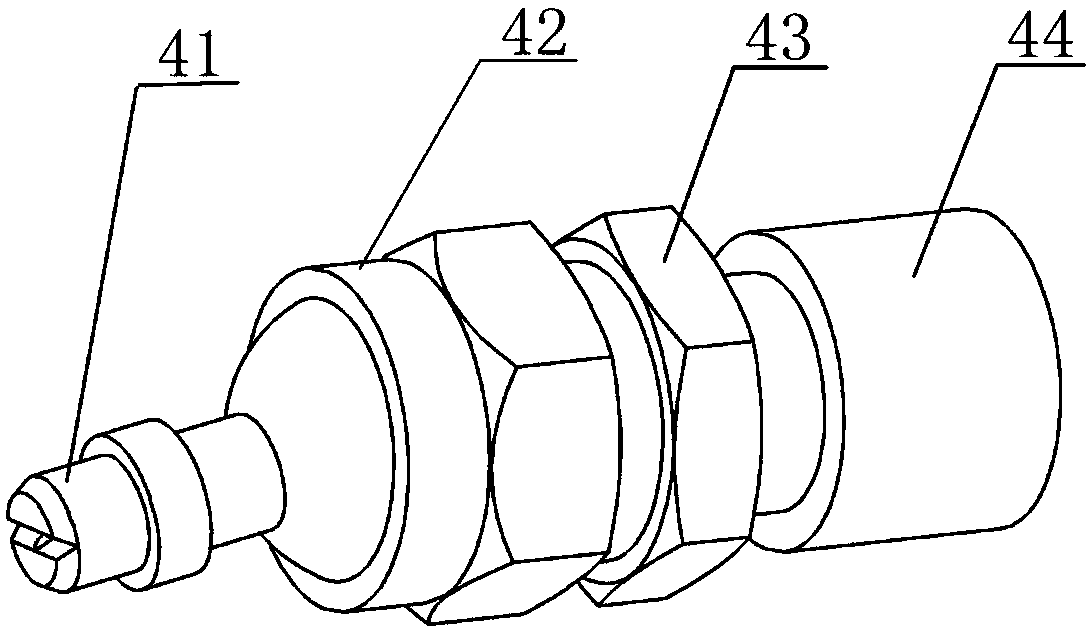

[0037] See attached image 3 As shown, in the present i...

Embodiment 2

[0043] Embodiment 2: The working principle of the all-round automatic cleaning system

[0044]After the cleaning liquid is injected from the water inlet (6), it passes through the rotary seal assembly (5) and enters the spray water pipe (3), and is sprayed out in a fan shape through the angle-adjustable fan nozzle (4); at the same time, the stainless steel diaphragm The cylinder (9) is started, driving the chain (7) to make a reciprocating motion with a certain stroke, so that the sprocket also rotates together, and finally makes the angle-adjustable fan nozzle (4) follow each spray water pipe (3) back and forth for a quarter One circular arc rotation, according to different application occasions according to the needs, according to the cleaning conditions, the corresponding number of spray water pipes (3) can be installed, and the fan nozzle (4) can be adjusted within the range of 0 ~ 45 degrees before the cleaning process starts The initial angle enables the cleaning system ...

Embodiment 3

[0045] Embodiment Three: Application of All-round Automatic Cleaning System

[0046] See attached Figure 4 And attached Figure 5 , when the all-round automatic cleaning system described in Embodiment 1 is used in the food industry and pharmaceutical industry such as freeze-drying machines and edible fungus cultivation beds, it is especially suitable for large-scale closed spaces such as large-scale freeze-dryers or closed large-scale edible fungus cultivation beds. In the cleaning and disinfection operation without dead ends inside the equipment, start the electrical control system, and use different control valves to make the high-pressure water pump deliver the cleaning liquid from the liquid storage tank to the cleaning system and the air compressor to the stainless steel cylinder of the cleaning system. Convey air to make it reciprocate and convert power to drive the cleaning system to work.

[0047] The electrical control system includes a microcomputer time program c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com