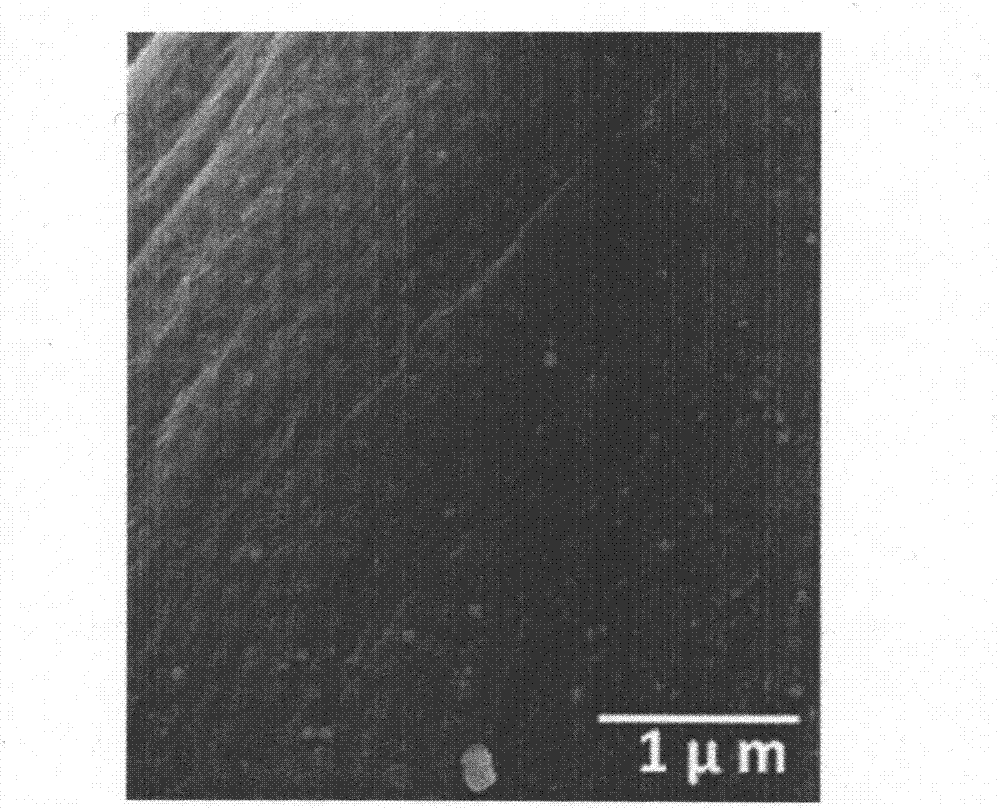

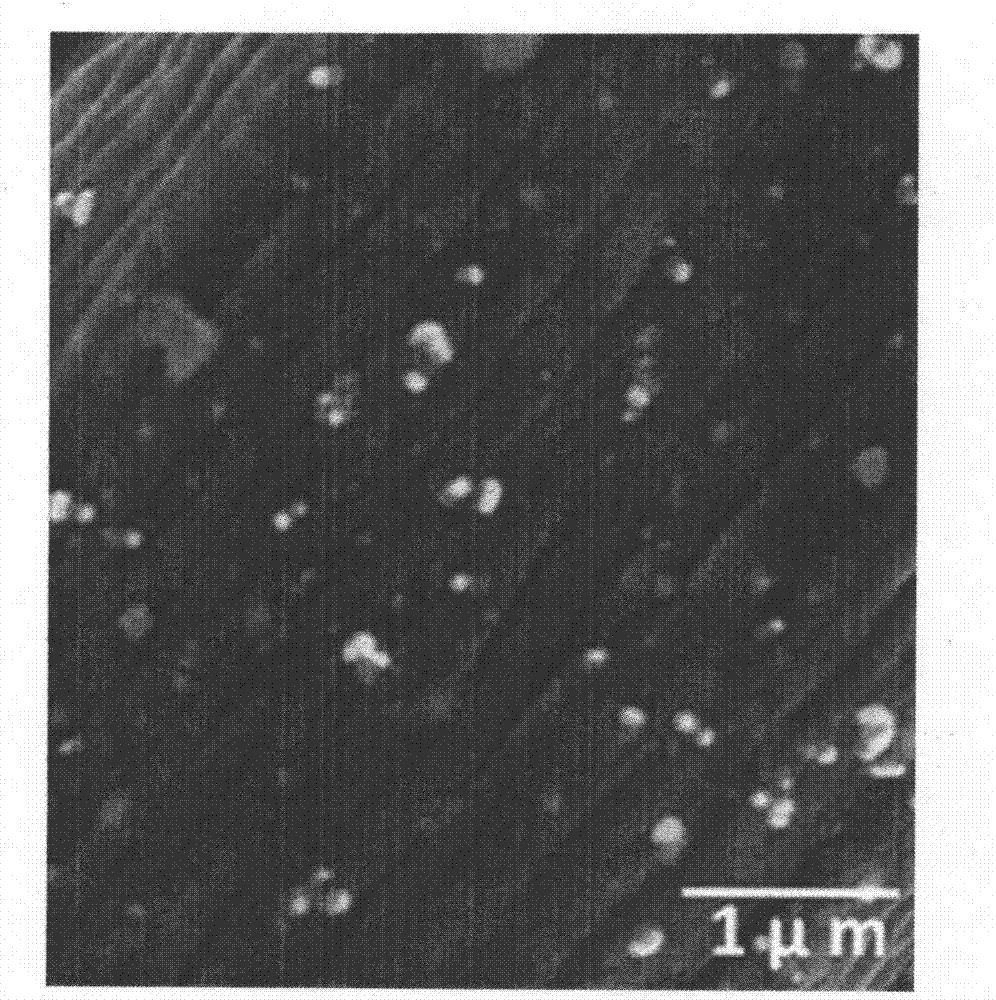

Cellulose fiber-supported nano silver antibacterial material and preparation method thereof

A cellulose fiber, nano-silver antibacterial technology, applied in the direction of chemical post-treatment of artificial filaments and cellulose/protein artificial filaments in cellulose solution, can solve the problems of synthetic preparation process pollution, poor washing resistance, etc. The effect of great application value, improved security, and rich sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Under the temperature condition of 20 ℃ of water baths, 1.0g 60 mesh jute fiber powders are soaked in the stirred tank that fills 50g mass fraction and are 15% sodium hydroxide solution, stir 120min with the stirring speed of 300rpm, then use vacuum pump Suction filtration, washing the jute fiber powder of gained to neutrality, carry out drying in vacuum oven, vacuum tightness is 0.1MPa, and drying temperature is 60 ℃, and drying time is 12h, obtains the jute fiber powder of alkali treatment;

[0049] (2) Under the temperature condition of 4 ℃ of water baths, take by weighing the alkali-treated jute fiber powder that 1g the first step gains and join in the stirred tank that 50g contains TEMPO 0.001g, NaClO 15g and NaBr 0.01g aqueous solution, stirring speed is 500rpm , drop 1% sodium hydroxide to adjust the pH value of the system at 10.5, use a pH meter to monitor in real time, when the pH value is constant and no longer consume sodium hydroxide, add 5ml of absolute ...

Embodiment 2

[0055] (1) Under the temperature condition of 80 ℃ of water baths, 20g60 purpose flax fiber powders are soaked in the mass fraction that fills 200g and be 20% sodium hydroxide solution stirring tank, stir 100min with the stirring speed of 300rpm, then use vacuum pump suction filtration, The flax fiber powder obtained was washed to neutrality, and dried in a vacuum oven with a vacuum degree of 0.1 MPa, a drying temperature of 80° C., and a drying time of 6 hours to obtain alkali-treated flax fiber powder;

[0056] (2) under the temperature condition of 20 DEG C, the flax fiber powder of the pretreatment that takes 1g second step gains joins in the stirring kettle that fills 99g and contains the aqueous solution of TEMPO 0.001g, NaClO 10g and NaBr0.01g, and stirring speed is 500rpm, add dropwise 1% sodium hydroxide solution to adjust the pH value of the reaction system to 11, use a pH meter to monitor in real time, and when the pH value is constant and no longer consume sodium hy...

Embodiment 3

[0062] (1) under 60 ℃ of water-bath temperature conditions, 1g60 purpose jute fiber powder is soaked in the mass fraction that fills 40g and is in the stirred tank of 16% sodium hydroxide solution, stirs 300min with the stirring speed of 200rpm, then uses vacuum pump suction filtration, The jute fiber powder of gained is washed to neutrality, is dried in vacuum oven, and vacuum degree is 0.1MPa, and drying temperature is 70 ℃, and drying time is 12h, obtains the jute fiber powder of alkali treatment;

[0063] (2) under the temperature condition of 60 ℃ of water baths, the jute fiber powder of the pretreatment that takes 1.0g the second step gains joins into 99g and contains TEMPO 0.002g, NaClO 2 1.2g and 12g of NaClO in a stirred tank with a stirring speed of 500rpm, add 1% glacial acetic acid solution dropwise to adjust the pH of the reaction system to 4.8, use a pH meter to monitor in real time, and when the pH value is constant and no longer consume glacial acetic acid, add ...

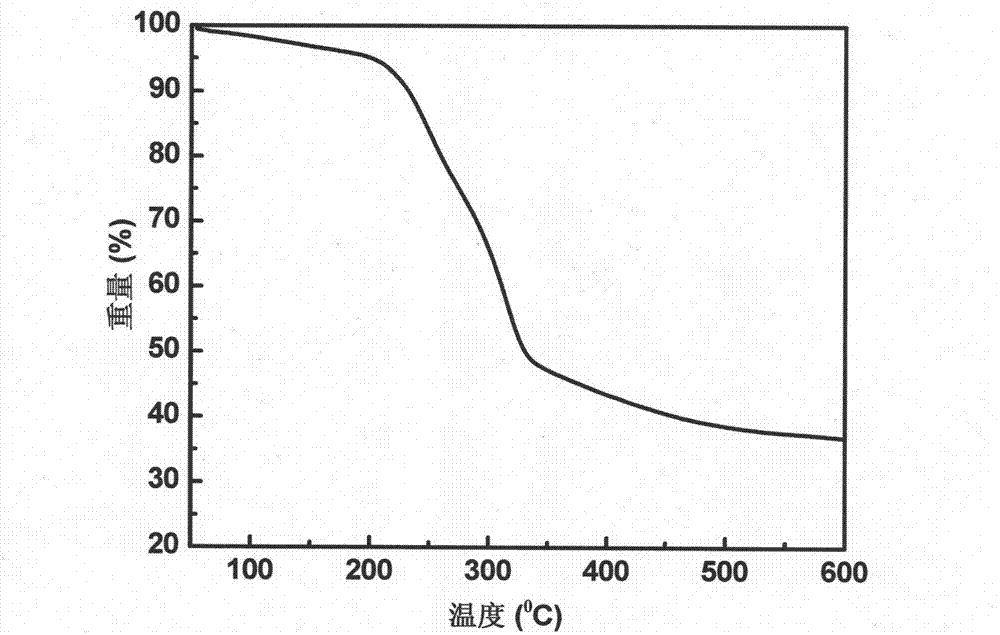

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com