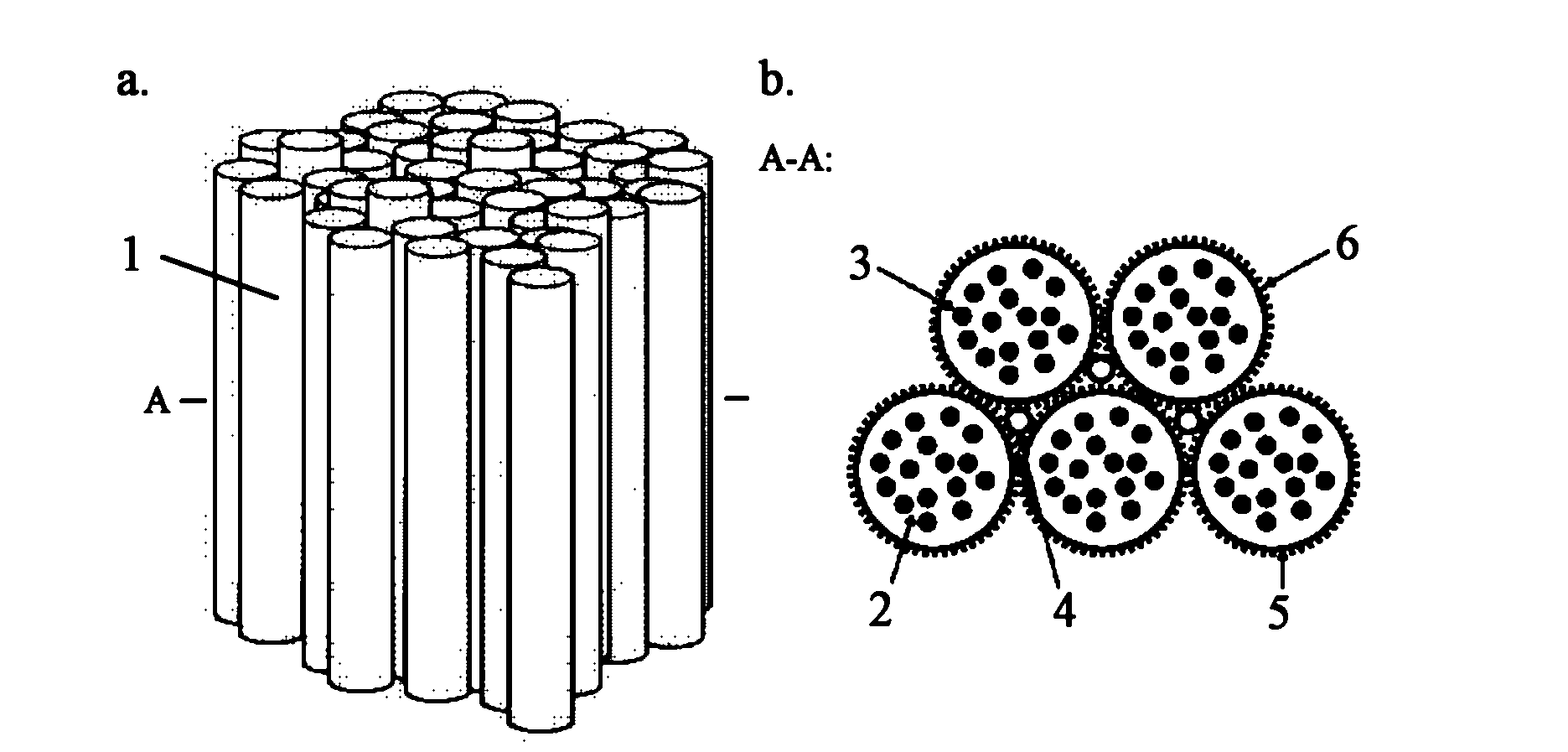

Tissue engineering fiber bundle structure body and preparation method thereof

A technology of fiber filaments and hydrogel fibers, applied in the biological field, can solve the problems of complex forming process and difficult control of internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

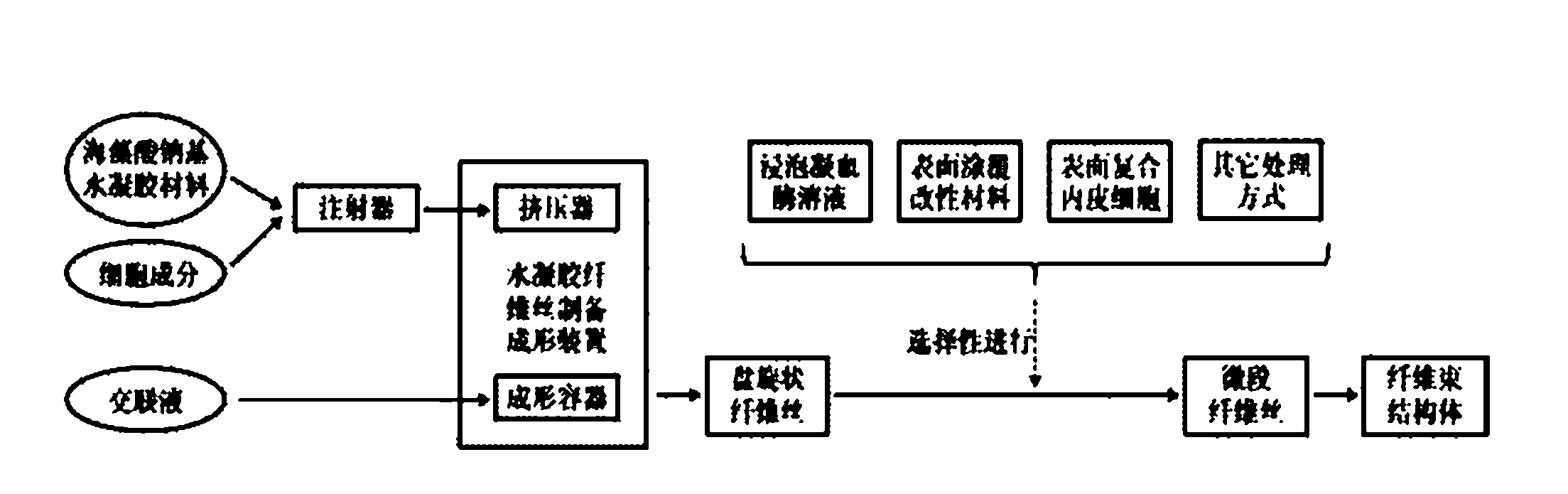

Method used

Image

Examples

Embodiment 1

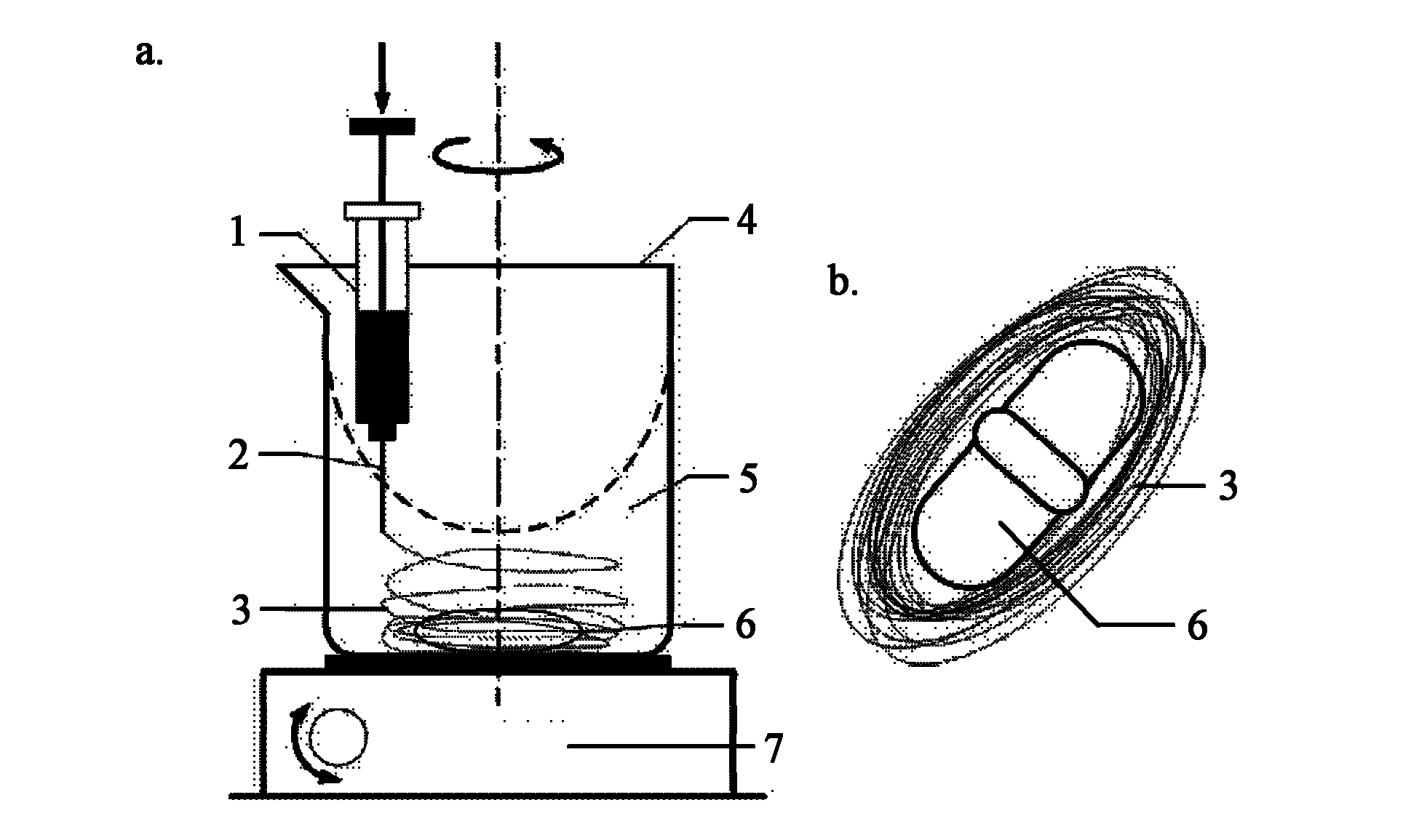

[0109] Embodiment 1, matrix material is the forming construction of the hydrogel fiber silk of sodium alginate / cell culture fluid

[0110] 1. The formation and construction of hydrogel fiber filaments with sodium alginate / cell culture medium as the matrix material

[0111] 1) Solution preparation

[0112] Prepare a 0.05 g / ml sodium alginate aqueous solution, place it at 60° C. to dissolve it completely, and perform sterilization treatment.

[0113] Prepare 0.05g / ml calcium chloride aqueous solution and sterilize it.

[0114] Preparation of cell culture fluid A: It is obtained by mixing fetal bovine serum, penicillin, streptomycin and high-sugar DEME culture fluid, the concentration of said fetal bovine serum in said cell culture fluid is 10% (volume percentage), so The concentration of said penicillin and streptomycin in said cell culture medium is 100U / ml.

[0115] Preparation of cell culture medium B: high-sugar DEME medium, Invitrogen Cat. No. 12800-017), placed at 4°C f...

Embodiment 2

[0124] Example 2. Forming and construction of sodium alginate hydrogel fiber filaments containing cardiomyocytes and wrapping endothelial cells

[0125] 1. Formation and construction of sodium alginate hydrogel fibers containing cardiomyocytes and wrapping endothelial cells

[0126] 1) Solution preparation

[0127] Prepare 2.5% sodium alginate aqueous solution and 0.05 g / ml calcium chloride aqueous solution in the same manner as in Example 1.

[0128] Preparation of cardiomyocyte suspension, isolated cardiomyocytes were extracted from sacrificed neonatal suckling mice (purchased from the Experimental Animal Center of Peking University Health Science Center, Sprague-Dawley rats), cultured in cell culture solution A, and placed in a 37°C carbon dioxide incubator for standby . 75cm of cardiomyocytes will be overgrown when used 2 Aspirate the cell culture solution in the cell culture bottle, add 2ml of cell digestion solution, shake gently to make it cover the bottom of the bot...

Embodiment 3

[0150] Embodiment 3, matrix material is the shaping construction of the hydrogel fiber silk of sodium alginate / fibrin

[0151] 1. Forming and construction of hydrogel fiber filaments with sodium alginate / fibrin as the matrix material

[0152] 1) Solution preparation

[0153] Prepare 5% (0.05g / ml) sodium alginate aqueous solution and 0.05g / ml calcium chloride aqueous solution with embodiment 1.

[0154] Preparation of 5% fibrinogen solution: fibrinogen (purchased from Sigma, product number F8630) was dissolved in DEME high-glucose culture medium, and placed at 37° C. to dissolve completely.

[0155] Preparation of 30 U / ml thrombin solution: prepare a thrombin solution (purchased from Sigma, product number T4648) with DEME high-sugar culture medium at a concentration of 30 U / ml, and place it at 4°C for use.

[0156] Preparation of cell culture fluid A: It is obtained by mixing fetal bovine serum, penicillin, streptomycin and high-sugar DEME culture fluid, the concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com